Extra-fine copper alloy wire, extra-fine copper alloy twisted wire, coaxial cable, multi-core cable and manufacturing method thereof

A copper alloy wire, coaxial cable technology, applied in the direction of coaxial cable/analog cable, manufacturing coaxial cable, cable/conductor manufacturing, etc., can solve the problems of reduced tensile strength, insufficient bending, insufficient strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Fabrication of Cu-Ag alloy wires.

[0084] Add 2.0% by weight of silver to oxygen-free copper, elongation (%). Furthermore, as the evaluation of heat resistance, heat processing was performed at 350 degreeC for 5 second, and the intensity change of the tensile strength after that was compared. Then wire drawing is carried out until the wire diameter is 0.025-0.010 mm, and an ultra-fine copper alloy wire is obtained. Then, the obtained ultrafine copper alloy wire is heat-treated under heat treatment conditions within a prescribed range to produce an ultrafine copper alloy wire.

[0085] The tensile strength (MPa), electrical conductivity (%IACS), and elongation (%) of the produced ultrafine copper alloy wires of various sizes were measured. Furthermore, as the evaluation of heat resistance, heat processing was performed at 350 degreeC for 5 second, and the intensity change of the tensile strength after that was compared. Here, the heat resistance was evaluated by the ...

Embodiment 2

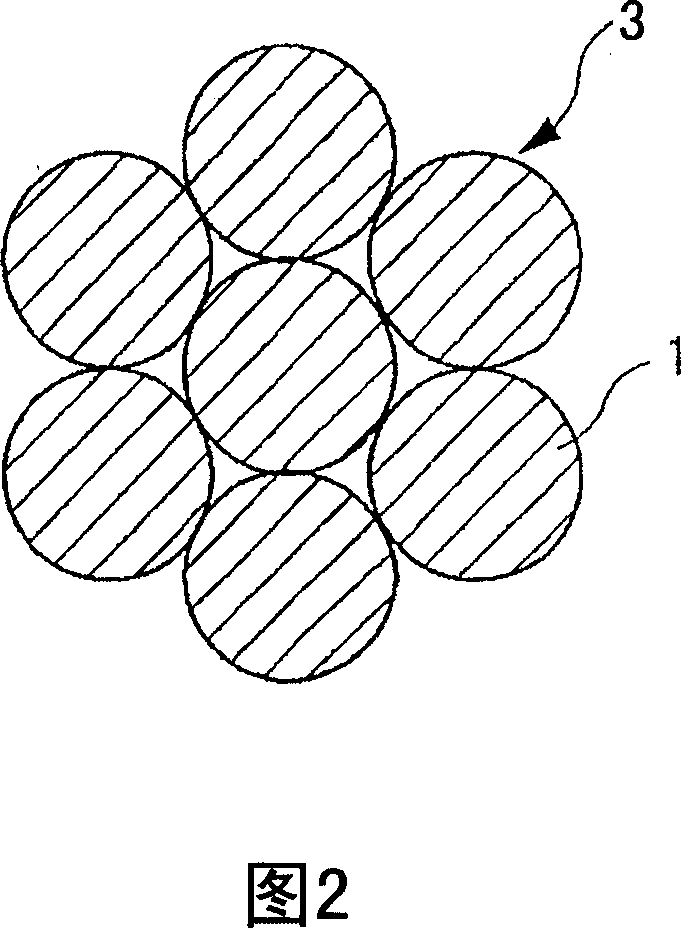

[0089] Next, the production of Cu-Ag alloy stranded wire will be described.

[0090] 2.0% by weight of silver was added to oxygen-free copper, heated and melted in a graphite crucible fixed in a vacuum box, and then cast into a Φ8.0mm wire billet by continuous casting using a graphite mold. Thereafter, through wire drawing, intermediate annealing, wire drawing, and silver plating, and then further wire drawing until the wire diameter is 0.025-0.010 mm, an ultra-fine copper alloy wire is obtained. Furthermore, seven ultrafine copper alloy wires obtained for each size were twisted to obtain an ultrafine copper alloy twisted wire.

