Control method and control system of tension in the process of rolling periodic variable-thickness strips

A strip rolling and control method technology, applied in tension/pressure control, rolling mill control device, metal rolling, etc., can solve problems such as inability to meet tension control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

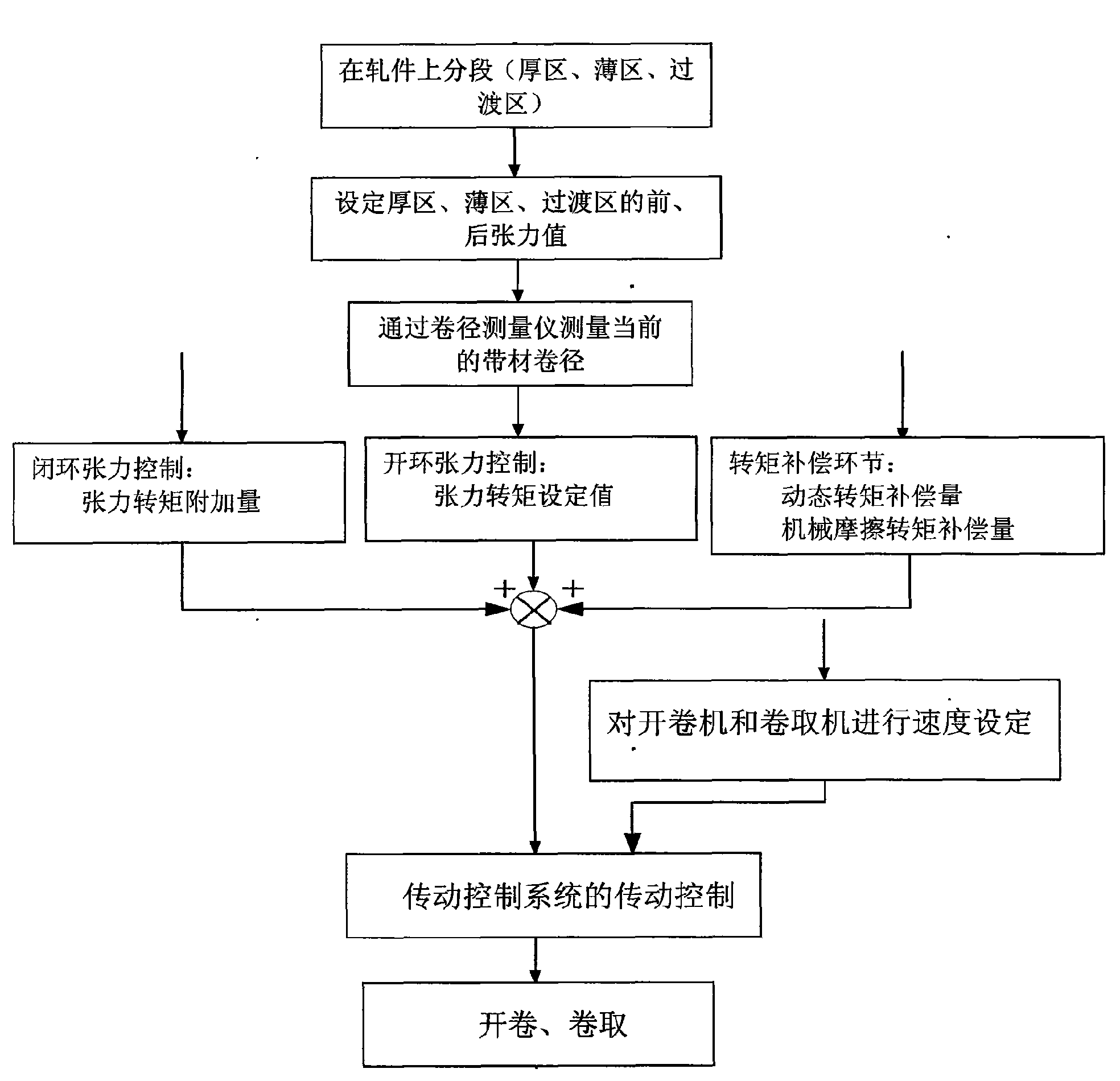

Method used

Image

Examples

Embodiment 1

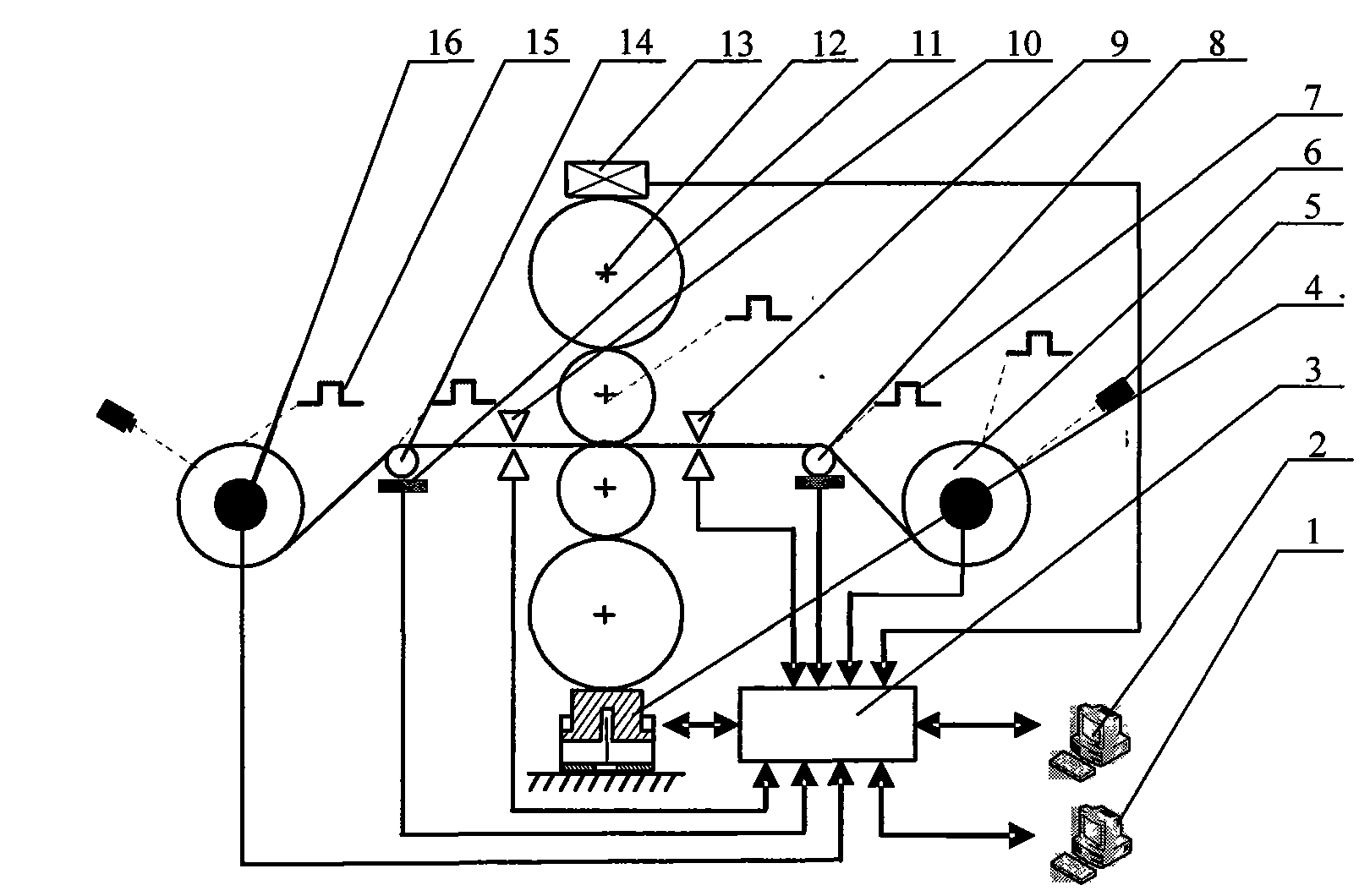

[0125] The relevant parameters of the system of the present invention are as follows:

[0126] A 650mm four-high reversible rolling mill is used, and the distance between the two tension gauges and the center line of the rolling mill is 2000mm; the measuring range of the coil diameter measuring instrument is 500-1600mm, and the resolution is 0.1mm; the measuring range of the tensiometer is 0-300kN. The accuracy indicators are as follows:

[0127] Response time: less than 0.01ms;

[0128] Non-repeatability: less than ±0.05% of rated output;

[0129] Hysteresis: Less than ±0.10% of rated output;

[0130] Non-linearity: Less than ±0.25% of rated output;

[0131] Temperature bias: less than ±0.005% of full scale / ℃;

[0132] Temperature: Temperature compensated to 100°C with a maximum operating temperature of 150°C.

