Casting molding template and casting molding process for constructional columns of infilled walls

A technology for forming templates and structural columns, which is applied in the direction of formwork/formwork/work frame, building construction, construction, etc., can solve the problems of manpower, materials, construction period waste, environmental pollution, etc., and achieve pollution reduction, easy operation, The effect of simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

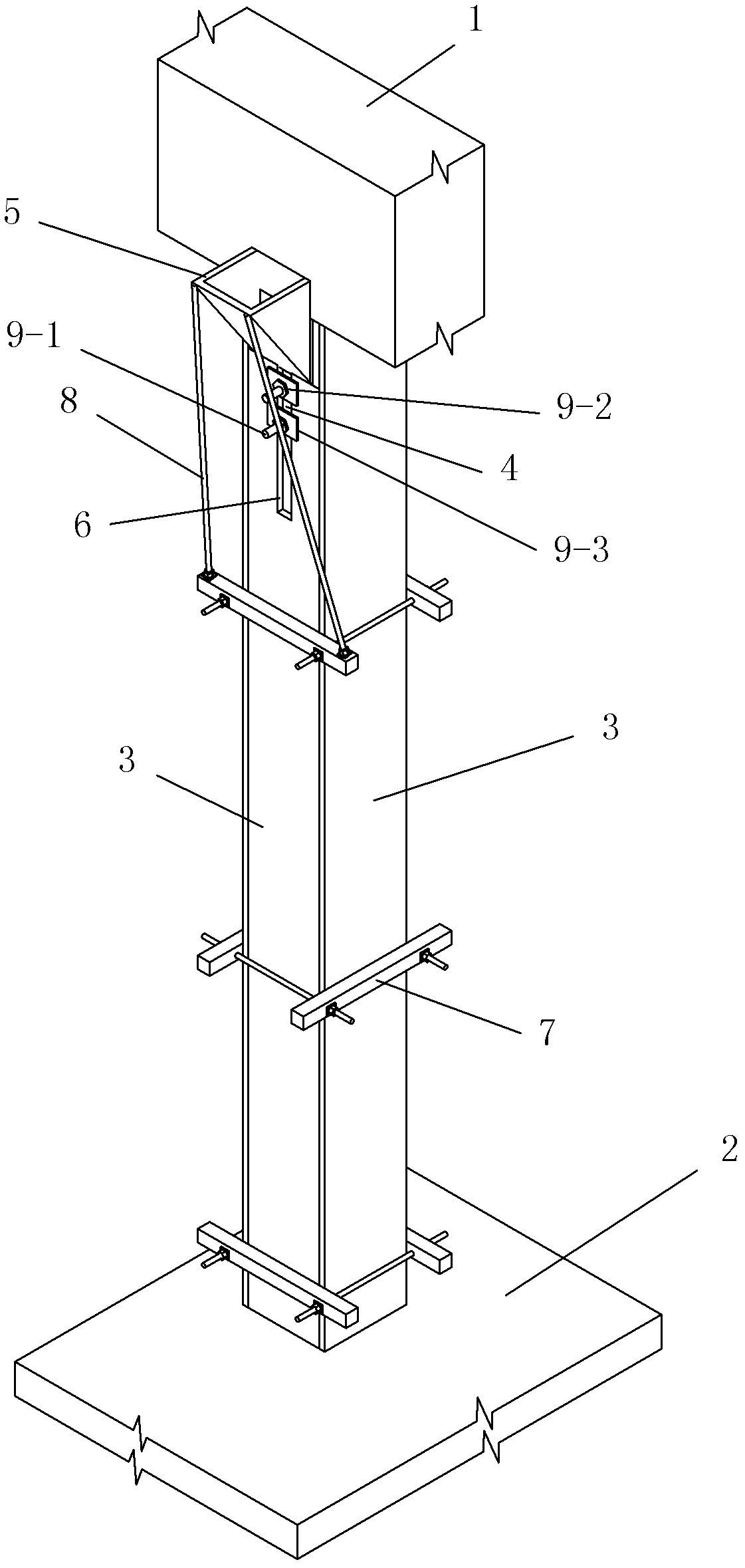

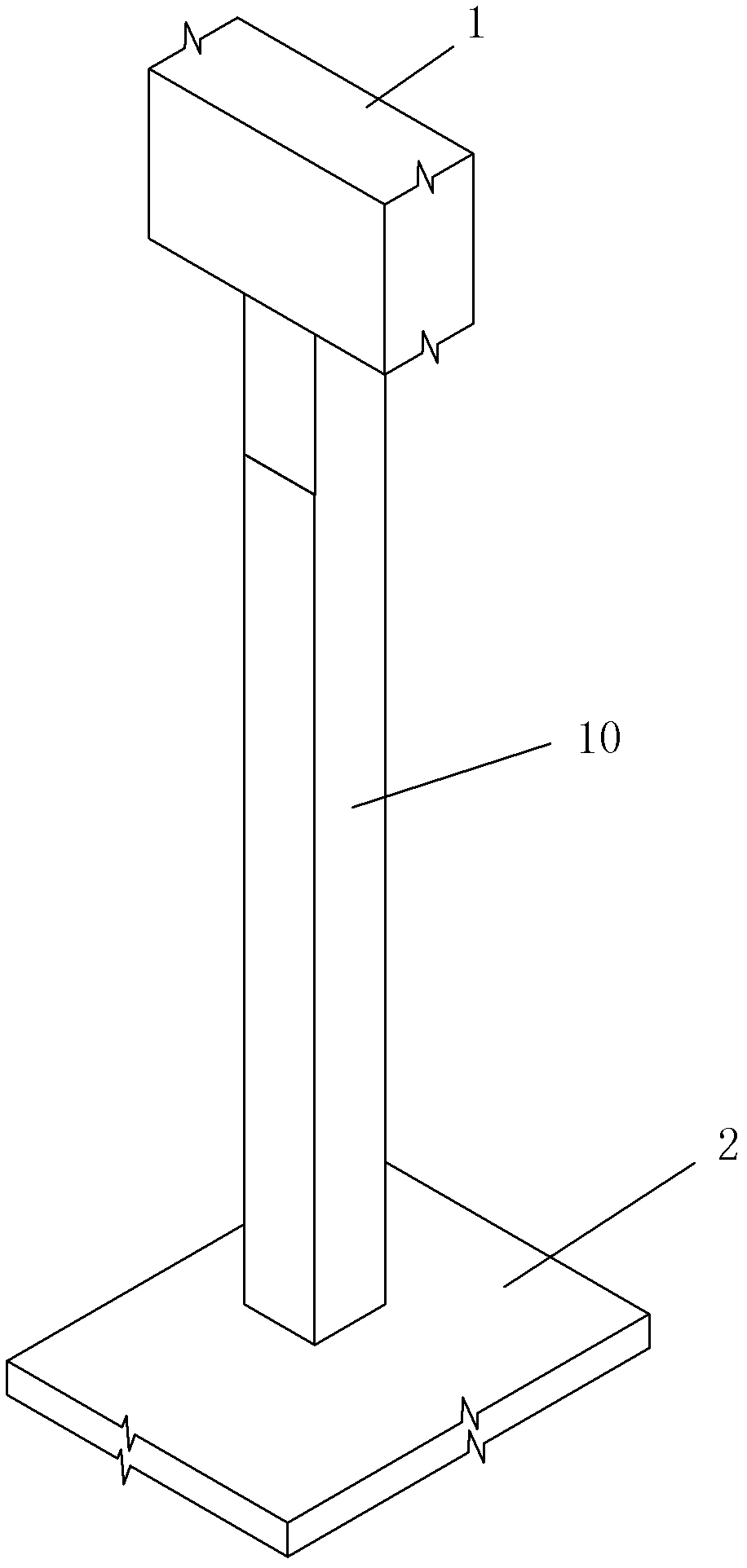

[0043] Such as figure 1 A filling wall construction column pouring forming formwork is shown, including a lining formwork 4 and a main body formwork with an inner lining diaphragm installation opening for the lining formwork 4 to be installed at the upper end, the lining formwork 4 and the main body The formwork is assembled to form a structural column formwork. The structure and size of the internal molding cavity of the structural column formwork are the same as those of the structural column of the filling wall to be constructed, and the structural column formwork is supported on the floor 2 and arranged above the floor 2. between frame beams 1. A horn-type feeding device 5 is installed on the installation port of the lining membrane, and the horn-type feeding device 5 is located outside the structural column formwork, and the height of the upper feeding port of the horn-type feeding device 5 is not lower than The height of the bottom of the frame beam 1 and the structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com