Self-tension cloth storage device

A cloth storage device and tension technology, applied in the direction of processing textile material carriers, etc., can solve the problems of slow cloth storage process, cumbersome hydraulic mechanism operation, cloth shrinkage, etc., and achieve the goal of solving shrinkage problems, improving stability, and increasing cloth storage speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

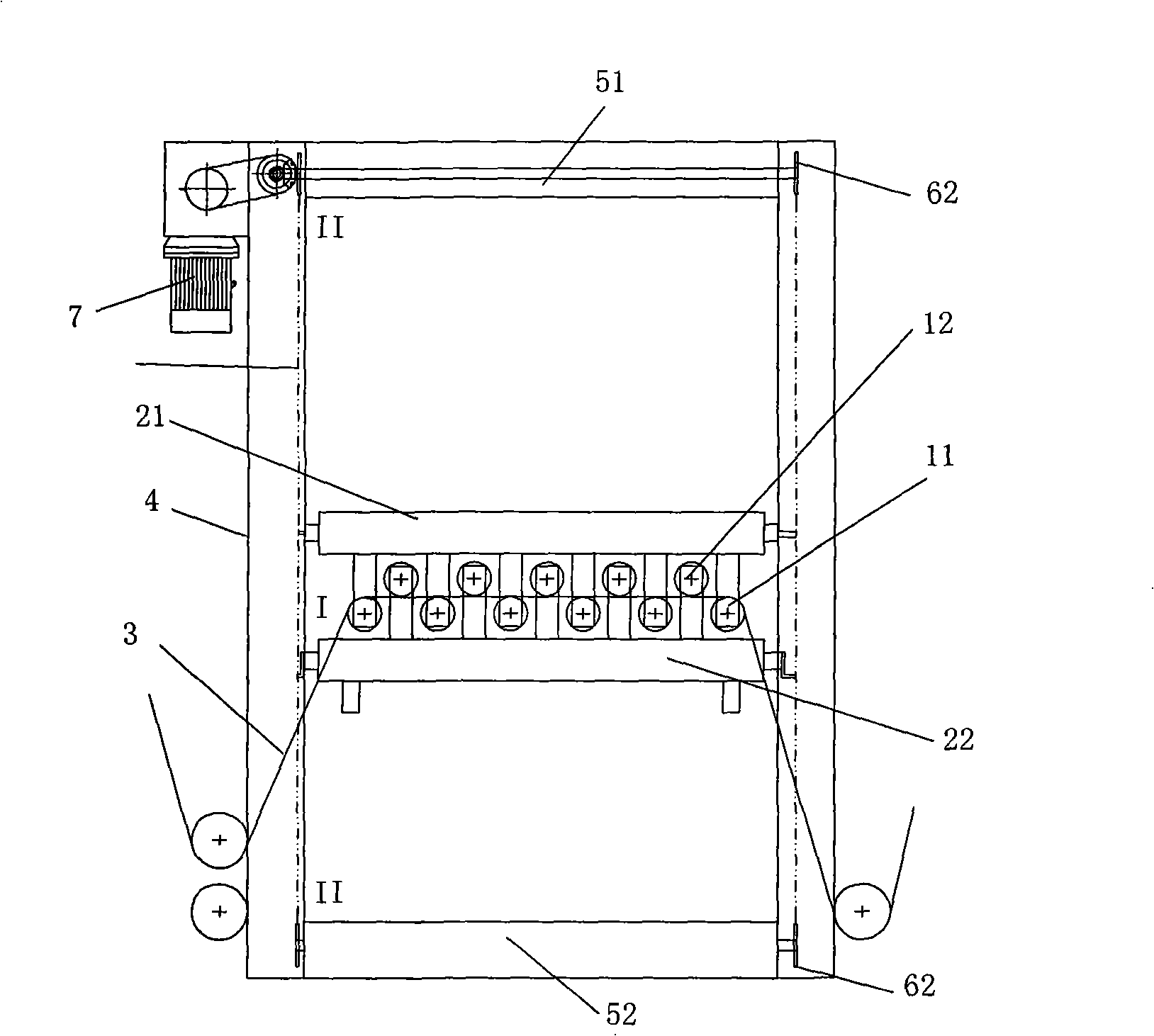

[0024] Referring to Fig. 3(a), the upper row of rollers 11 and the lower row of rollers 12 are arranged oppositely, and the fabric 3 is led out alternately in a "Z" shape on the upper row of rollers 11 and the lower row of rollers 12.

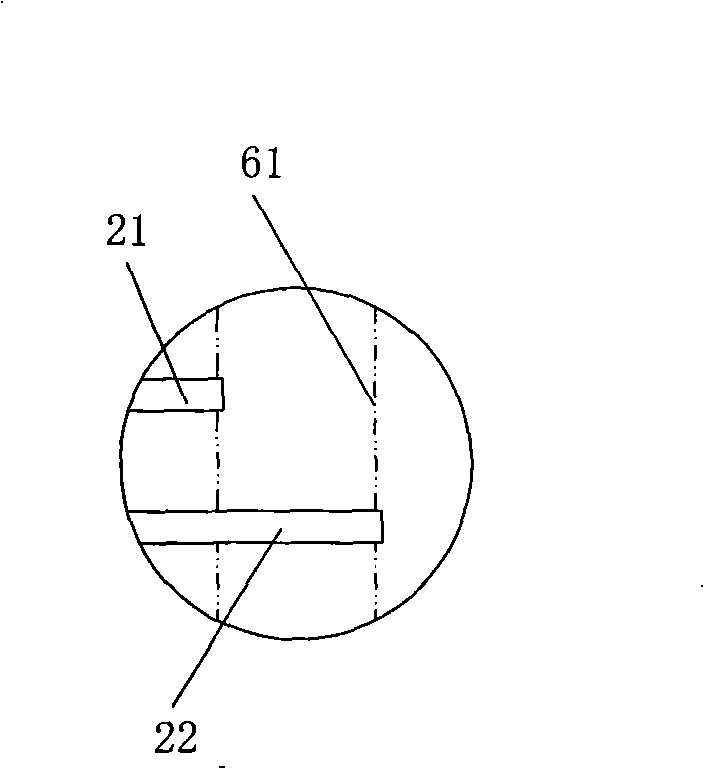

[0025] As shown in Figure 3 (a), in this embodiment, a transmission structure is arranged in a rectangular frame in the cloth storage box 4, and the top frame and the bottom frame of the rectangular frame are respectively the top rod 51 and the bottom of which are provided with sprockets 62 at both ends. Rod 52, the two sides of the rectangular frame are annular transmission chains 61, the annular transmission chain 61 and the sprockets 62 at the corresponding positions of the top rod 51 and the bottom rod 52 constitute a chain sprocket transmission structure, and the upper row of roller frames parallel to each other 21 and the lower row of roller frames 22 are respectively hung on the drive chain 61 at their respective ends, and the upper row o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com