Shield machine roller cutter back mounting type self-positioning fixing device

A fixing device and self-positioning technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as loose connecting bolts, narrow tool operating space, and large vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

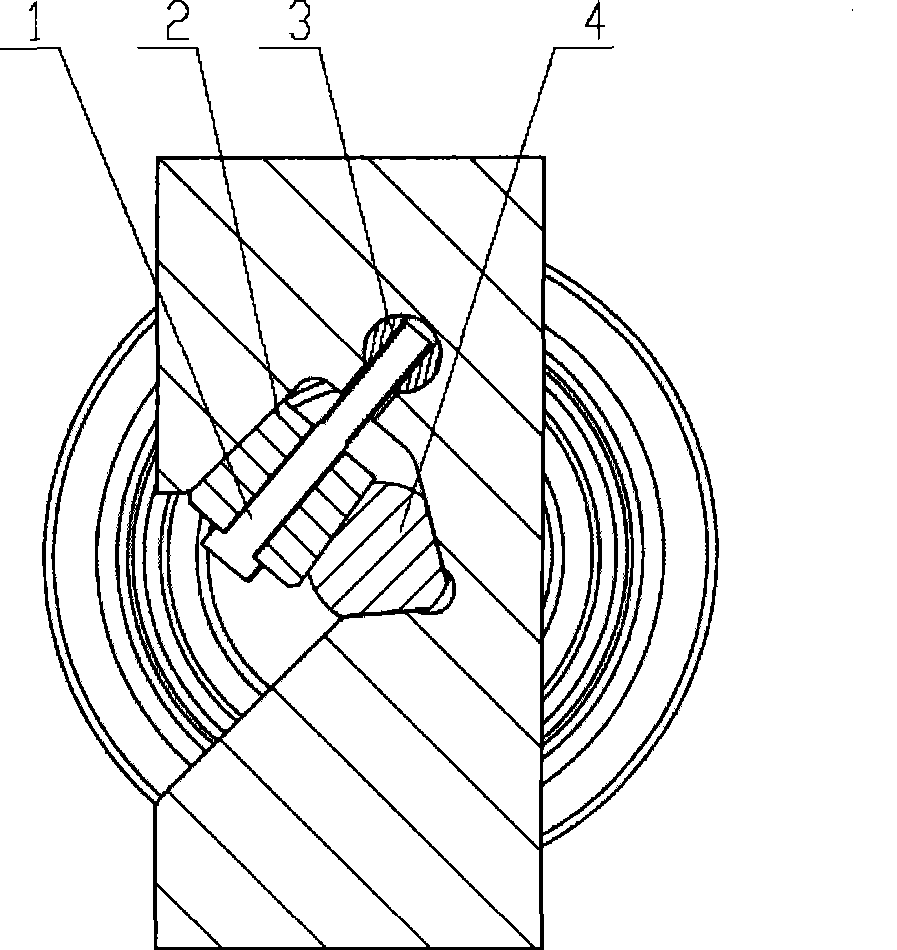

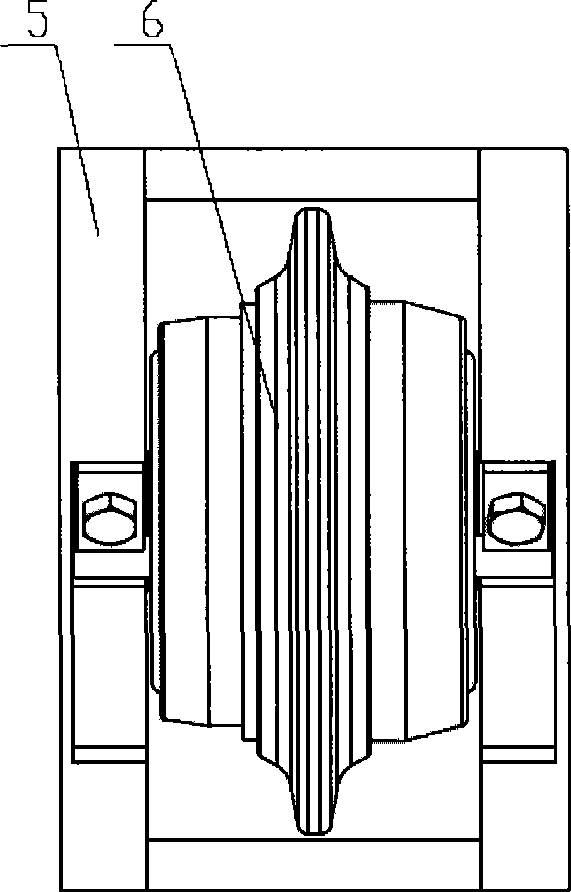

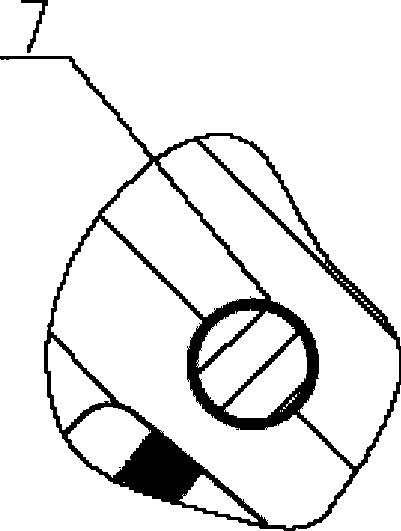

[0013] Referring to the accompanying drawings, the back-mounted self-positioning and fixing device for the hob of the shield machine is composed of a bolt 1, a wedge-shaped pressing block 2, a special-shaped nut 3, a hob shaft 4, a knife seat 5, a hob 6, and an O-ring 7 The special-shaped nut 3 is used together with the O-shaped sealing ring 7, and the hob shaft 4 is made to match the shape of the fixed part of the hob shaft 4 on the side panel of the knife seat 5, and is in contact with the side panel of the knife seat 5 through two planes Positioning, the third plane at the end of the hob shaft 4 is in contact with the side of the wedge-shaped pressing block 2, and the wedge-shaped pressing block 2 installs the hob 6 on the hob shaft during the process of tightening the opposite sex nut 3 through the bolt 1 4 is pressed and fixed on the side panel of the tool holder 5, and the automatic and accurate positioning of the installation is realized at the same time during this proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com