Three-coaxial mineral insulated cable and manufacturing method thereof

A mineral insulated cable, triaxial technology, applied in the direction of insulated cable, coaxial cable manufacturing, cable/conductor manufacturing, etc., can solve the problems of signal influence, low mechanical strength, material aging, etc., to achieve less signal interference, use Wide range and long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

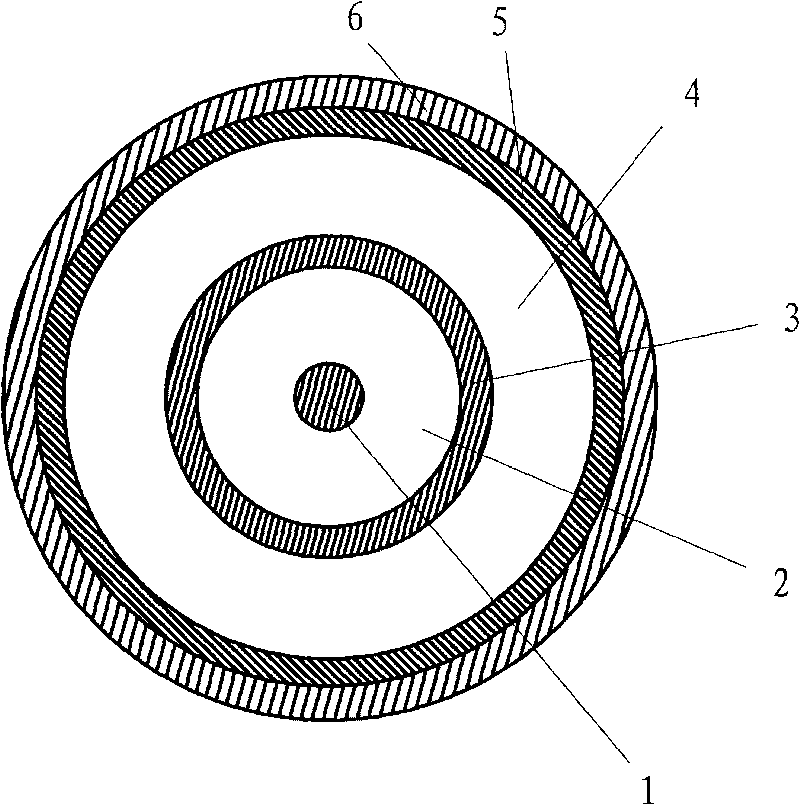

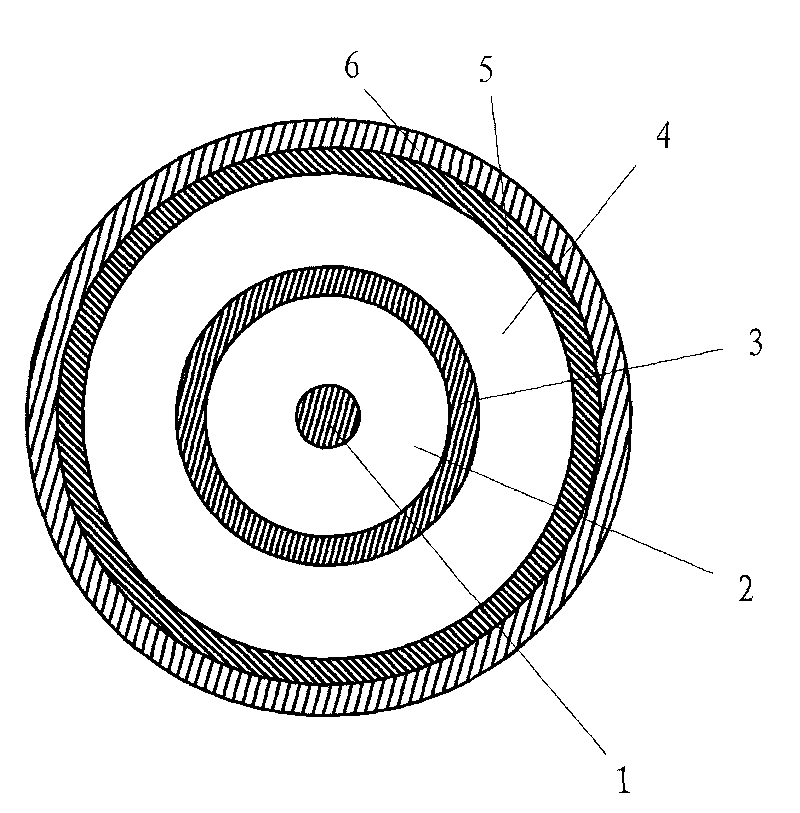

[0032] like figure 1 As shown, the triaxial mineral insulated cable includes an inner conductor layer 1, an inner insulating dielectric layer 2, an inner shielding layer 3, an outer insulating dielectric layer 4, an outer shielding layer 5 and a sheath layer 6 from the inside to the outside. The dielectric layer 2 and the outer insulating dielectric layer 4 are magnesium oxide. The diameter of the cable conductor is 0.6mm, the thickness of the inner insulating layer 2 is 0.35mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com