System and process for formation of extrusion structures

a technology of extrusion structure and process, which is applied in the direction of metal extrusion, manufacturing tools, extrusion control devices, etc., can solve the problems of insufficient cost-effectiveness of commercial production processes, inconvenient processing of extrudates, and inability to meet the requirements of extrusion requirements, etc., to achieve the effect of improving mechanical properties, resisting bending, and improving performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]A new shear-assisted extrusion apparatus and process are disclosed for producing high-performance extrusion structures including, e.g., hollow and solid extrusion structures. In the following description, embodiments of the present invention are shown and described that include a best mode contemplated for carrying out the invention. It will be clear from the following description that the invention is susceptible of various modifications and alternative constructions. The present invention is intended to cover all modifications, alternative constructions, and equivalents falling within the spirit and scope of the invention as defined in the claims. Therefore the description should be seen as illustrative and not limiting.

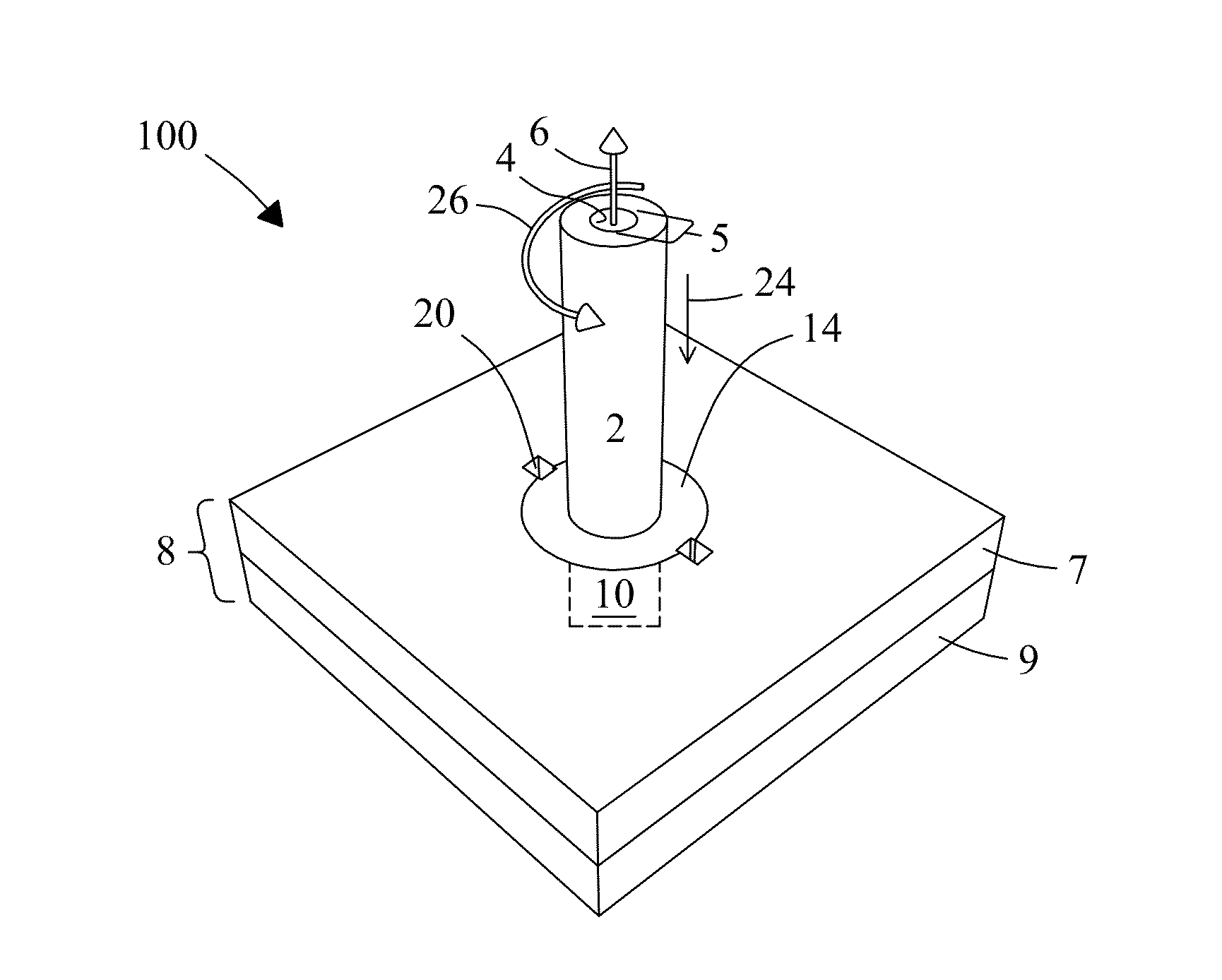

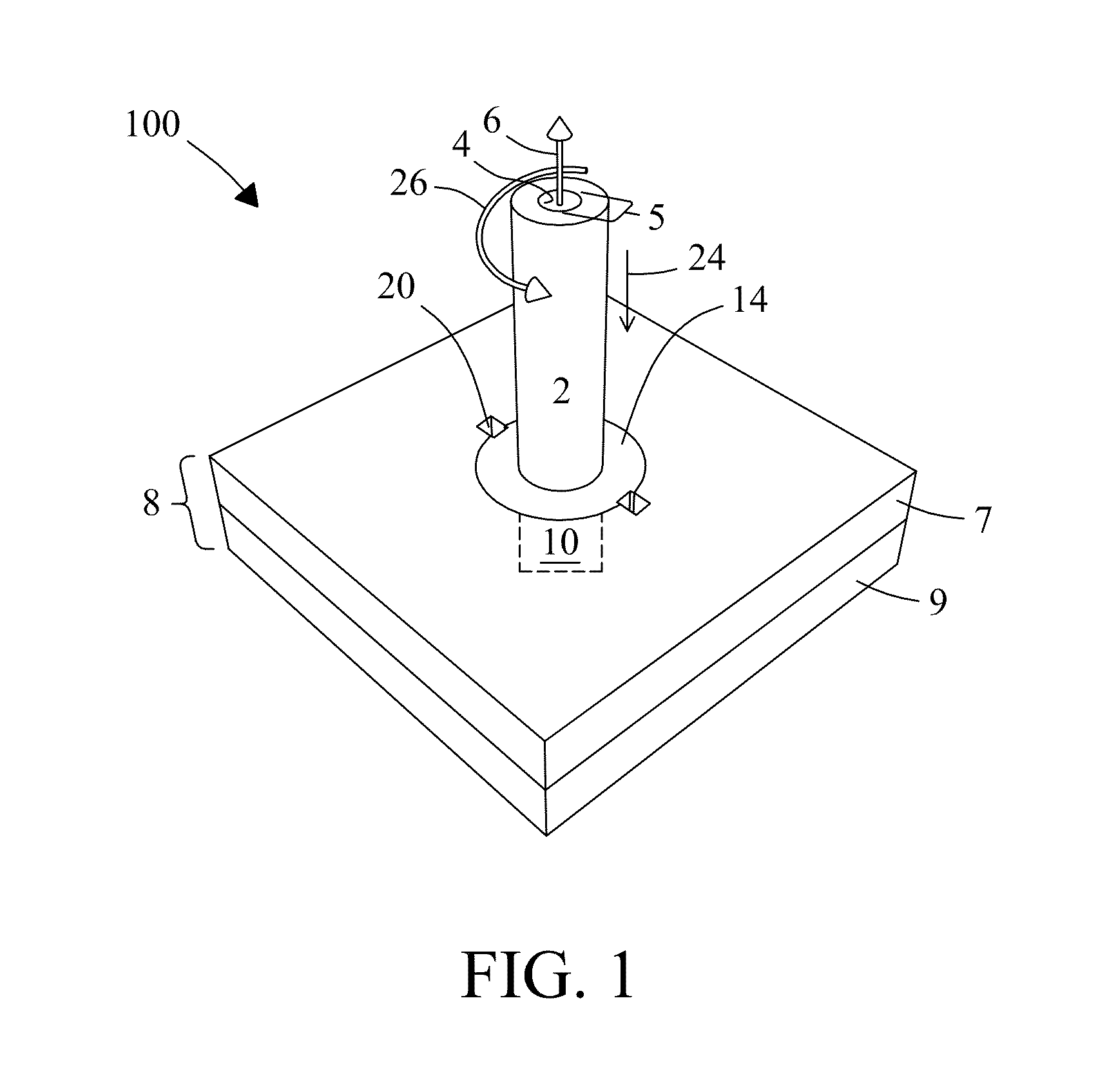

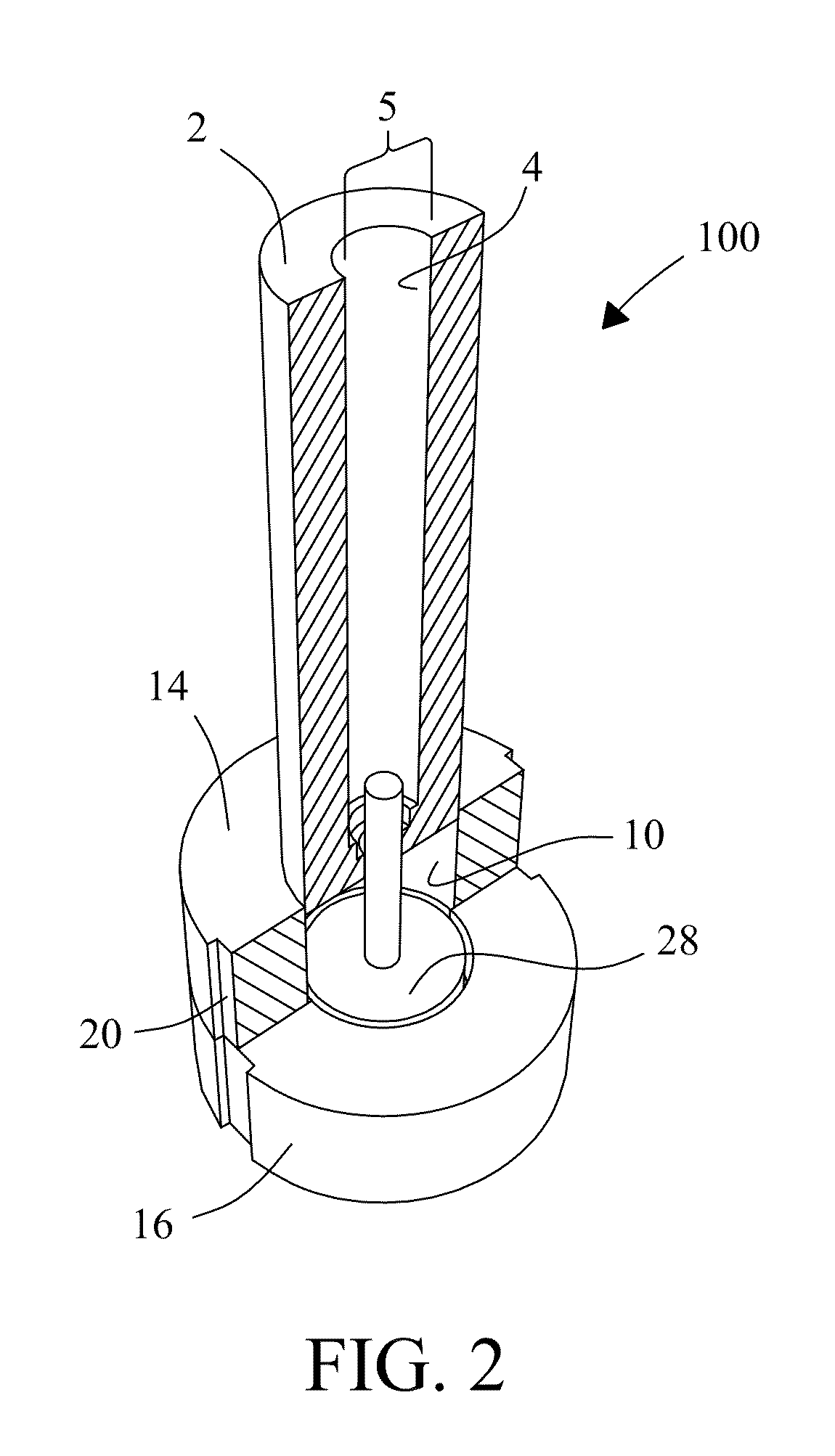

[0031]FIG. 1 shows an extrusion assembly 100 of an indirect extrusion type for production of high-performance extrusion structures. Extrusion assembly 100 may include a shear tool 2 that is configured to apply a rotational shear (shearing) force 26 and an axi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com