Novel shear crusher and application thereof

A crusher and shearing technology, which is applied in the field of new shearing crushers, can solve the problems of large power consumption, high powder degree, and high powder degree of soybean meal products, and achieve easy operation and maintenance, uniform crushing particle size, and social benefits. Considerable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

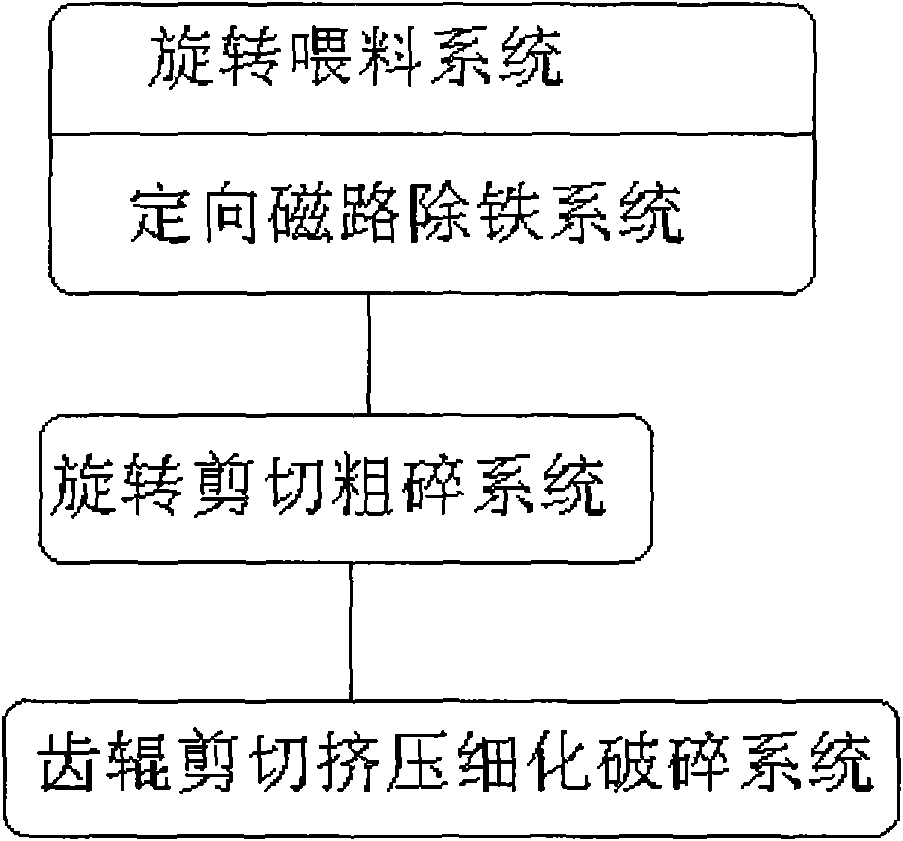

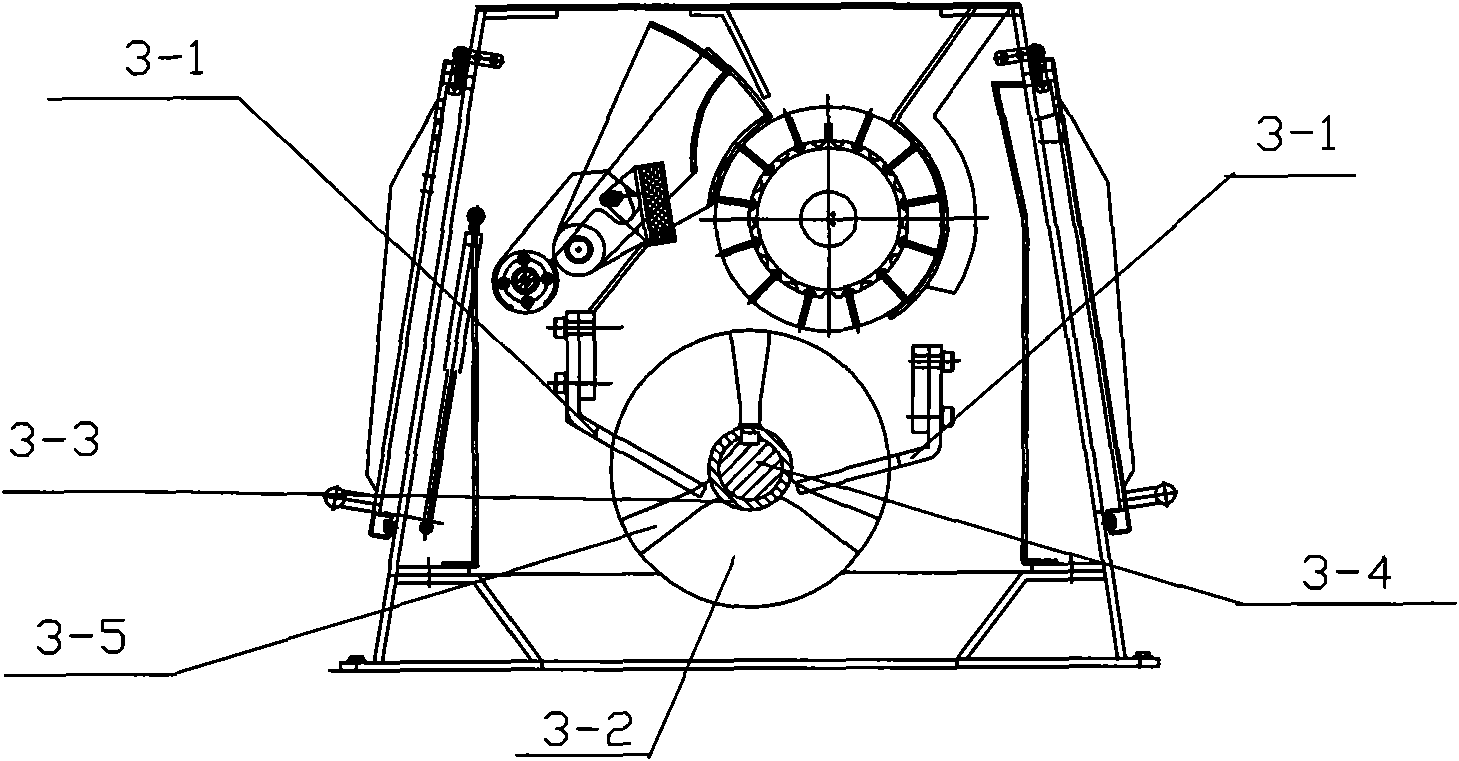

[0027] Such as figure 1 As shown, the present invention is a novel shearing crusher, which is composed of a rotary feeding system, a directional magnetic circuit iron removal system, a rotary shearing coarse crushing system and a toothed roller shearing extrusion refining crushing