Hobbing cutter abrasion test experimental platform and matched measurement evaluation method

A technology for testing experiments and evaluation methods, applied in the field of experimental platforms, can solve the problems of lagging measurement results, weak engineering guidance, large measurement errors, etc., and achieve the effects of simple structure, convenient operation, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

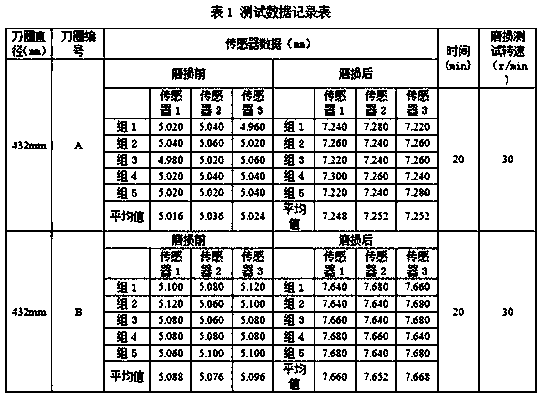

Examples

Embodiment 1

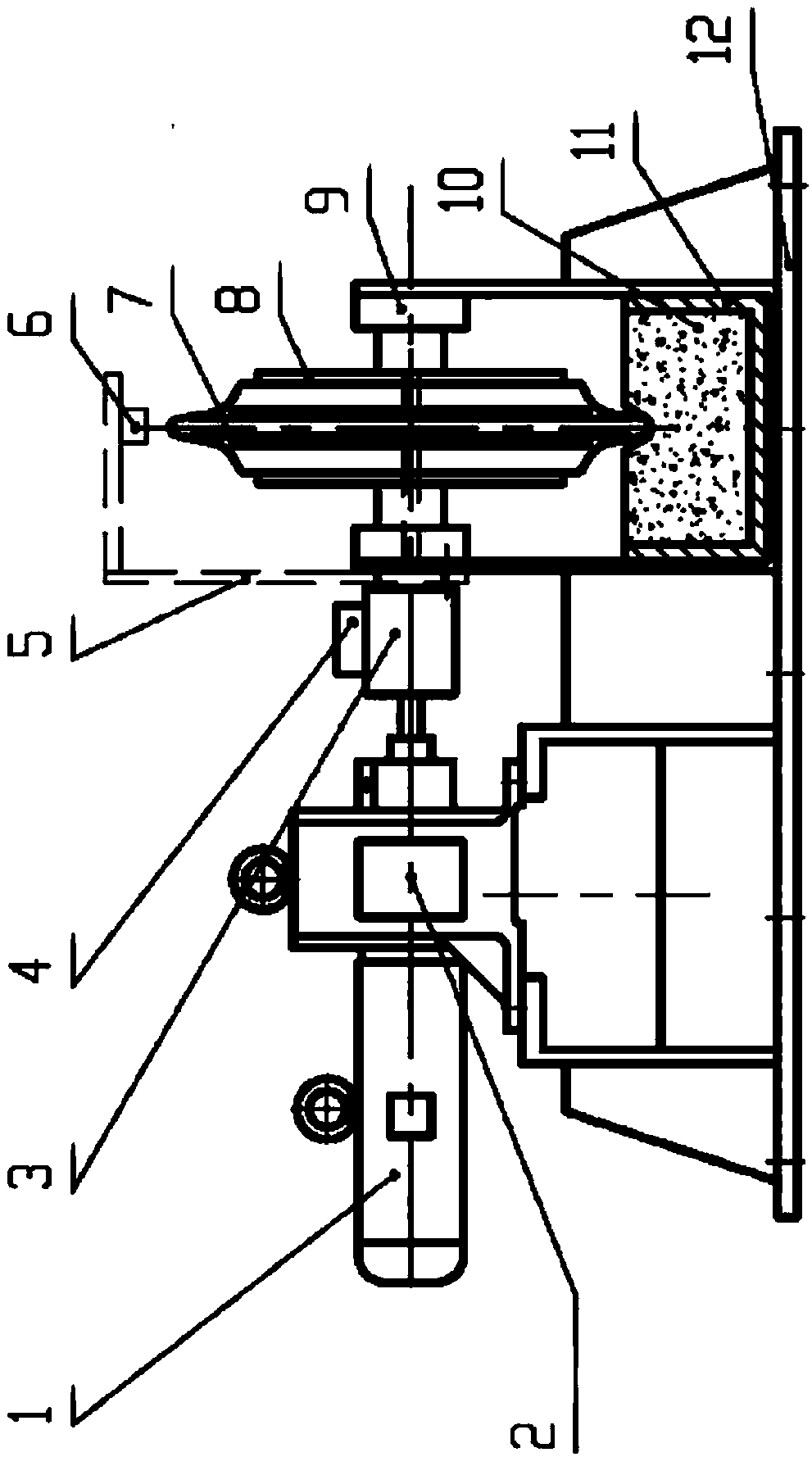

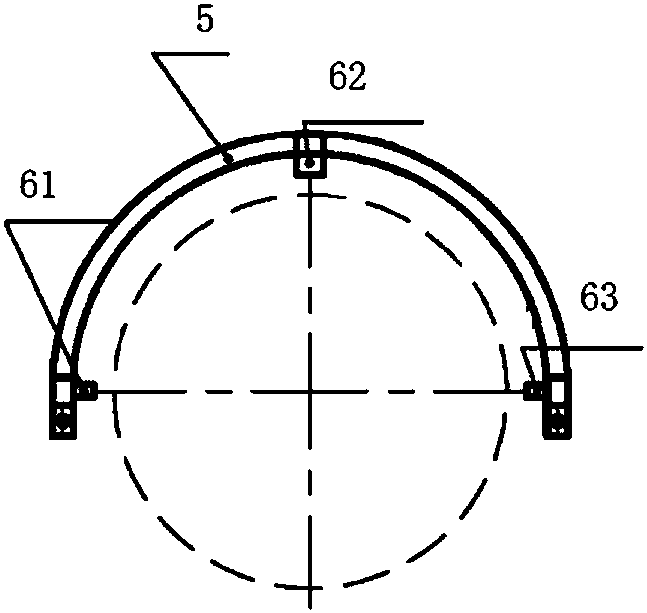

[0030] A hob wear test platform, see Figure 1 to Figure 2 , the platform is equipped with an abrasive box 11 and a transmission device, and the output end of the transmission device is equipped with a clamping element for clamping the hob cutter ring 7, so that the hob cutter ring 7 is above the abrasive box 11; the clamping element includes two sides Cutter shaft support 9, one side is fixed on the output end of the transmission, and the other side is fixed on the abrasive box 11, the outer ring of the cutter hub 8 matches the hob cutter ring 7, and the inner ring of the cutter hub 8 matches the cutter The shaft support 9 cooperates; a sensor bracket 5 is also installed on the transmission device, and an eddy current sensor element is installed on the sensor bracket 5 and corresponding to the outer side of the hob cutter ring 7 .

[0031] The transmission device includes a reducer 2 and a coupling 3 installed at the output end of the motor. One end of the coupling 3 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com