TBM hobbing cutter stress online real-time monitoring apparatus and monitoring method

A real-time monitoring, hob technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., to solve problems such as unequal forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

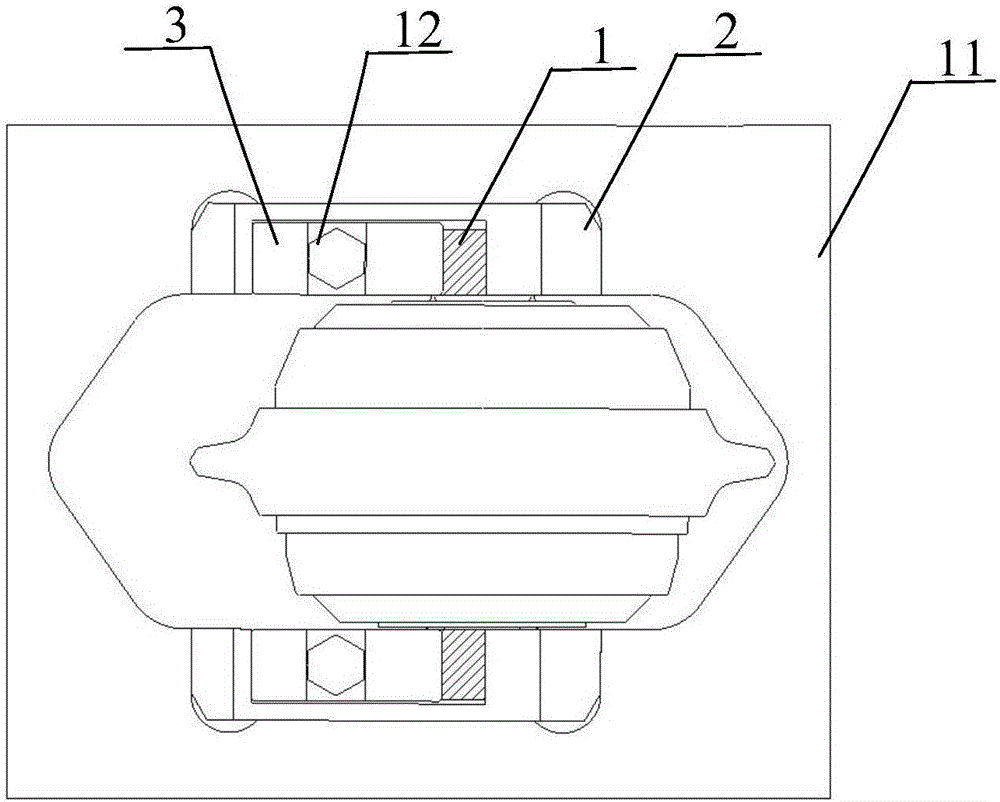

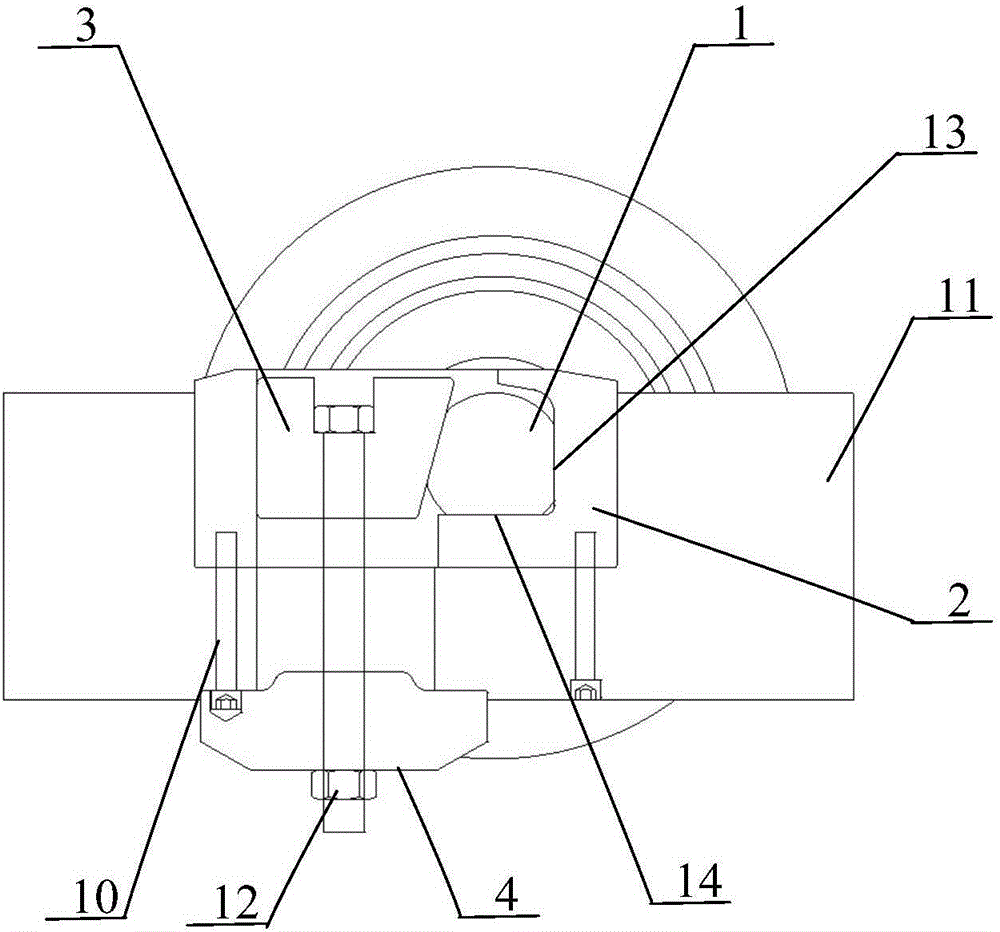

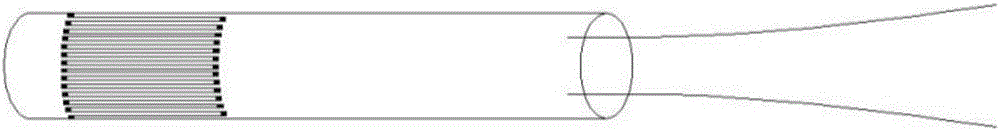

[0035]The online real-time monitoring device for TBM hob force shown in the figure includes support pad 2, upper pressing block 3, lower pressing block 4, strain gauge 5, strain gauge 6, wireless transmitting module 7, wireless receiving module 8 And monitoring computer 9, described support cushion block 2 is fixed on the knife case 11 by small bolt 10, and upper pressing block 3 is fixed on the knife box 11 by large bolt 12, and support cushion block 2 is provided with two, is used for supporting At both ends of the cutter shaft 1, the upper pressing block 3 is used to compress the cutter shaft 1 so that no displacement occurs between the cutter shaft 1 and the support pad 2, and the strain gauge 5 is installed in the support pad 2 to obtain the support pad Block strain data, strain gauge 5 is connected with strain gauge 6 by wire, and wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com