system; The rotary feeding system is fixedly equipped with a directional magnetic circuit iron removal system, and the downstream of the rotary feeding system is connected with a rotary shearing and coarse crushing system, and the downstream of the rotary shearing and coarse crushing system is connected with toothed rollers, shearing, extrusion and refining broken system.

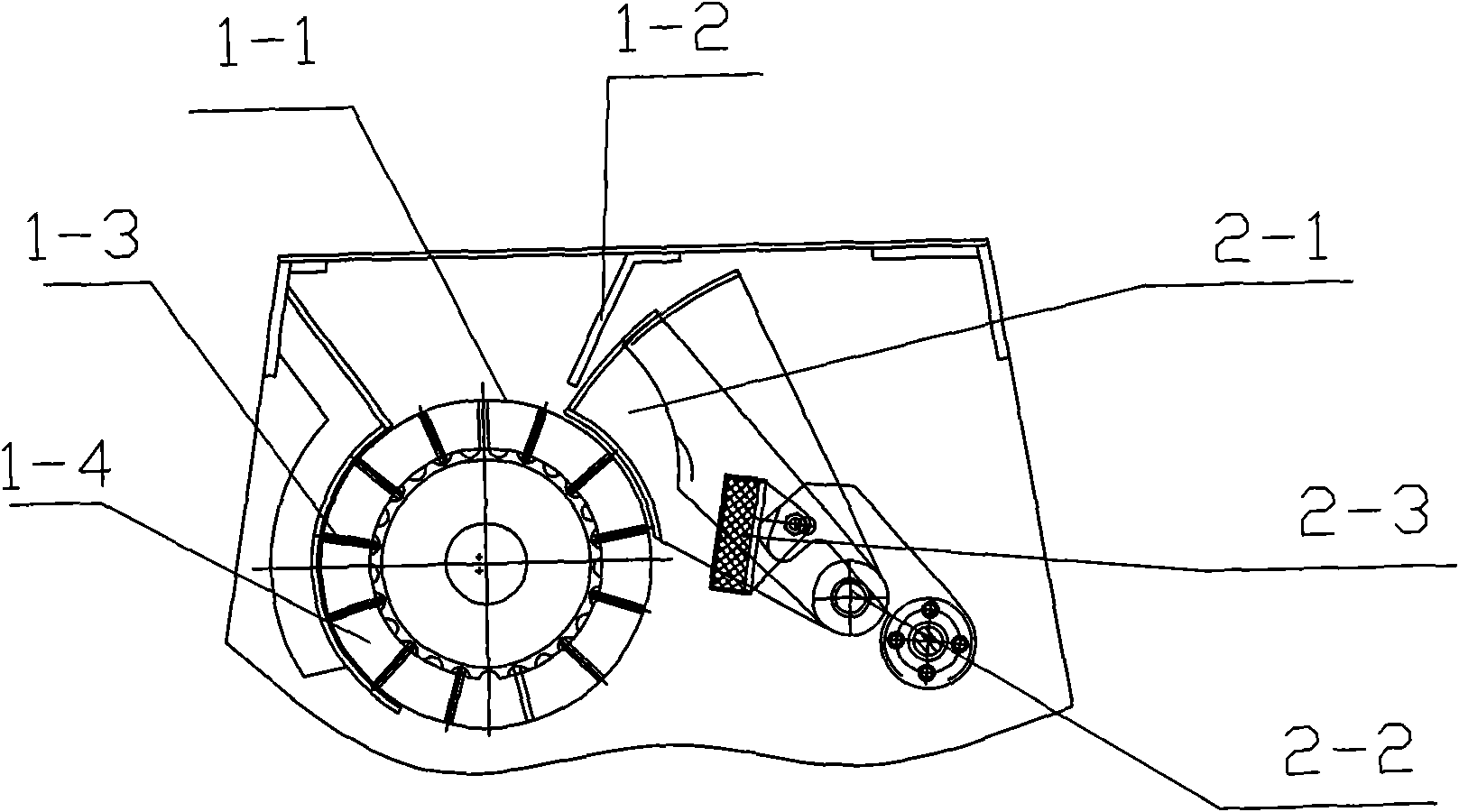

[0028] Such as figure 2 As shown, the rotary feeding system includes a feeding roller 1-1 and a feeding trough 1-2, and the feeding roller is connected to a frequency conversion motor; the feeding trough is fixedly installed above the feeding roller, and the The feeding roller is an open roller, and the roller is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com