Method for preparing tin dioxide and titanium dioxide nano cable

A technology of nano-cable and tin dioxide, which is used in the manufacture of coaxial cables, nanotechnology, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

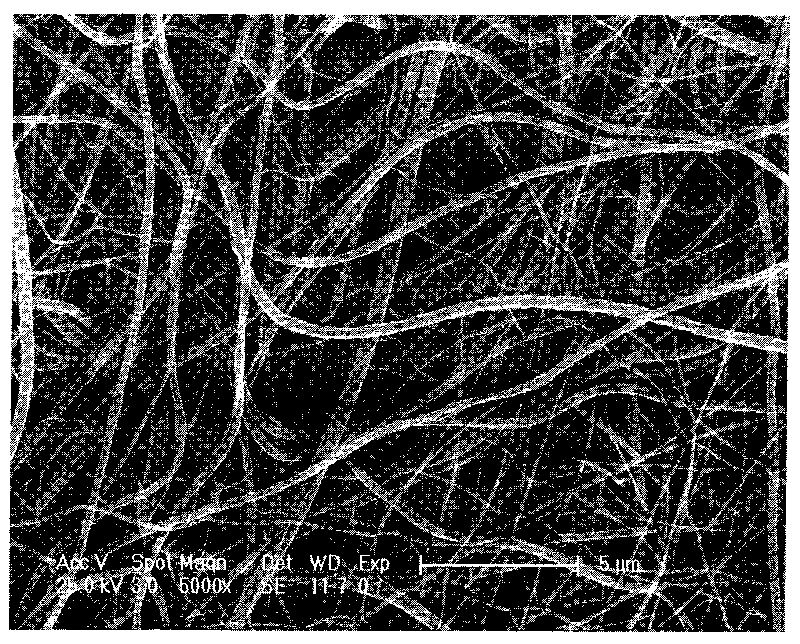

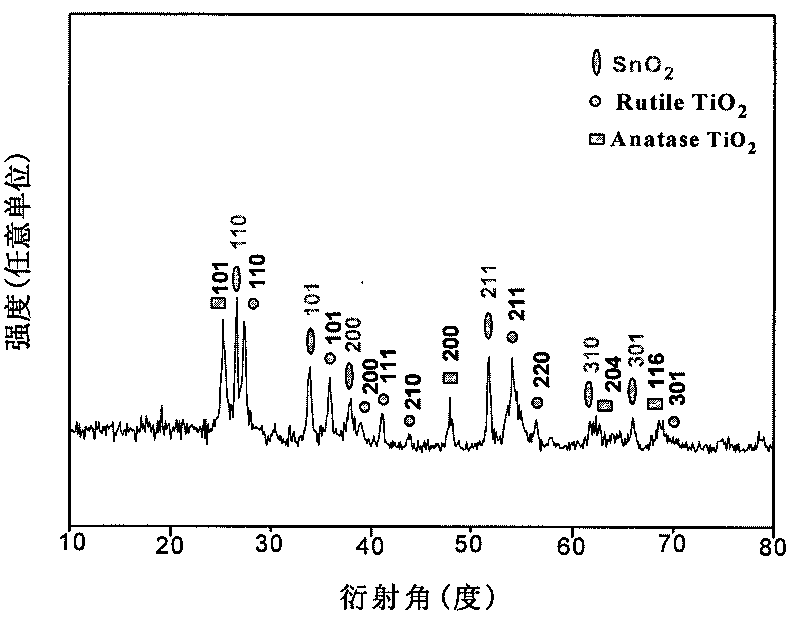

[0020] Embodiment 1: tin tetrachloride pentahydrate and polyvinylpyrrolidone (PVP) are joined in the mixed solvent (volume ratio 5: 1) of N, N-dimethylformamide (DMF) and glycerol, magnetic stirring under room temperature 4h, and let it stand for 2h to form the core spinning solution. The mass percentages of each substance in the core spinning solution are: 11% of PVP, 7% of tin tetrachloride, and 82% of DMF+glycerin. Add a certain amount of polyvinylpyrrolidone (PVP) into the mixture of butyl titanate and absolute ethanol (volume ratio 1:4), stir magnetically for 3 hours at room temperature, and let it stand for 2 hours to form a shell spinning solution. . The mass percent of each substance in the shell spinning solution is: PVP 7%, ethanol + butyl titanate 93%. Coaxial electrospinning technology is used for spinning. The composition of the coaxial nozzle adopts a truncated 10# stainless steel injection needle (outer diameter = 1.0mm, inner diameter = 0.7mm) as the inner s...

Embodiment 2

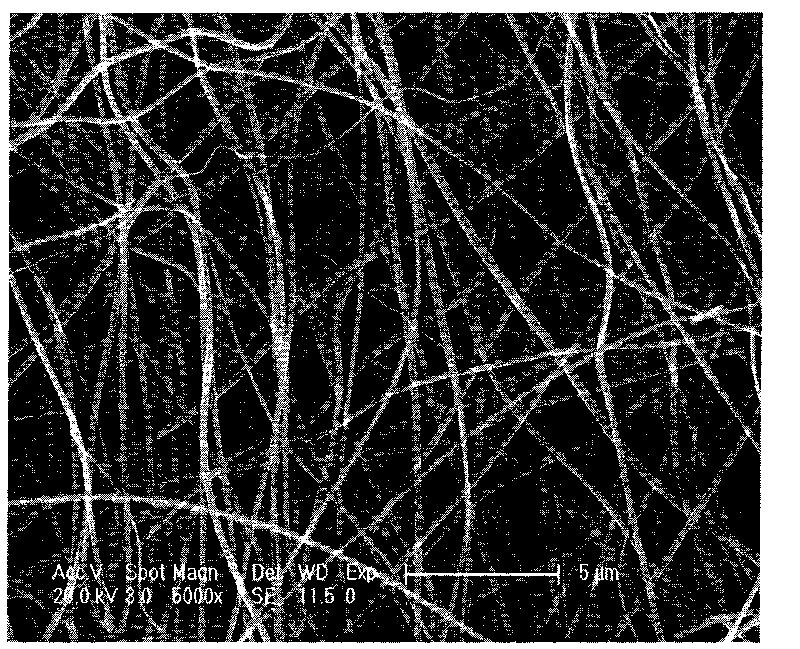

[0021] Embodiment 2: Add tin tetrachloride pentahydrate and polyvinylpyrrolidone (PVP) into the mixed solvent (volume ratio 5: 1) of N, N-dimethylformamide (DMF) and glycerol, magnetic stirring under room temperature 6h, and let it stand for 3h to form the core spinning solution. The mass percent of each substance in the core layer spinning solution is: 15% of PVP, 10% of tin tetrachloride, and 75% of DMF+glycerin. Add a certain amount of polyvinylpyrrolidone (PVP) into the mixed solution of butyl titanate and absolute ethanol (volume ratio 1:4), stir magnetically at room temperature for 6 hours, and let it stand for 3 hours to form a shell spinning solution. . The mass percentage of each substance in the shell spinning solution is: PVP 10%, ethanol + butyl titanate 90%. Coaxial electrospinning technology is used for spinning. The composition of the coaxial nozzle adopts a truncated 10# stainless steel injection needle (outer diameter = 1.0mm, inner diameter = 0.7mm) as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com