Arc hedgerow cutter

A hedge and arc technology, which is applied to the equipment for trimming hedges and other directions, can solve the problems of difficult pruning quality, difficult pruning, and low work efficiency, and achieve the effect of improving pruning efficiency, good pruning effect and rapid pruning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

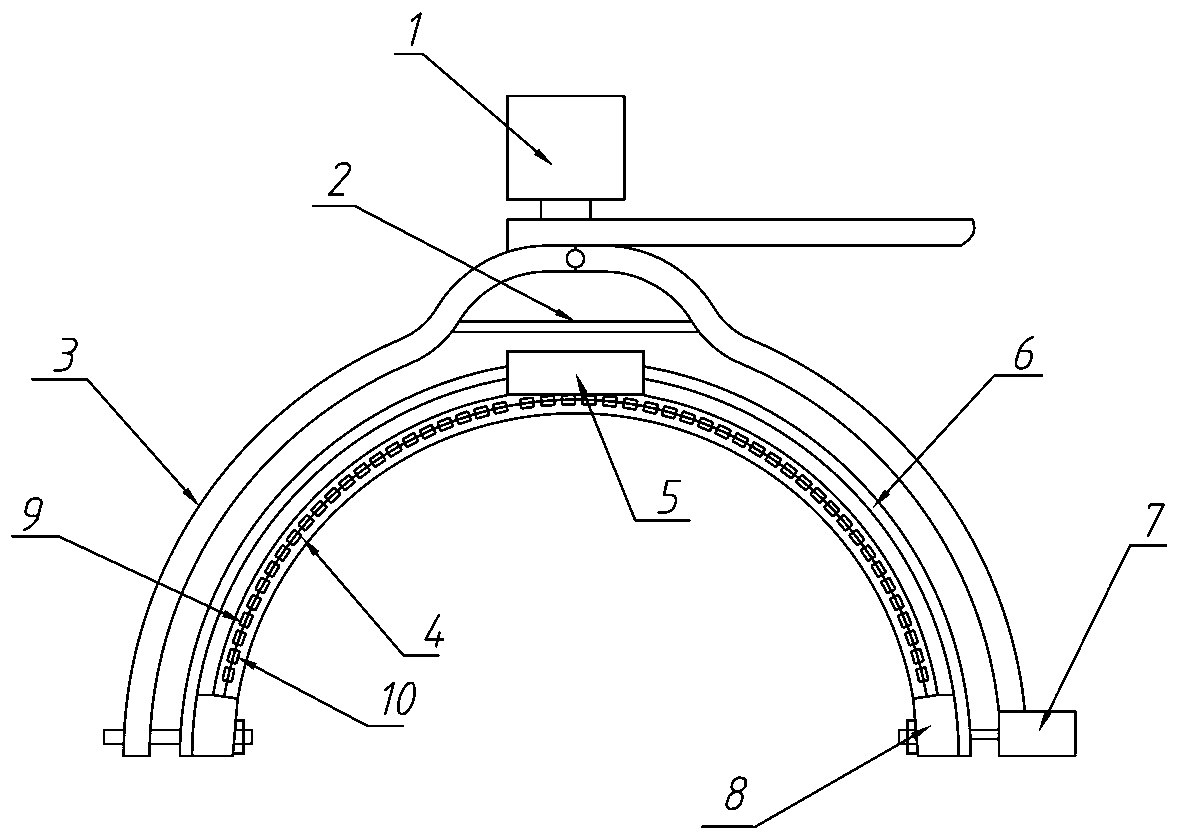

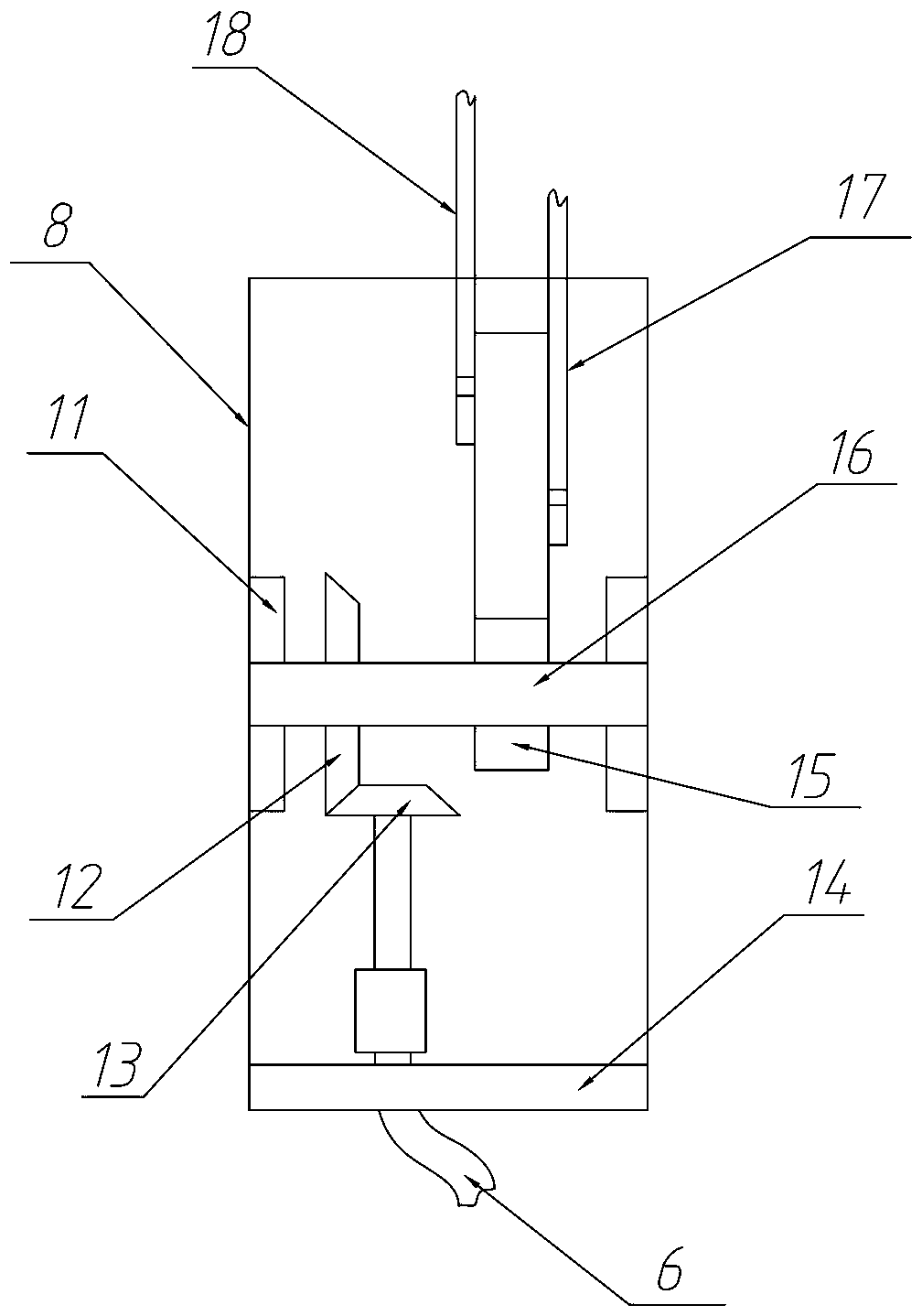

[0023] The arc hedge knife of the present invention comprises a shearing knife body 4 and two arc-shaped knife rests 3, and the two arc-shaped knife rests 3 are rotated and connected to form a semicircular knife rest, and the two ends of the semicircular knife rest are respectively Rotately connected with the two ends of the shearing knife body 4, a through-axis motor 5 is arranged on the semicircular knife holder, and the two output ends of the through-axis motor 5 are connected to the flexible shaft 6 and the connection of the shearing knife body 4 respectively. The two ends are connected; a vertical rotating motor 7 is also arranged on the semicircular knife rest, and a speed reducer is connected on the vertical rotating motor 7, and the speed reducer is connected to one end of the shearing cutter body 4 by the gears meshing with each other. Connected, the vertical rotation motor 7 drives the gear to rotate, and drives the shearing knife body 4 to rotate in the vertical plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com