Roof panel and method of manufacturing said panel

A panel and canopy technology, applied in the direction of roof, engine sealing, household components, etc., can solve the problems of unqualified geometric shape, scrap, damaged panels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

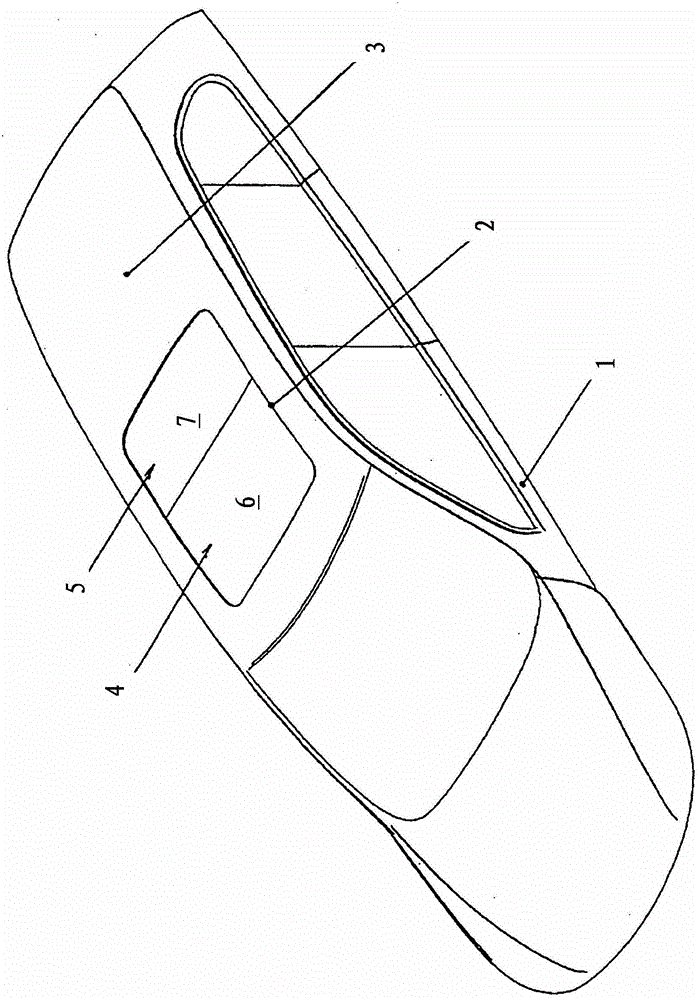

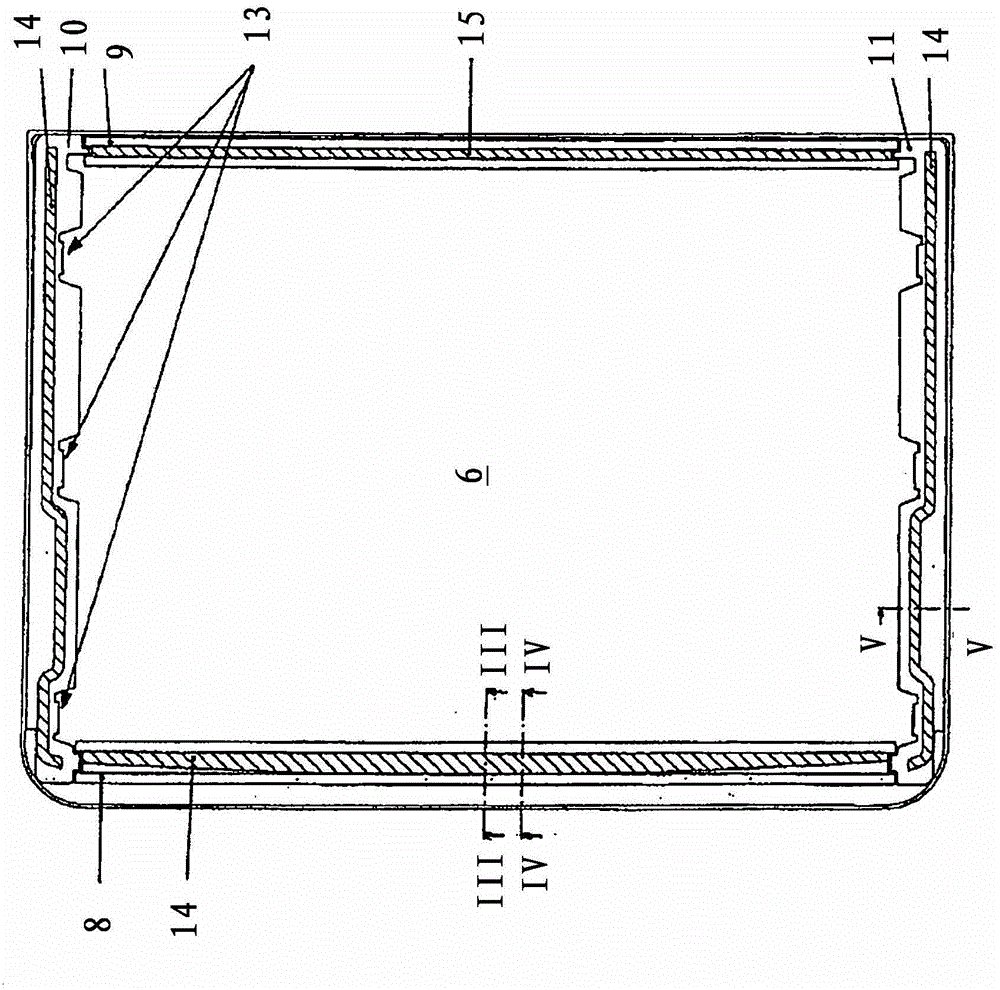

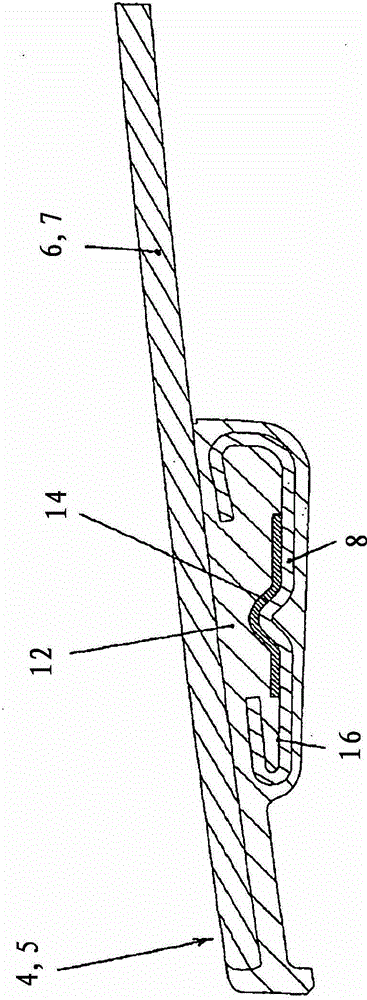

[0022] figure 1 One embodiment of an open roof structure for a vehicle 1 is shown, comprising a roof opening 2 provided in a fixed roof part 3 of the vehicle. The front panel 4 and the rear panel 5 of the open roof structure are able to close and at least partially open said roof opening 2 . The front panel 4 is movable along longitudinal guides (not shown, but known per se) on opposite sides of the roof opening 2 . The rear end of the rear panel 5 can only be moved in the vertical direction, thereby freeing an opening at the rearmost side of the open roof structure. Both panels 4 and 5 can be moved manually or by drive means not shown but known per se. The cooperation between the panels 4 and 5 and the longitudinal guides can take place in any known manner and is not illustrated in detail. The invention is applicable to all types of open roof structures comprising one or more panels, in particular glass panels, but also panels made of other materials such as plastic.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com