[0091] The tensile strength (MPa), electrical resistance (Ω / km), and elongation (%) of the produced ultrafine copper alloy wires of various sizes were measured. Furthermore, as the evaluation of heat resistance, heat processing was performed at 350 degreeC for 5 second, and the intensity change of the tensile strength after that was compared. Here, ...

Embodiment 3

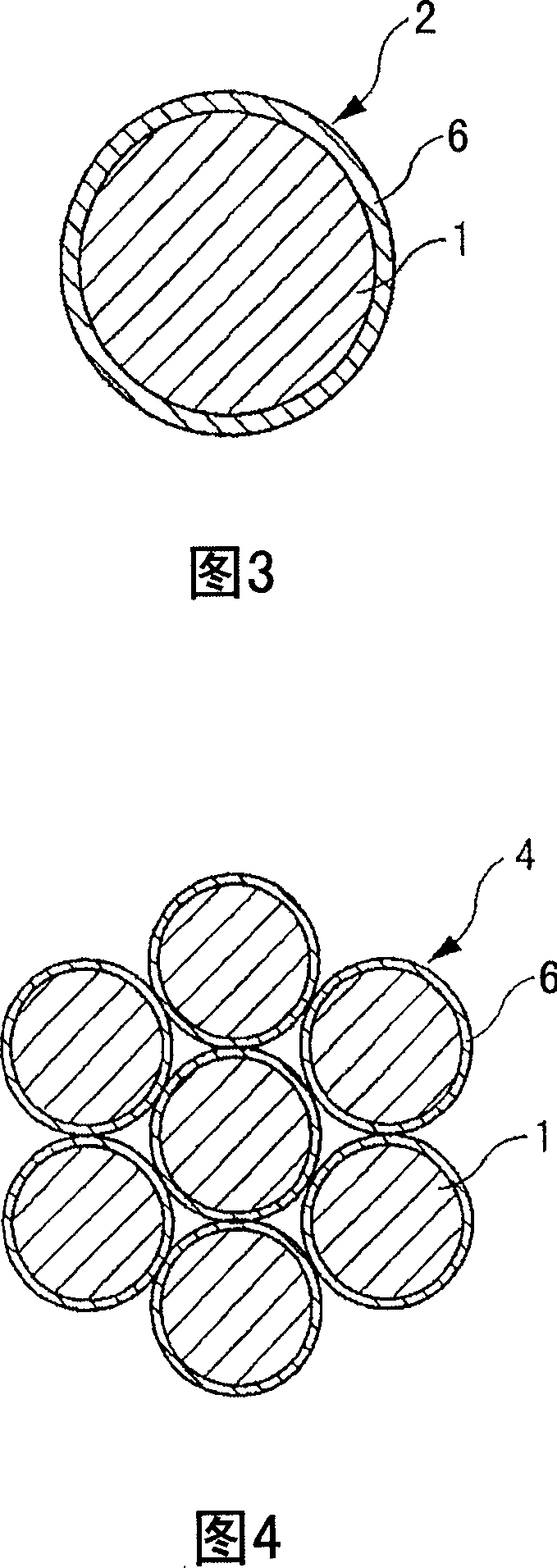

[0172] Manufacture of 43AWG coaxial cables.

[0173] 2.0% by weight of silver was added to oxygen-free copper, and after heating and melting in a graphite crucible fixed in a vacuum box, a graphite mold was used to continuously cast to produce a Φ8mm wire billet. Thereafter, through wire drawing, intermediate annealing, wire drawing, and Ag plating on the final wire to make the coating thickness reach 1 μm, and then wire drawing to obtain a wire diameter of 0.023 mm to obtain an ultra-fine copper alloy wire. Seven such 0.023 mm Ag-plated copper alloy wires (Cu-2%Ag) were prepared and twisted at a pitch of 1.1 mm to produce a twisted wire with an outer diameter of 0.069 mm. Then, the obtained twisted wires were subjected to five types of moving heat treatments in a heat treatment furnace heated at 350° C. to obtain ultrafine copper alloy twisted wires.

[0174] The tensile strength and electrical resistance before and after heat treatment of this ultrafine copper alloy strande...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com