SNCR (Selective Non-Catalytic Reduction) denitrification technology test bench

A test bench and technology, applied in the field of SNCR denitrification technology test bench, can solve the problems of test repeatability, influence test accuracy, low ammonia measurement accuracy, etc., to ensure repeatability, reduce adsorption, and ensure measurement. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

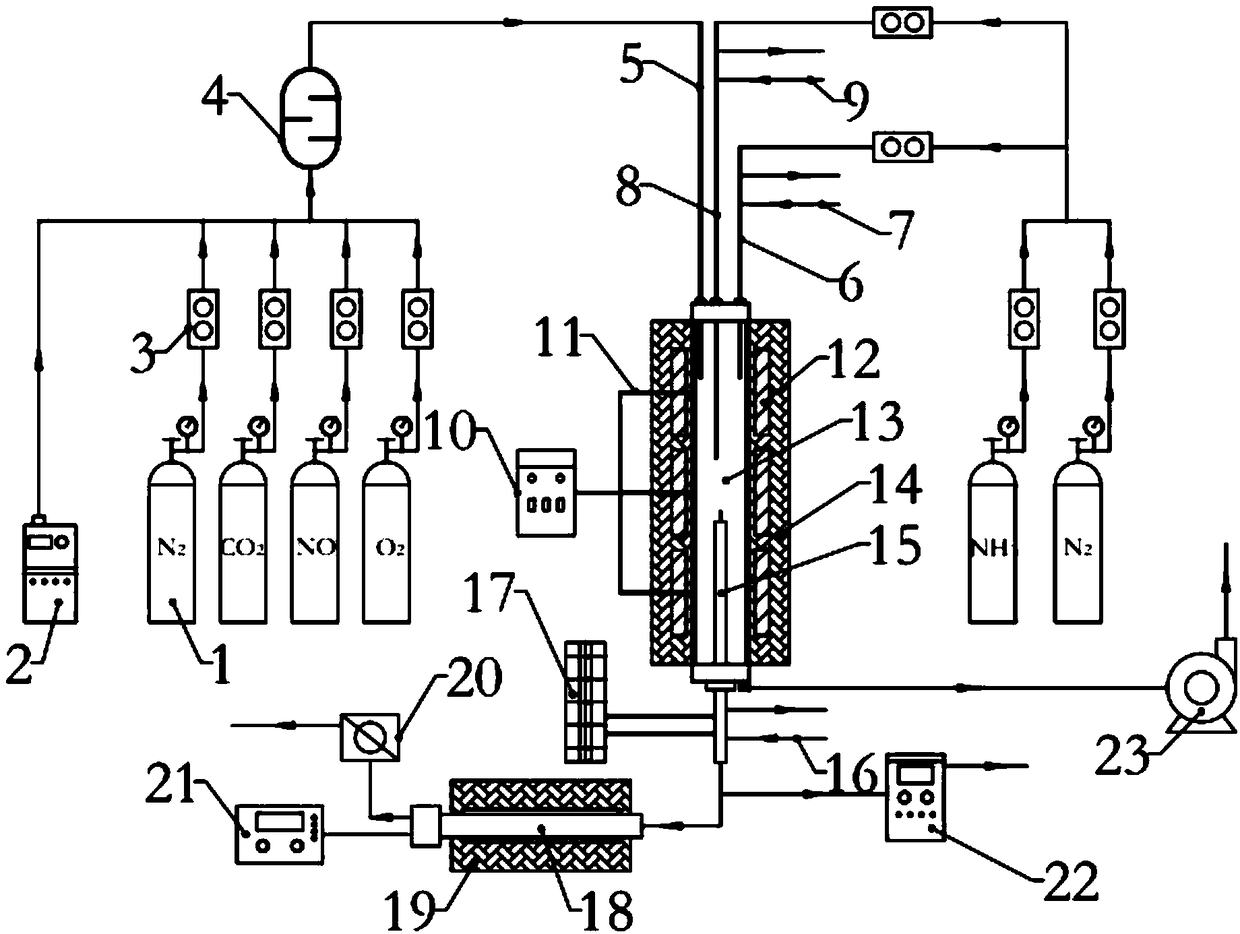

[0033] Such as figure 1 As shown, it mainly includes three parts: gas distribution and intake system, plug flow reactor system and sampling test system.

[0034] The gas distribution and intake system is composed of gas distribution bottle 1, metering steam generator 2, mass flow meter 3, mixed gas preheater 4, mixed gas sampling gun 5, ammonia gas sampling gun 6, ammonia gas sampling gun cooling Water pipeline 7, ammonia replenishing sampling gun 8, and ammonia replenishing sampling gun cooling water pipeline 9; gas distribution cylinder 1 is two groups of gas cylinders, the first group includes nitrogen cylinder, oxygen cylinder, carbon dioxide cylinder and nitrogen monoxide gas cylinder The second group includes nitrogen cylinders and ammonia cylinders; after the nitrogen cylinders, oxygen cylinders, carbon dioxide cylinders and nitric oxide cylinders are decompres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com