Storage battery anode lead plaster capable of enhancing SAE standard high temperature service life and preparation method

A positive lead paste, battery technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of reduced electrical conductivity, reduced energy, agglomeration of positive active materials, etc., to extend high temperature cycle life, long high temperature life , the effect of improving conductivity and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

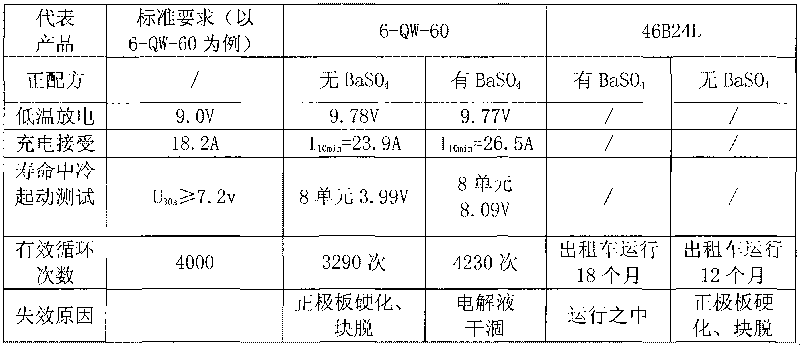

Examples

Embodiment 1

[0026] Embodiment 1: the lead powder that 100kg PbO content is 70%~85% is added in the plaster mixing machine, add the fiber of 0.05kg, the superfine barium sulfate of 0.05kg carbon black, 0.1kg simultaneously, above-mentioned material is stirred, then Add 10kg of purified water dissolved with 0.1kg of magnesium sulfate, mix evenly in the wet state, and quickly drench with a density of 1.400g / cm 3 (25°C) sulfuric acid solution 4kg, during the mixing process, control the paste temperature to be less than 65°C, the reaction is uniform and the temperature drops below 45°C, and the paste can be used.

Embodiment 2

[0027] Embodiment 2: 100kgPbO content is that the lead powder of 70%~85% is added in the paste machine, add the fiber of 0.07kg, the superfine barium sulfate of 0.1kg carbon black, 0.5kg at the same time, above-mentioned materials are stirred, then add 11kg of purified water dissolved with 0.2kg of magnesium sulfate, mixed evenly in the wet state, quickly poured in with a density of 1.400g / cm 3 (25°C) sulfuric acid solution 6kg, during the mixing process, control the temperature of the paste to be less than 65°C, the reaction is uniform and the temperature drops below 45°C, and the paste can be used.

Embodiment 3

[0028] Embodiment 3: the lead powder that 100kg PbO content is 70%~85% is added in the plaster mixing machine, add the fiber of 0.1kg, the superfine barium sulfate of 0.2kg carbon black, 0.8kg simultaneously, above-mentioned material is stirred, then Add 12kg of purified water dissolved with 0.4kg of magnesium sulfate, mix evenly in the wet state, and quickly drench with a density of 1.400g / cm 3 (25°C) sulfuric acid solution 8kg, during the mixing process, the temperature of the mixing paste is controlled to be less than 65°C, the reaction is uniform and the temperature drops below 45°C, and the paste can be used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com