Mud water balance shield tunnelling machine and pipe jacking tunnelling construction method by applying mud water balance shield tunnelling machine

A mud-water balance and shield machine technology, which is applied in basic structure engineering, earthwork drilling, soil protection and other directions, can solve the problems of difficulty in ensuring the safety of construction workers, cutting of large-diameter pebble strata, large stratum settlement and deformation, etc. Efficient construction, preventing pavement settlement and deformation, and improving the effect of fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

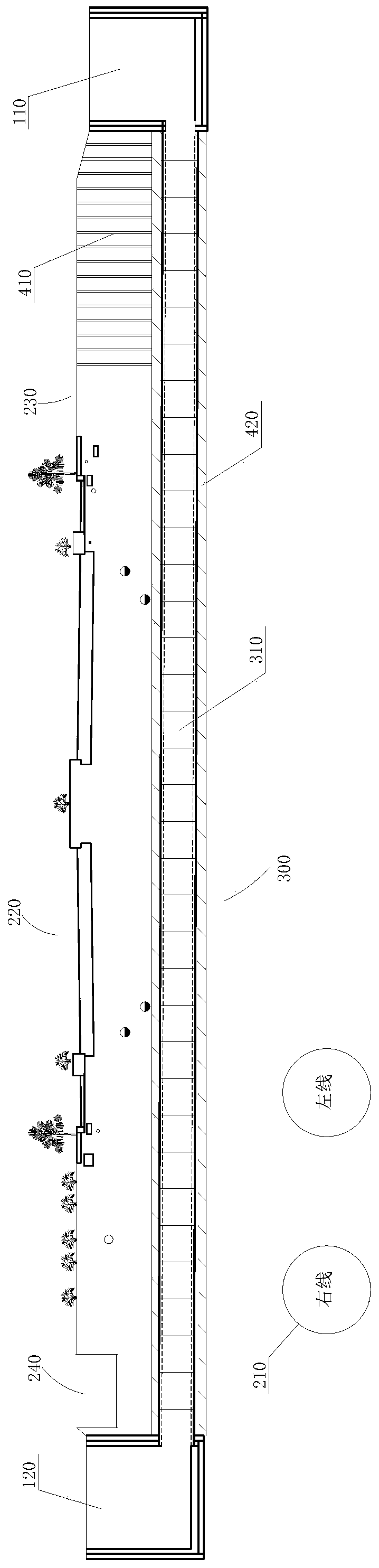

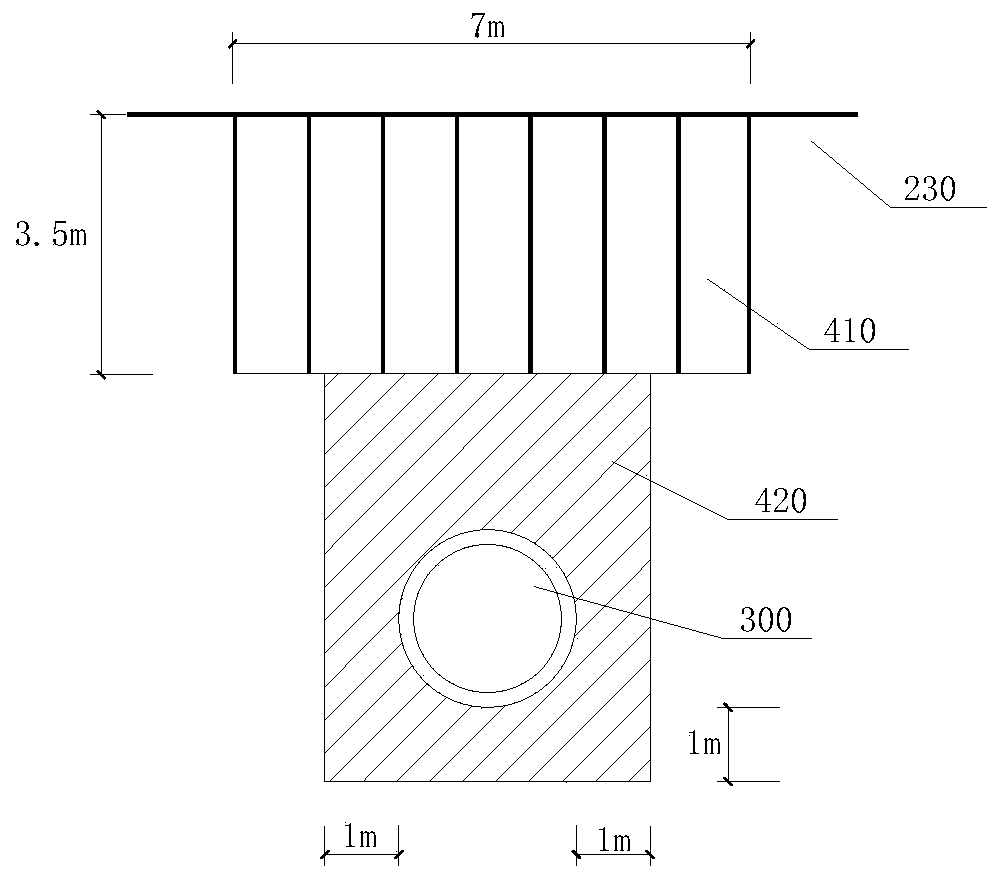

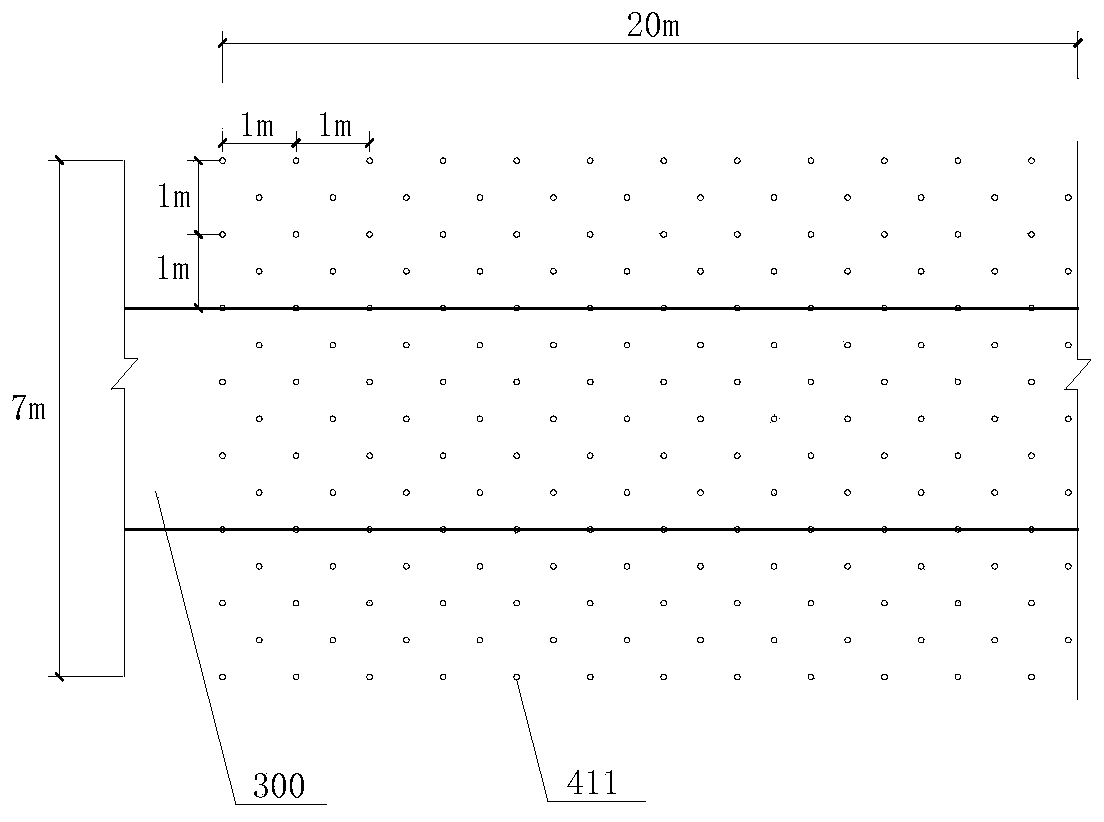

[0062] Such as figure 1 The power channel structure across the subway line shown includes the originating shaft 110, the receiving shaft 120, the pipe jacking section 300 connecting the originating shaft 110 and the receiving shaft 120, and the reinforcement structure, and the pipe jacking section 300 includes concrete pipes connected end to end Section 310.

[0063] The originating shaft 110 and the receiving shaft 120 are respectively located on both sides of the existing subway line 210, and the distance between the originating shaft 110 and the existing subway line 210 is greater than the distance between the receiving shaft 120 and the existing subway line 210; The road between the receiving shaft 120 and the originating shaft 110 includes the existing road 220 and the undisturbed soil 230 on both sides of the existing road 220; the cross section of the originating shaft 110 is a rectangle; the cross section of the receiving shaft 120 is a circle shape.

[0064] The bur...

Embodiment 2

[0070] Such as Figure 5-7 The mud-water balance shield machine shown includes a rotatable cutter head 500, a cutting mechanism, a twisting leg 540, a disc body 800, a first grouting mechanism, a second grouting mechanism and a third grouting mechanism, the disc body 800 and the third grouting mechanism A crushing bin 550 is formed between the cutter heads 500, and a muddy water bin 830 is formed behind the disc body 800.

[0071] Such as Figure 5 As shown, the cutterhead 500 has a tapered surface 510 with a gradually decreasing cross-section and a propulsion surface 520 matched with the palm surface. The propulsion surface 520 is provided with a feed port 530, and the opening ratio of the cutterhead 500 is 29%. There are four feed ports 530 and they are distributed symmetrically with the center of the propulsion surface 520; the feed ports 530 extend to the end of the conical surface 510; gradually increase;

[0072] The cutting mechanism includes a first cutting assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com