[0133] Incoming material status: uniform thickness, steel type is IF, width 500mm, thickness 1.3mm;

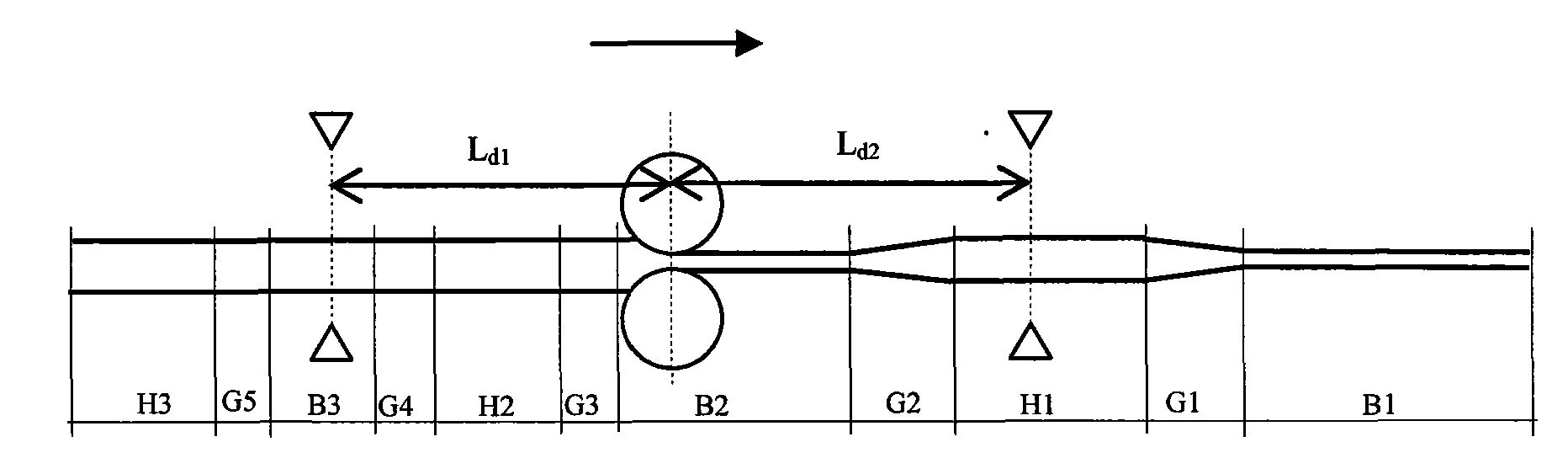

[0134] Product size: thick zone thickness 1.2mm, length 30...

Embodiment 2

[0139] The relevant parameters of the system of the present invention are as follows:

[0140] A 650mm four-high reversible rolling mill is used, and the distance between the two tension gauges and the center line of the rolling mill is 2000mm; the measuring range of the coil diameter measuring instrument is 500-1600mm, and the resolution is 0.1mm; the measuring range of the tensiometer is 0-300kN. The accuracy indicators are as follows:

[0141] Response time: less than 0.01ms;

[0142] Non-repeatability: less than ±0.05% of rated output;

[0143] Hysteresis: Less than ±0.10% of rated output;

[0144] Non-linearity: Less than ±0.25% of rated output;

[0145] Temperature bias: less than ±0.005% of full scale / ℃;

[0146] Temperature: Temperature compensated to 100°C with a maximum operating temperature of 150°C.

[0147] Incoming material status: Uniform thickness, steel type is ST12, width 450mm, thickness 2mm;

[0148] Product size: thick zone thickness 1.5mm, length 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com