Water-borne epoxy resin modified cement grouting material

A water-based epoxy resin and cement grouting technology, used in the field of cement grouting materials, can solve the problems of poor durability, low flexural strength, and poor grouting joints, and achieves improved compressive strength, good bonding performance, and improved The effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

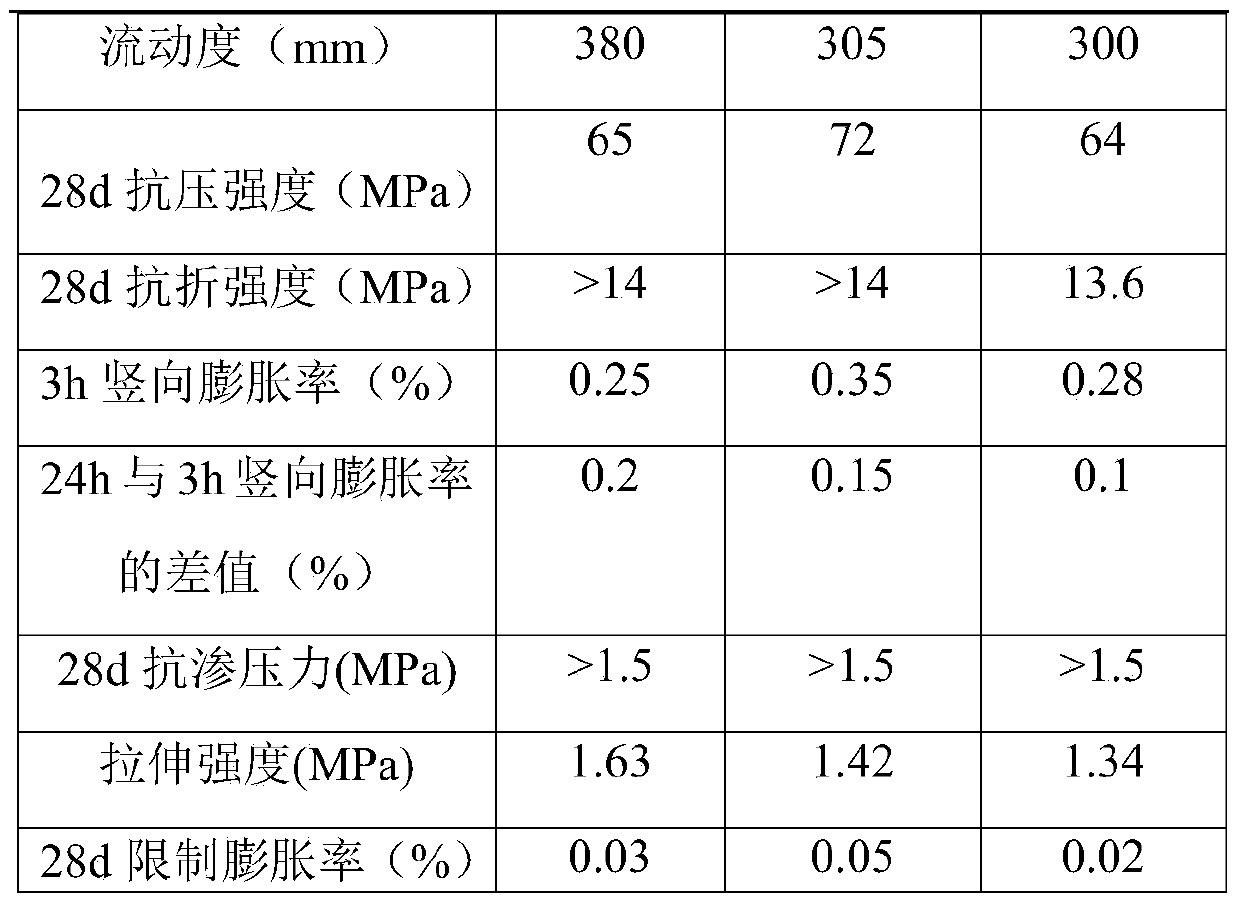

Embodiment 1

[0027] The invention relates to a water-based epoxy resin modified cement grouting material. The typical application of this example is bridge tunnel grouting. It is prepared from the following raw materials at room temperature according to weight ratio:

[0028] 10 parts of water-based epoxy resin system, including 4 parts of Shell 828 epoxy resin and 6 parts of American Gas Chemical 721 curing agent

[0029] Tangshan Jidong Cement Co., Ltd. P·O42.5 Ordinary Portland Cement 45 parts

[0030] 10 parts of 200 mesh quartz powder

[0031] 5 parts of calcium carbonate powder with particle size of 300 mesh

[0032] Suzhou FOX8H polycarboxylate superplasticizer 0.6 parts

[0033] Composite expansion agent 8 parts

[0034] 1 part of powder pitch with average particle size ≤ 100um

[0035] 0.02 parts of low-viscosity cellulose with a viscosity of 100mpa.s

[0036] Sodium citrate retarder 0.01 parts

[0037] The amount of water added is 14% of the total weight of the material.

...

Embodiment 2

[0041] The invention relates to a water-based epoxy resin modified cement grouting material. This example is suitable for the use of ordinary grouting grout. It is prepared from the following raw materials at room temperature according to the weight ratio:

[0042] 8 parts of water-based epoxy resin system, including 6 parts of E51 epoxy resin and 2 parts of American Gas Chemical 701 curing agent

[0043] Tangshan Jidong Cement Co., Ltd. P·O42.5 Ordinary Portland Cement 35 parts

[0044] Tangshan Polar Bear Building Materials Co., Ltd. 5 parts of fast-hardening sulfoaluminate cement

[0045] 40 parts of continuously graded quartz sand with particle size less than 2.36m

[0046] Composite expansion agent 6 parts

[0047] Jiangsu Bote New Material Co., Ltd. PCA(Ⅰ) polycarboxylate superplasticizer 0.5 parts

[0048] 1 part powdered asphalt

[0049] 7 parts of 200 mesh particle size calcium carbonate powder

[0050] Viscosity is 0.03 parts of low-viscosity cellulose of 200mpa.s...

Embodiment 3

[0055] The present invention relates to water-based epoxy resin modified cement grouting material, this example is prepared by weight ratio from the following raw materials:

[0056] 7.5 parts of water-based epoxy resin system, including 6 parts of Zhejiang Anbang water-based epoxy resin emulsion (solid content is 50%), and 2 parts of supporting curing agent for Zhejiang Anbang water-based epoxy resin emulsion

[0057] Tangshan Jidong Cement Co., Ltd. P·O42.5 Ordinary Portland Cement 40 parts

[0058] Tangshan Polar Bear Building Materials Co., Ltd. 10 parts of fast-hardening sulfoaluminate cement

[0059] 20 parts of 300 mesh quartz powder

[0060] Composite expansion agent 6 parts

[0061] Sika Viscocrete-125P polycarboxylate superplasticizer 0.2 parts

[0062] 0.50 parts of powder pitch

[0063] Calcium carbonate powder 2.5 parts

[0064] Viscosity is 0.02 parts of low-viscosity cellulose of 300mpa.s

[0065] L-type tartaric acid retarder 0.03 part

[0066] The amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com