Flexible general production line and production method of electronic product

A flexible production line and electronic product technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as cost increase and waste, increase product qualification rate, prevent external interference, assembly and testing The effect of compact and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

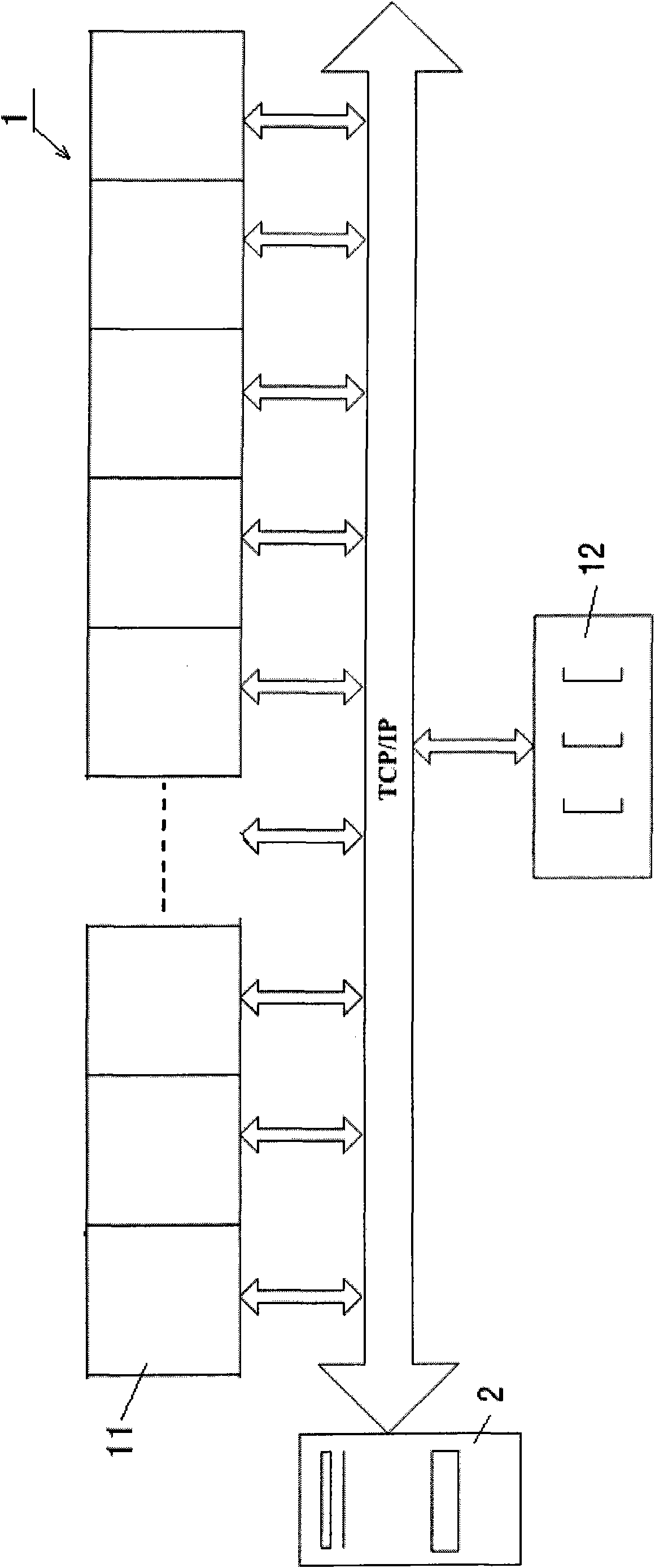

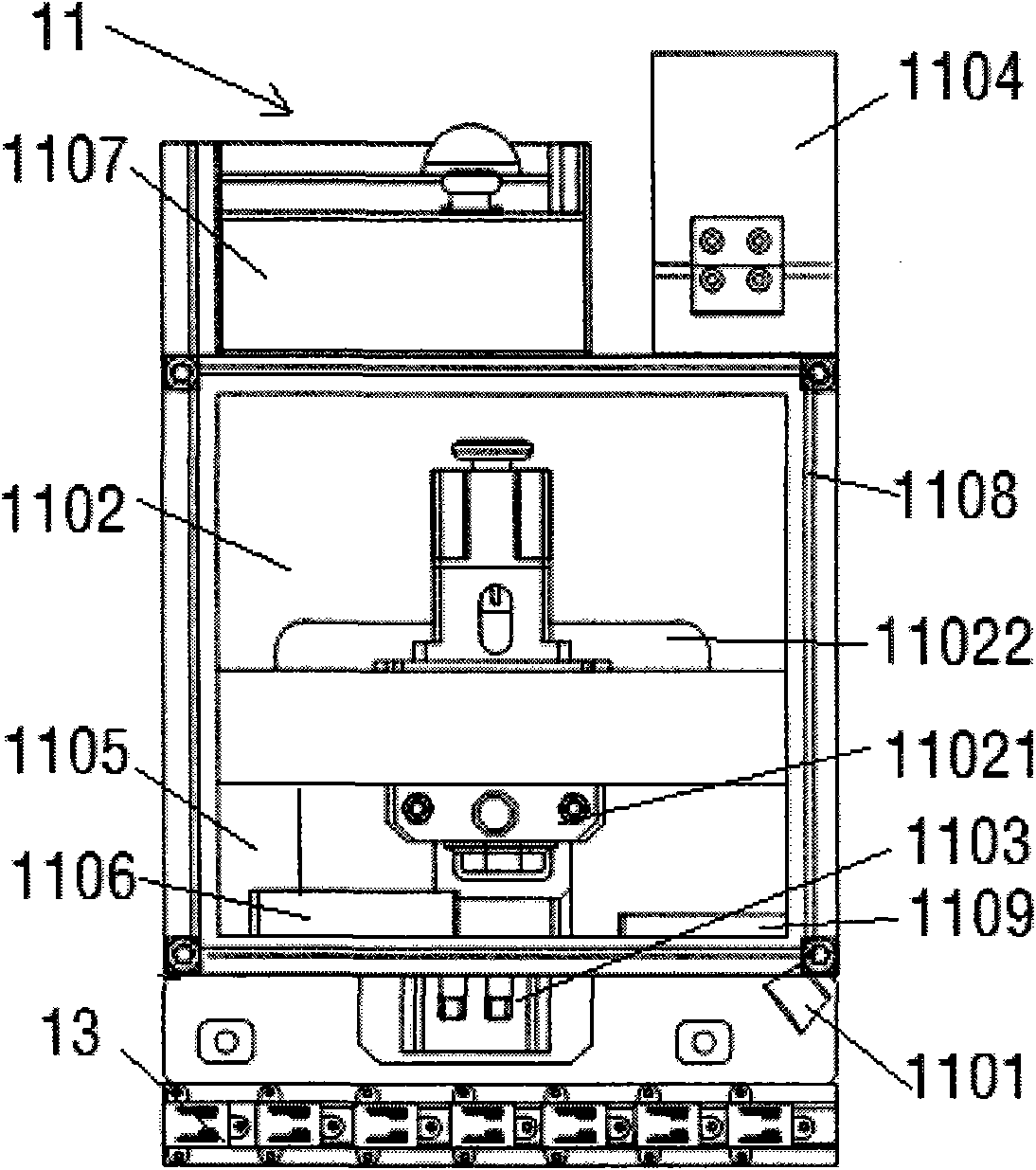

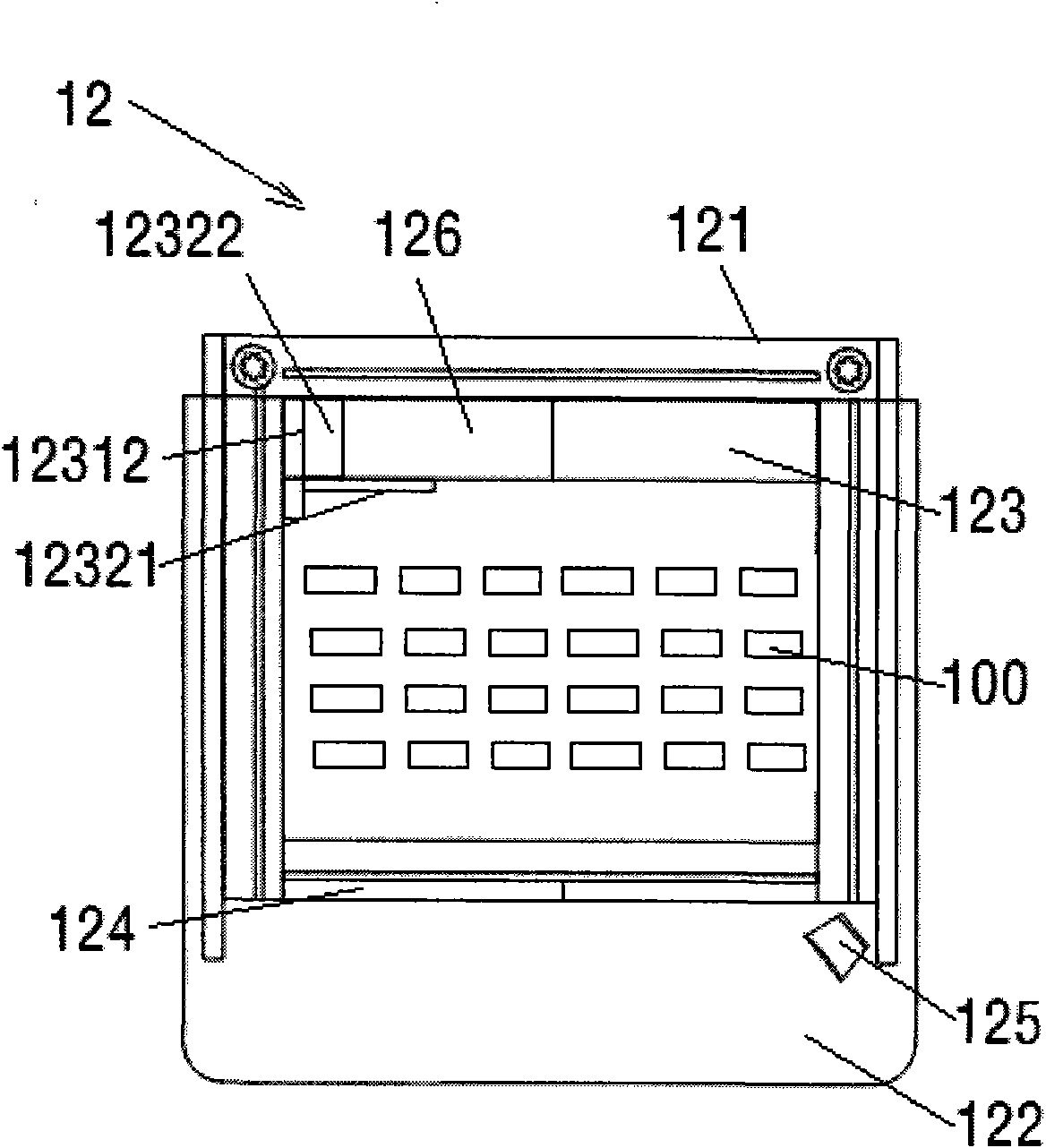

[0045] The present invention is a flexible general-purpose production line for electronic products. According to the performance requirements of the produced electronic products, a plurality of independent functional module platforms with the same structure but different functions, which can be moved and combined, and at least one high-temperature The aging stations are arranged together to form a general production line suitable for the production of electronic products, and the intelligent control system of the flexible production line realizes the flexible intelligent control of the whole process of the products produced.

[0046] see figure 1 , figure 1 It is a schematic diagram of an embodiment of a flexible electronic product universal production line and information interaction in the present invention. This production line is used for testing and assembly of electronic products. The production line includes: the mainstream production line 1 for producing ballast prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com