Progressive rotational shear feeding method and progressive rotational shearing machine

A rotary shearing, progressive technology, applied in the direction of shearing device, shearing machine equipment, accessories of shearing machine, etc., can solve problems such as deformation of blanks, slump of incisions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

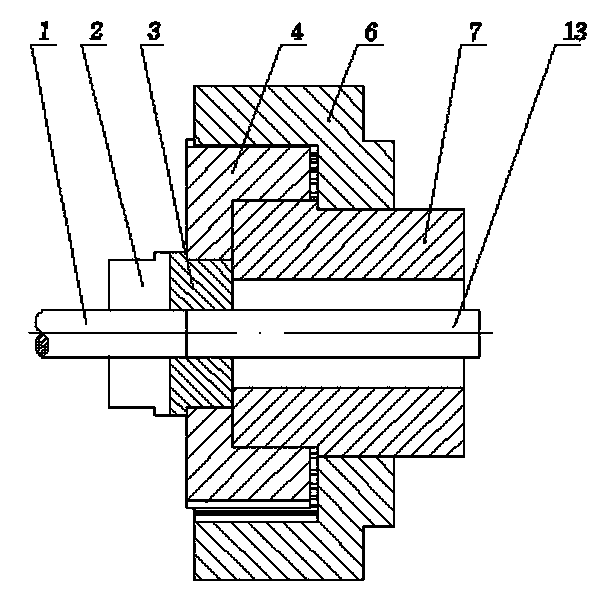

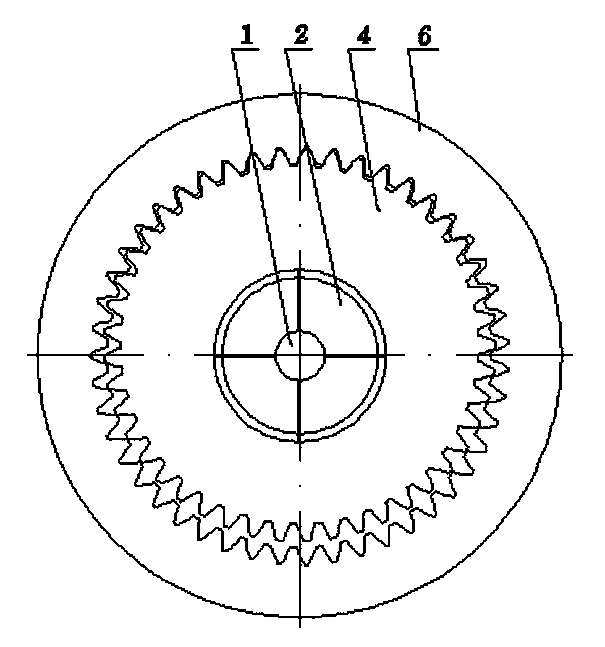

[0041] Such as figure 1 , 2 As shown, the double crankshaft mechanism includes the driving crankshaft, the active internal meshing ring gear sleeved on the concentric end of the driving crankshaft, the internal meshing external gear sleeved on the eccentric end of the driving crankshaft and meshed with the internal meshing ring gear; the movable knife is installed in the eccentric hole of the internal meshing external gear Inside.

[0042] The crankshaft rotates around the axis, and the internal meshing ring gear rotates around the axis. When there is a speed difference between the two rotation speeds, the moving knife performs a constant speed helical motion.

Embodiment 2

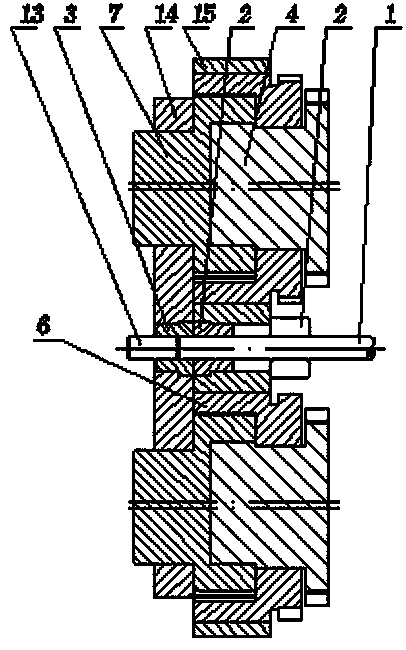

[0044] This embodiment is a modified structure of Embodiment 1, and the double crankshaft mechanism is set as two sets, and the moving knife plate structure is added. Such as image 3 , 4 shown. The double crankshaft mechanism includes two driving crankshafts, two internal meshing ring gears sleeved on the concentric end of the driving crankshaft, two internal meshing external gears sleeved on the eccentric end of the driving crankshaft and meshed with the internal meshing ring gear; two sets of driving crankshafts, driving internal meshing gears The ring and the inner meshing outer gear are symmetrical to the axis center of the moving knife; the moving knife plate is installed on the two inner meshing outer gears, and the moving knife is installed in the middle of the moving knife plate.

[0045] The two crankshafts rotate at the same speed, and the two internal meshing ring gears rotate at the same speed. When there is a speed difference between the two rotation speeds, th...

Embodiment 3

[0048] Such as Figure 5 , 6 As shown, the double crankshaft mechanism includes a driving crankshaft and an eccentric shaft sleeved on the driving crankshaft; the moving knife is installed in the shaft hole of the eccentric shaft.

[0049] The active crankshaft rotates around the axis, and the eccentric shaft rotates around the axis. When there is a speed difference between the two rotation speeds, the moving knife performs a constant-speed spiral motion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com