Test device and test method for asphalt rotational shear creep and repeated creep recovery

A rotational shearing and creep recovery technology, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, which can solve the problems of lack of application, limited scope of application, and high difficulty in modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment and test method of the present invention will be described in detail below in conjunction with the accompanying drawings.

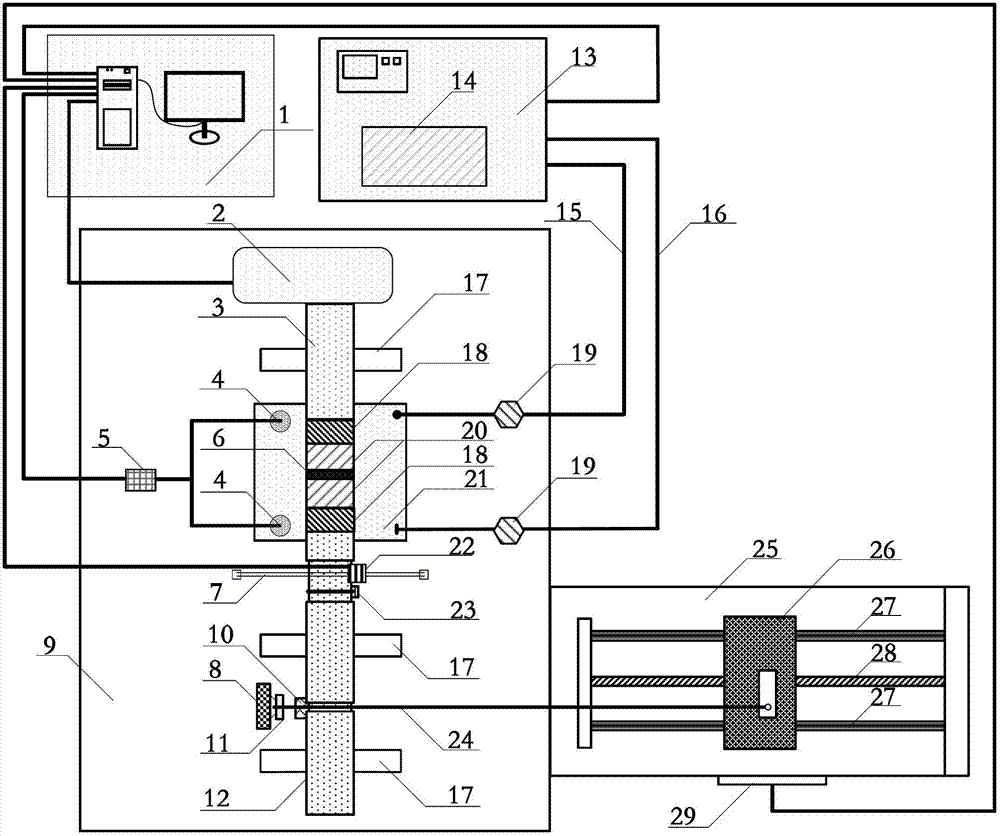

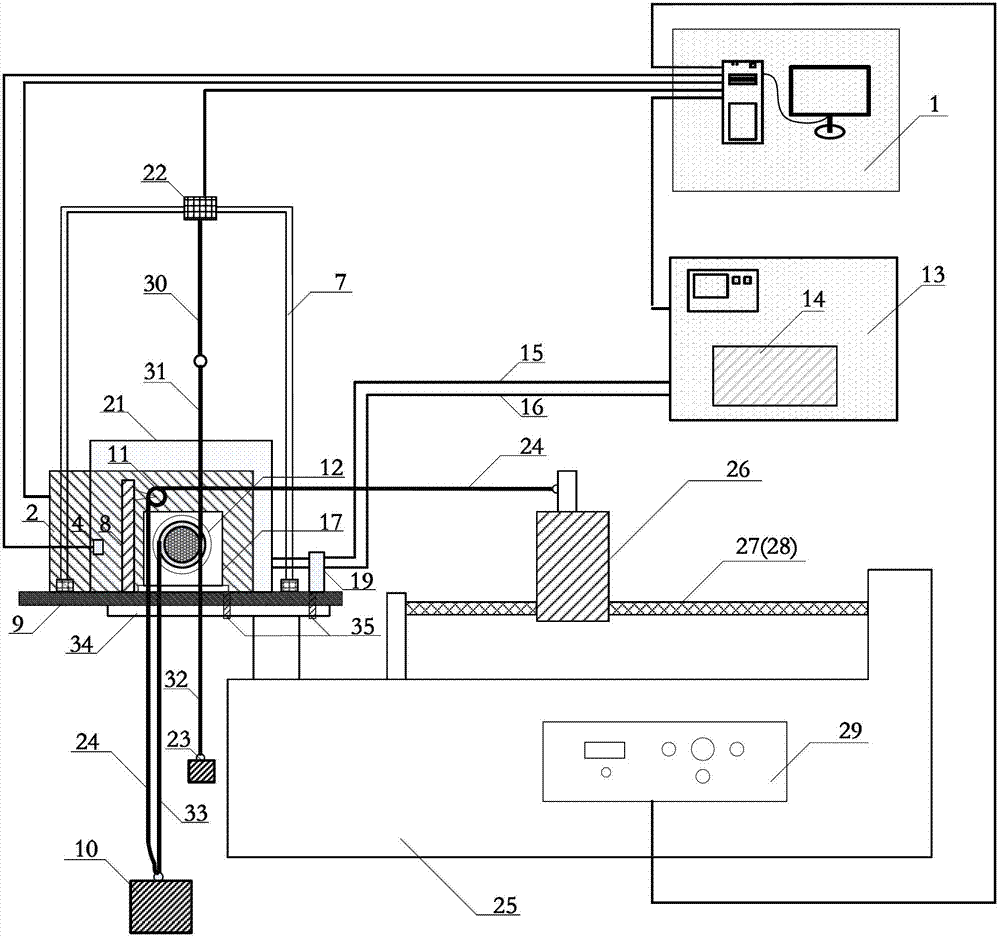

[0016] Asphalt rotary shear creep and repeated creep recovery test device is composed of test platform 9, test specimen, temperature control system, loading system and computer control system; the computer control system controls the curing temperature, creep The variable test temperature is automatically controlled; at the same time, the computer control system also controls the loading system to complete the rotational shear creep and repeated creep recovery tests of asphalt specimens.

[0017] The test platform 9 is composed of a basic steel plate, a bearing seat 17, a fixed shaft 3, a rotating shaft 12, a test specimen, a torque sensor and an encoder 2, a pull-wire displacement sensor and an encoder 22, and a balance weight 23; three bearing seats 17 are arranged side by side Fixed on the test platform 9, one of the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com