Sand charging device used during fracturing or slotting under coal mine and sand charging control method

A fracturing and slotting technology, which is applied in the field of sand adding devices in coal mine hydraulic fracturing or slotting process, can solve the problems of limited slotting capacity, unsatisfactory mixing ratio of sand and water, and high labor intensity, and achieve the goal of manufacturing and low cost of use, convenient transportation up and down wells, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

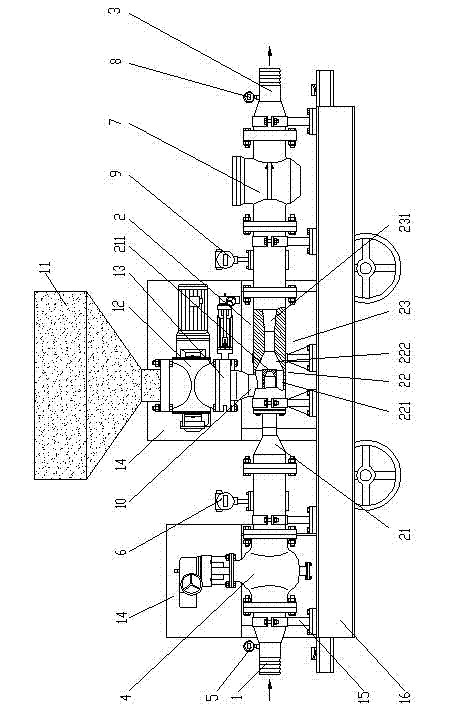

[0033]Example 1 see figure 1 , a coal mine underground fracturing or slotting sanding device, comprising a water inlet pipe 1, a mixing pipe 2, and a water outlet pipe 3 connected in sequence, the inlet end of the water inlet pipe 1 is used to connect with a water source, and the pipeline of the water inlet pipe 1 There is a first electric valve 4, a first digital pressure gauge 5, and a first electromagnetic flowmeter 6; the outlet end of the water outlet pipe 3 is used to connect with the fracturing or slotting medium inlet of the medium pressurization pump group, and the water outlet pipe 3 The pipeline is provided with a check valve 7, a second digital pressure gauge 8, and a second electromagnetic flowmeter 9; the mixing pipe 2 is connected to a hopper 11 for containing sand through a sand feeding pipe 10, and the hopper 11 is located in the mixing pipe 2 Above, an electric discharge valve 12 and an electric gate valve 13 are provided on the pipeline of the sand feeding p...

Embodiment 2

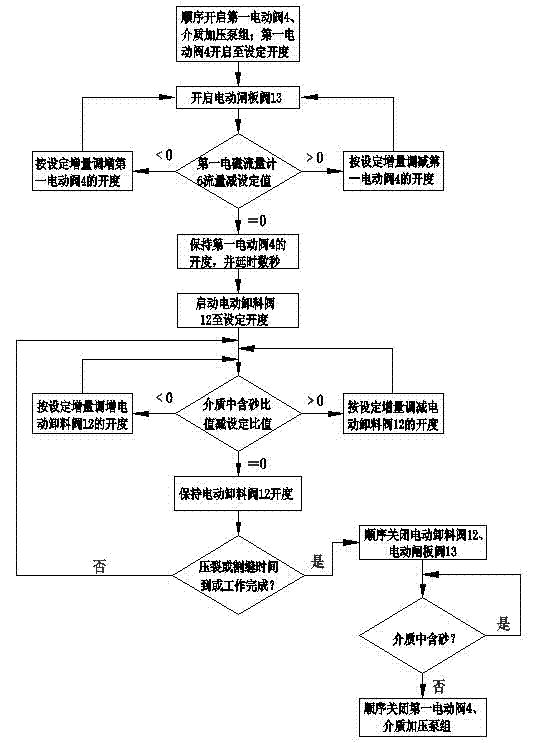

[0038] Example 2 see figure 1 , figure 2 , a sanding control method for fracturing or slotting in a coal mine, an automatic control system for controlling the sanding device described in Embodiment 1 of the present invention is provided, and the automatic control system performs sanding control according to the following steps:

[0039] a. Open the first electric valve 4 and the medium pressurizing pump group sequentially, and open the first electric valve 4 to the set opening degree;

[0040] b. Open the electric gate valve 13;

[0041] c. Collect the flow digital signal of the first electromagnetic flowmeter 6 and compare it with the set value of the influent flow. When the flow value of the first electromagnetic flowmeter 6 is less than the set value, perform step d; when the first electromagnetic flowmeter 6 When the flow value of the first electromagnetic flowmeter 6 is greater than the set value, execute step e; when the flow value of the first electromagnetic flowmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com