Creep aging bidirectional tension-compression testing device

A creep aging and test device technology, applied to measuring devices, instruments, scientific instruments, etc., to achieve the effect of easy installation, simple structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

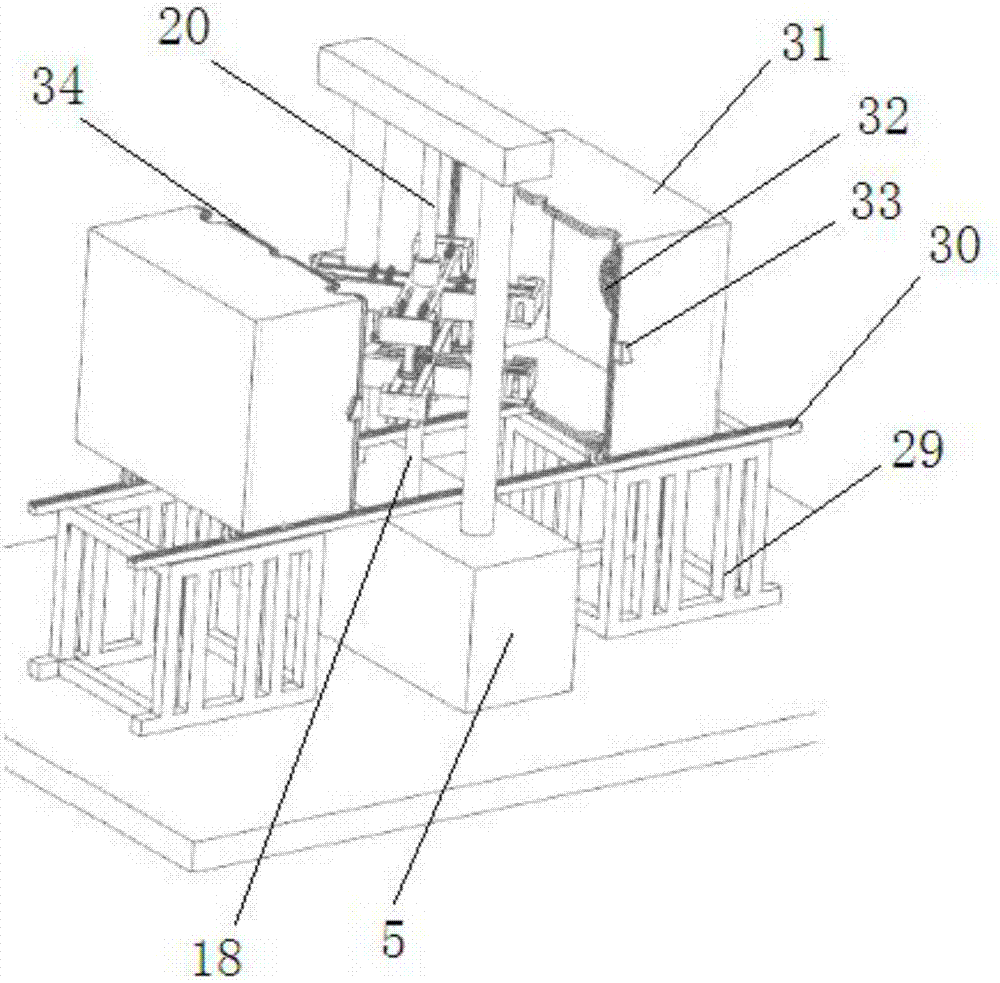

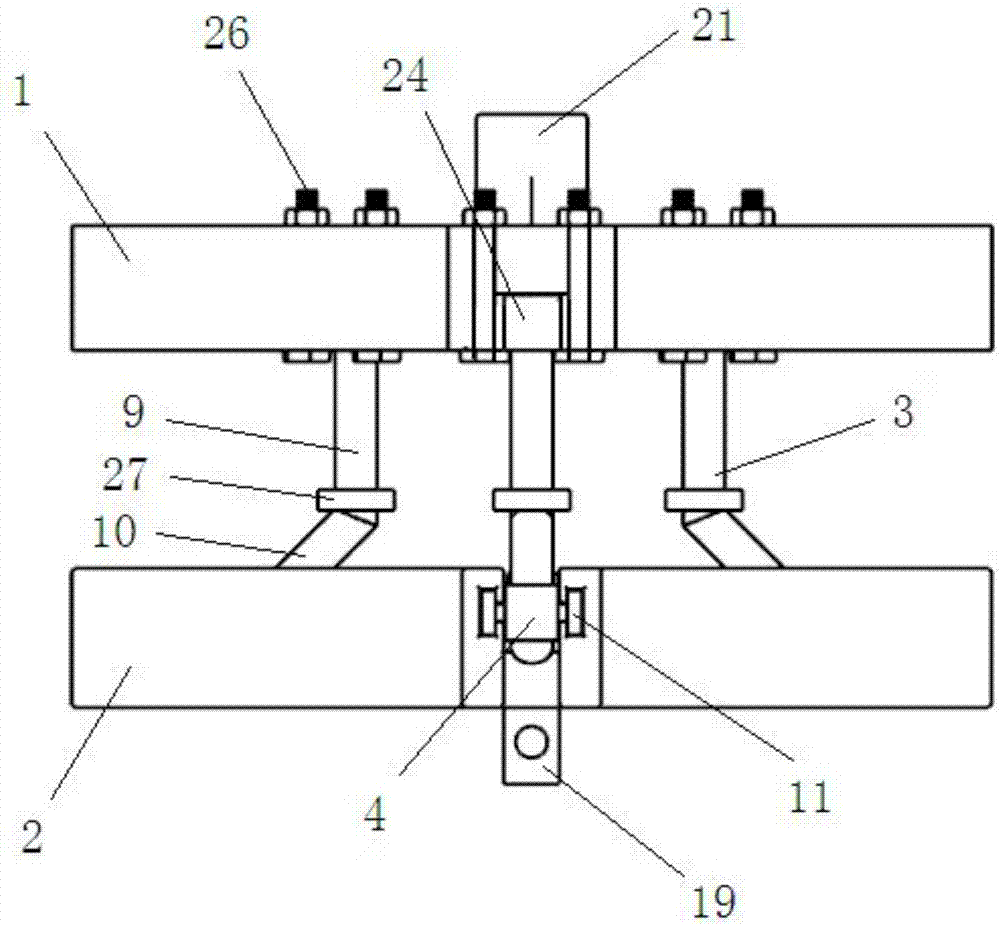

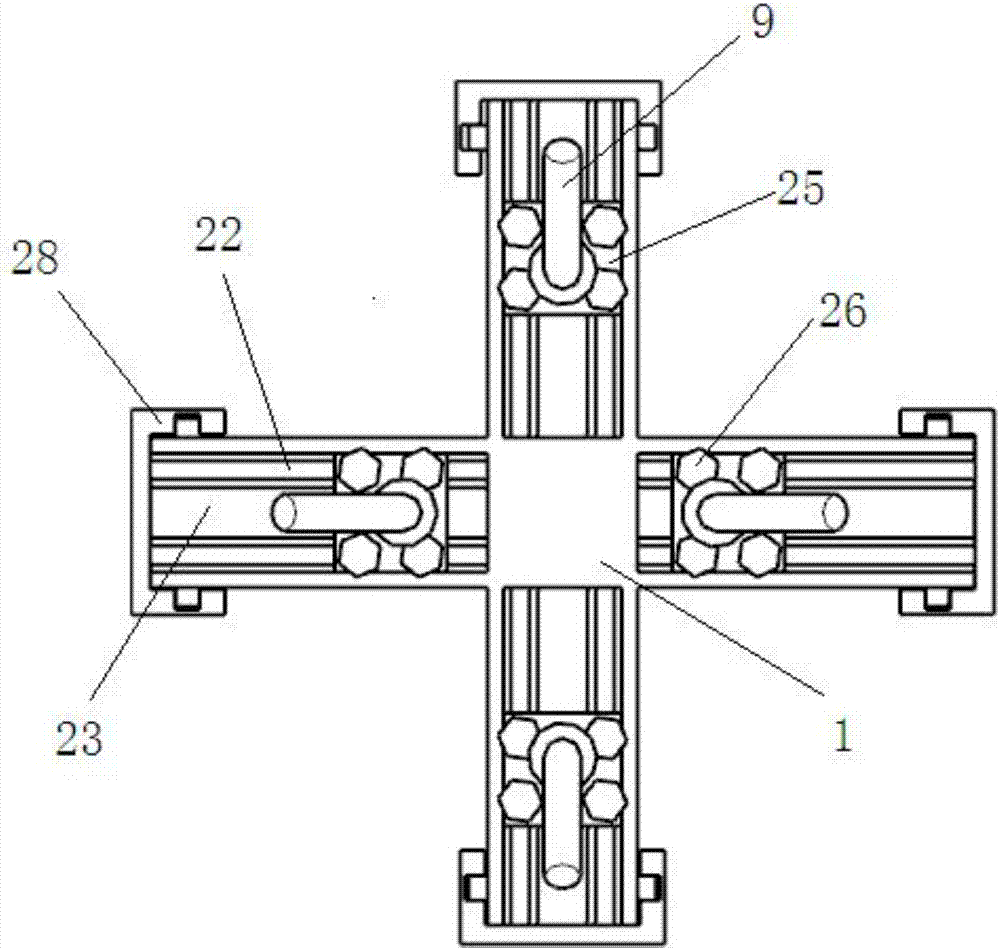

[0050] see Figure 1-Figure 6 , a creep aging bidirectional tension and compression test device, including an upper cross support 1, a lower cross support 2, four guide post assemblies 3 and four slider assemblies 4.

[0051] The upper end cross bracket and the lower end cross bracket are arranged on the same central axis from top to bottom, and the central part of the lower end cross bracket is provided with a lower connecting piece 19 connected with the lower connecting rod 18 of the stretching machine 5, the upper end The central portion of the cross bracket is provided with an upper connecting piece 21 connected with the upper connecting rod 20 of the stretching machine 5 and the upper connecting rod provides a vertical upward pulling force for the upper end cross bracket, and the lower connecting piece and the upper connection The components are rod structures and are sleeved and connected with the lower connecting rod and the upper connecting rod respectively.

[0052] ...

Embodiment 2

[0064] See details Figure 7 , the device of this embodiment is mainly used for bidirectional compression test. At this time, as long as the guide post assembly in embodiment 1 is rotated 180° along the axis of the straight guide post, so that the upper ends of the four inclined guide posts are all facing away from the The direction of the free end of the second groove is inclined, and the pulling force of the stretching machine drives the upper cross bracket to move upward, thereby driving the straight guide column and the inclined guide column to move upward, but because the slider can only move horizontally , and the inclined guide post is matched with the inclined hole of the slider, so the end of the inclined guide post pushes the slider to slide toward the free end side of the second groove, so that the slider pushes The free end of the cross-shaped specimen is compressed inwardly.

Embodiment 3

[0066] See details Figure 8 , the device of this embodiment is mainly used for doing a compression test while stretching, combining the structures of Embodiment 1 and Embodiment 2, and controlling the freedom of the upper ends of one set of two opposite inclined guide posts toward the second groove. The end side is inclined, and the upper ends of the other set of two opposite inclined guide posts are inclined toward the free end side away from the second groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com