Air control valve

An air-conditioning valve and adjustment knob technology, which is applied to furnace control devices, furnaces, lighting and heating equipment, etc., can solve the problems of unstable combustion reaction of kilns, large fluctuations in gas pressure, and easy production accidents. Promote use, reduce the risk of gas leakage, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

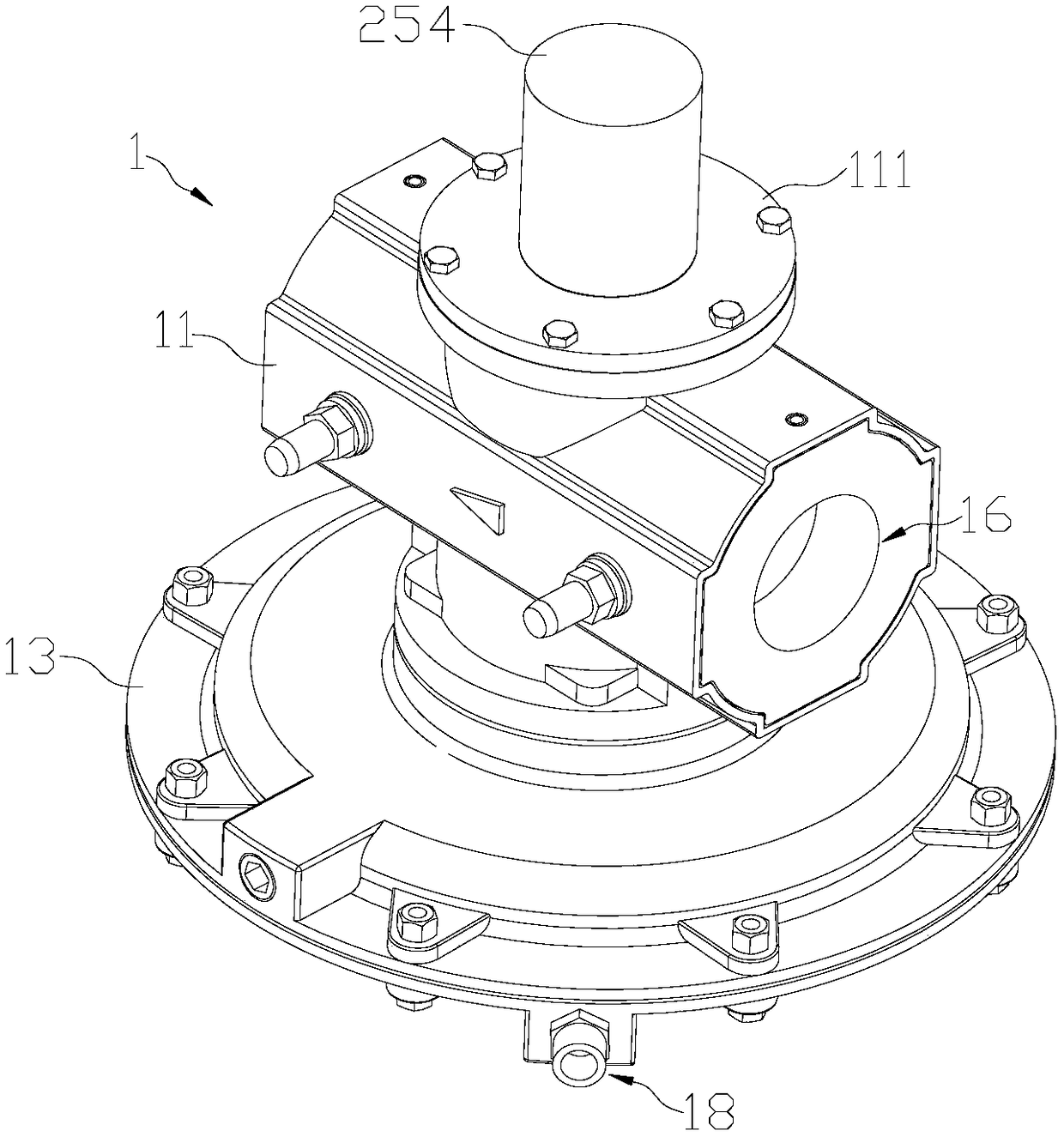

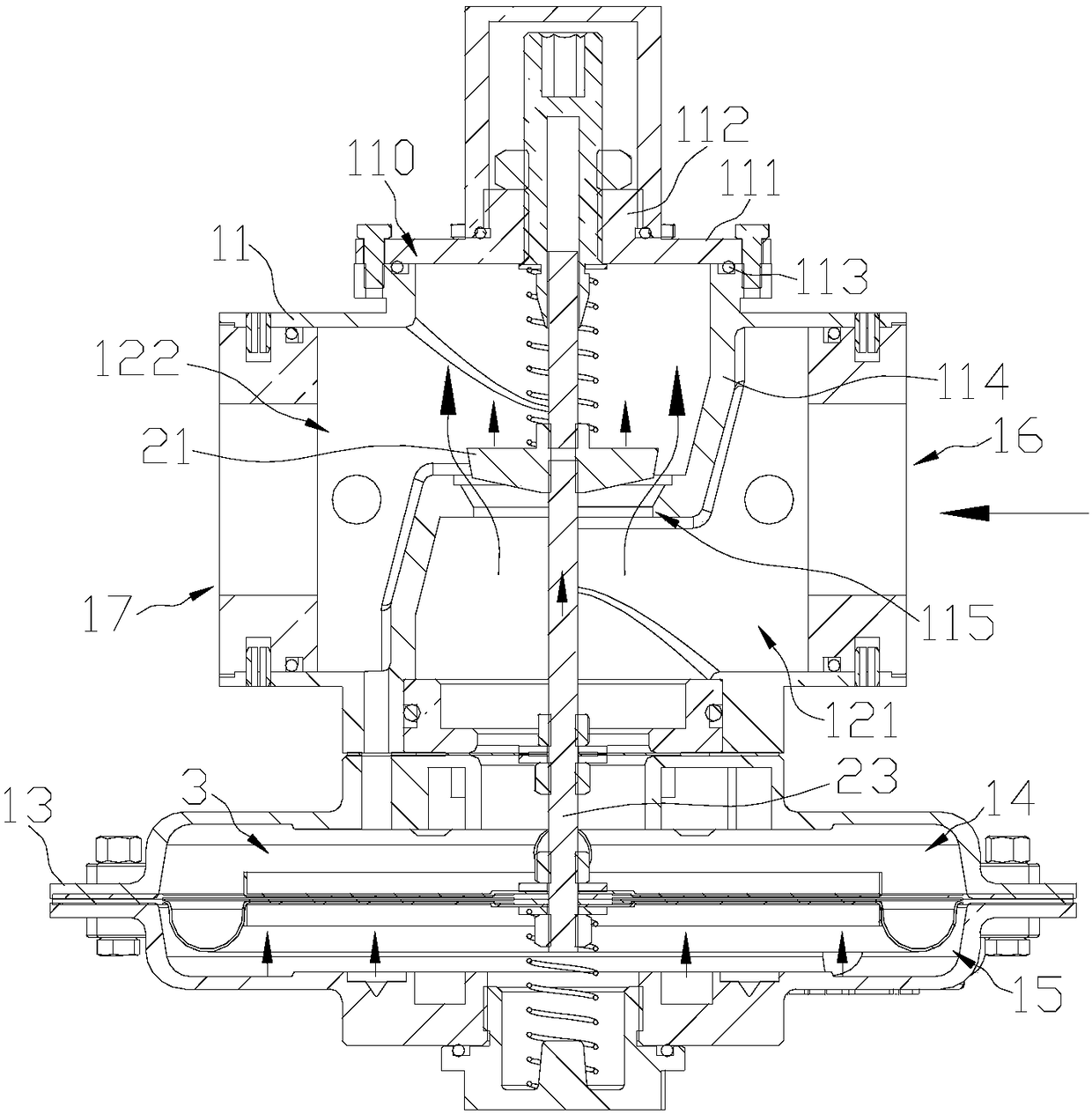

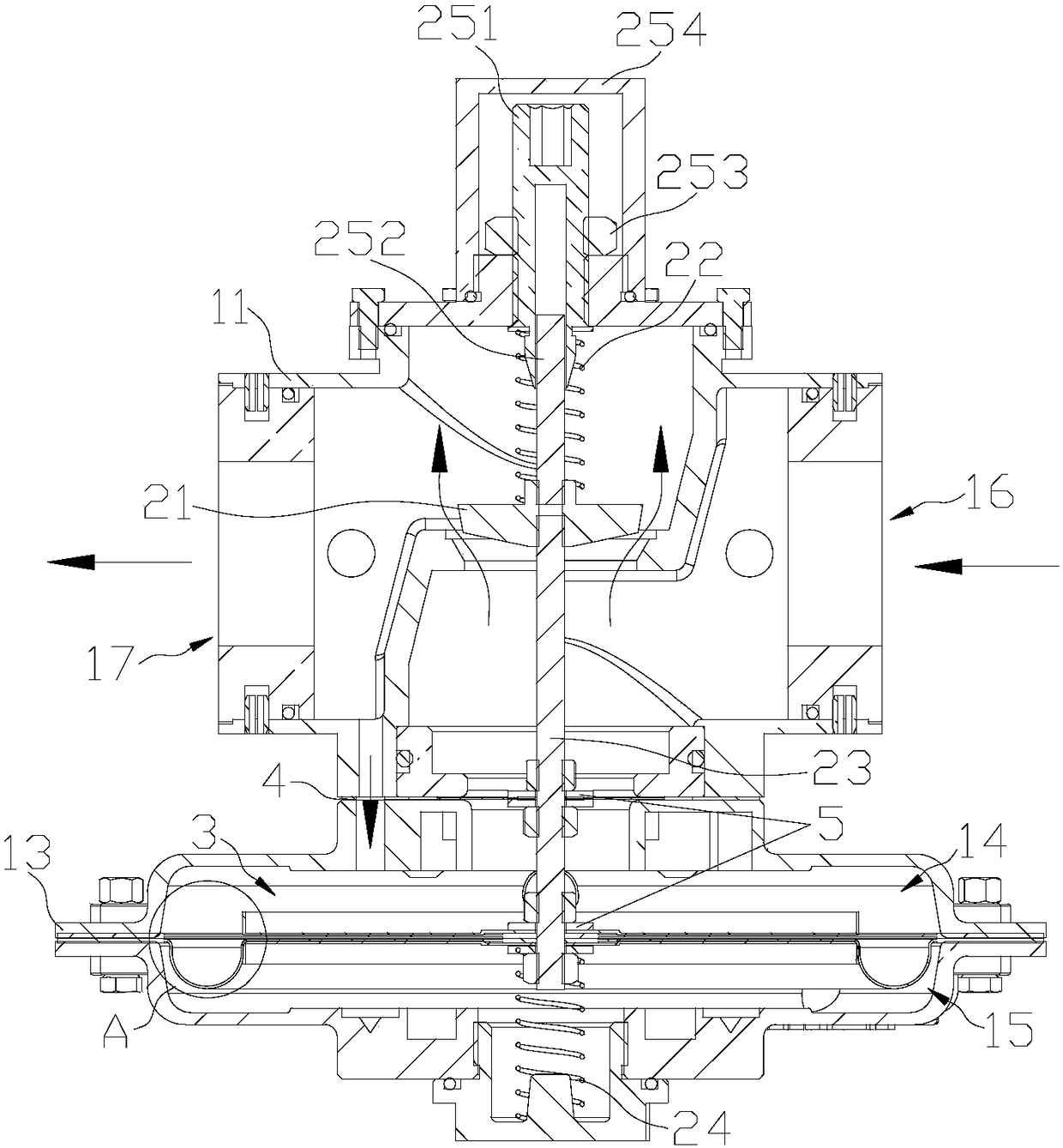

[0034] see Figure 1 to Figure 5 , an air regulating valve, comprising a casing 1, an upper cavity and a lower cavity are arranged in the casing 1, a connecting structure is arranged in the upper cavity, and the connecting structure is used to control the air in the upper cavity flux; the lower cavity is provided with an elastic diaphragm structure 3, and the elastic diaphragm structure 3 is connected to the connection structure through a transmission rod 23; the lower cavity is externally connected to an external gas pipeline (not shown in the figure ), the external gas pipeline can input gas to the lower cavity; the elastic diaphragm structure 3 is deformed and brought to the transmission rod 23 under the pressure of the gas, thereby adjusting the opening of the connecting structure degree of fit.

[0035] The shell 1 includes an upper shell 11 and a lower shell 13, the upper shell 11 is detachably connected to the lower shell 13; the upper cavity is arranged in the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com