Method for manufacturing microlens array

A microlens array and array technology, which is applied in the field of preparation of columnar microlens arrays, can solve problems such as the influence of refractive index, the application of columnar micro-concave lens arrays can not achieve the desired effect, and severe shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

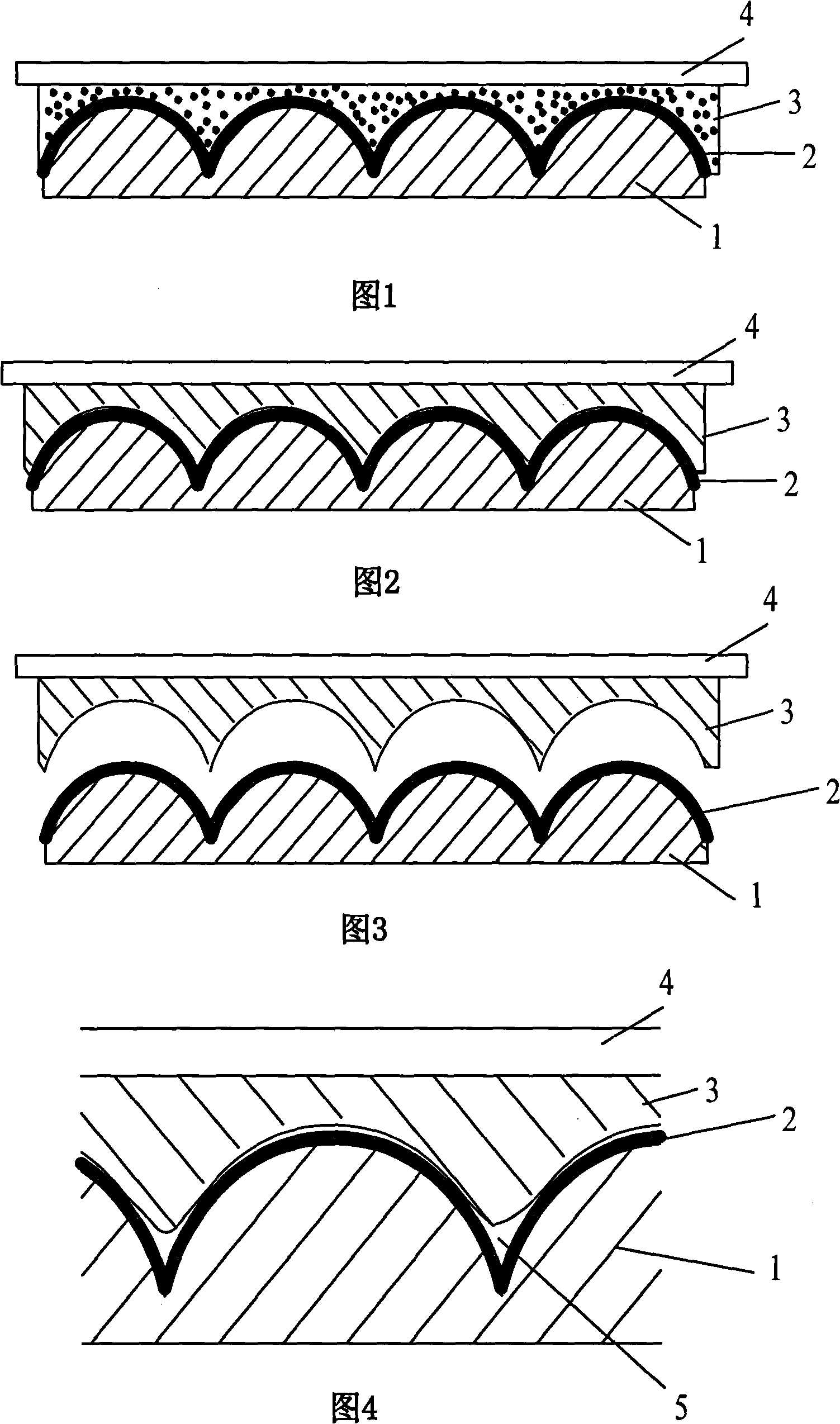

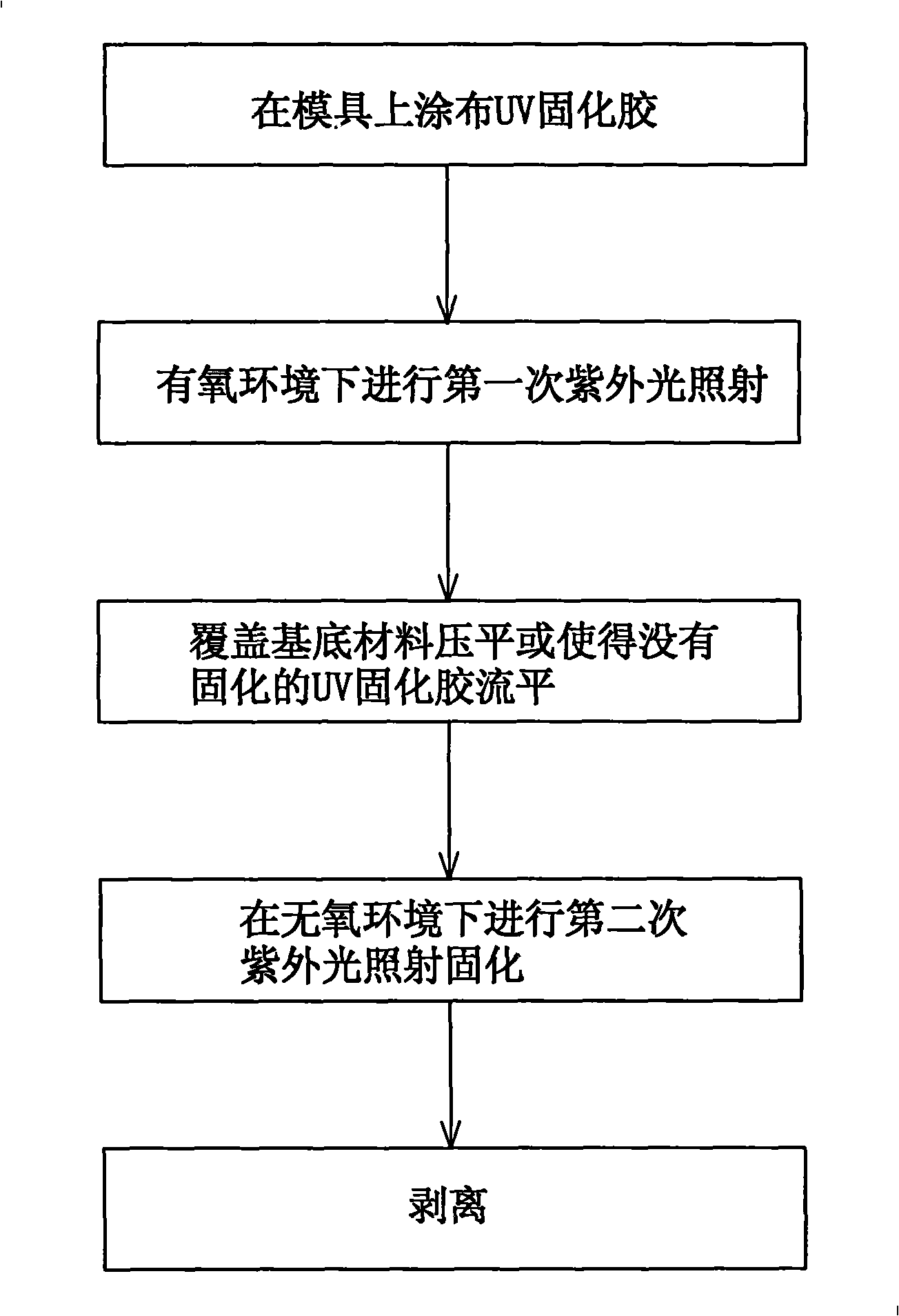

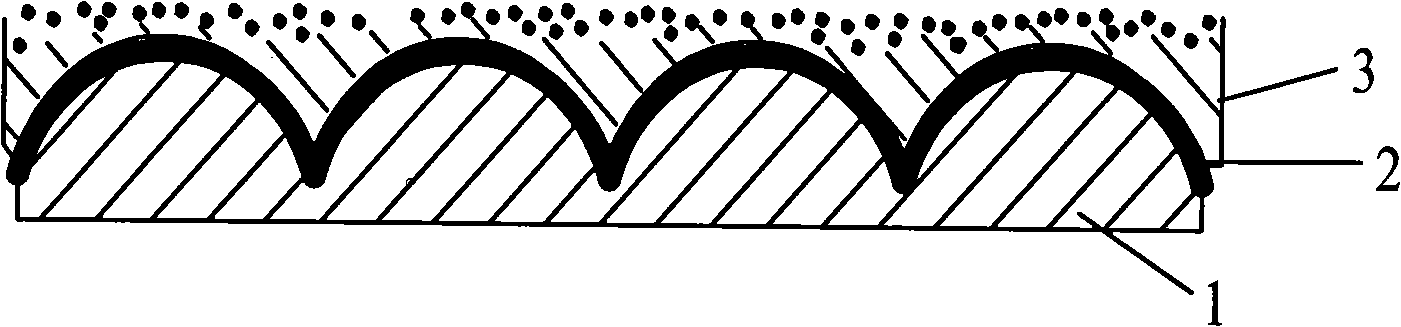

[0032] The preparation method of the present invention is as follows Figure 5 As shown, this embodiment is also described by using a cylindrical micro-convex array mold to prepare a columnar micro-concave lens array as an example, including the following steps:

[0033] Step 1: Coating UV curable glue on the mold (in this embodiment, oxygen-inhibited UV curable glue is selected). Using UV curing rubber roller coating equipment to apply and level the UV curing glue can make the UV curing glue about 30um higher than the highest point of the columnar micro-convex row array mold, which can be flexibly adjusted according to the required thickness.

[0034] Step 2: Place the mold coated with UV curable adhesive in an aerobic environment for the first ultraviolet light irradiation. A 60-watt ultraviolet lamp can be used for irradiation, the irradiation distance is 50cm, and the irradiation time is less than 1 minute (the length of time can be flexibly set according to the specific s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com