Invert-emulsion drilling fluid, preparation method and application thereof

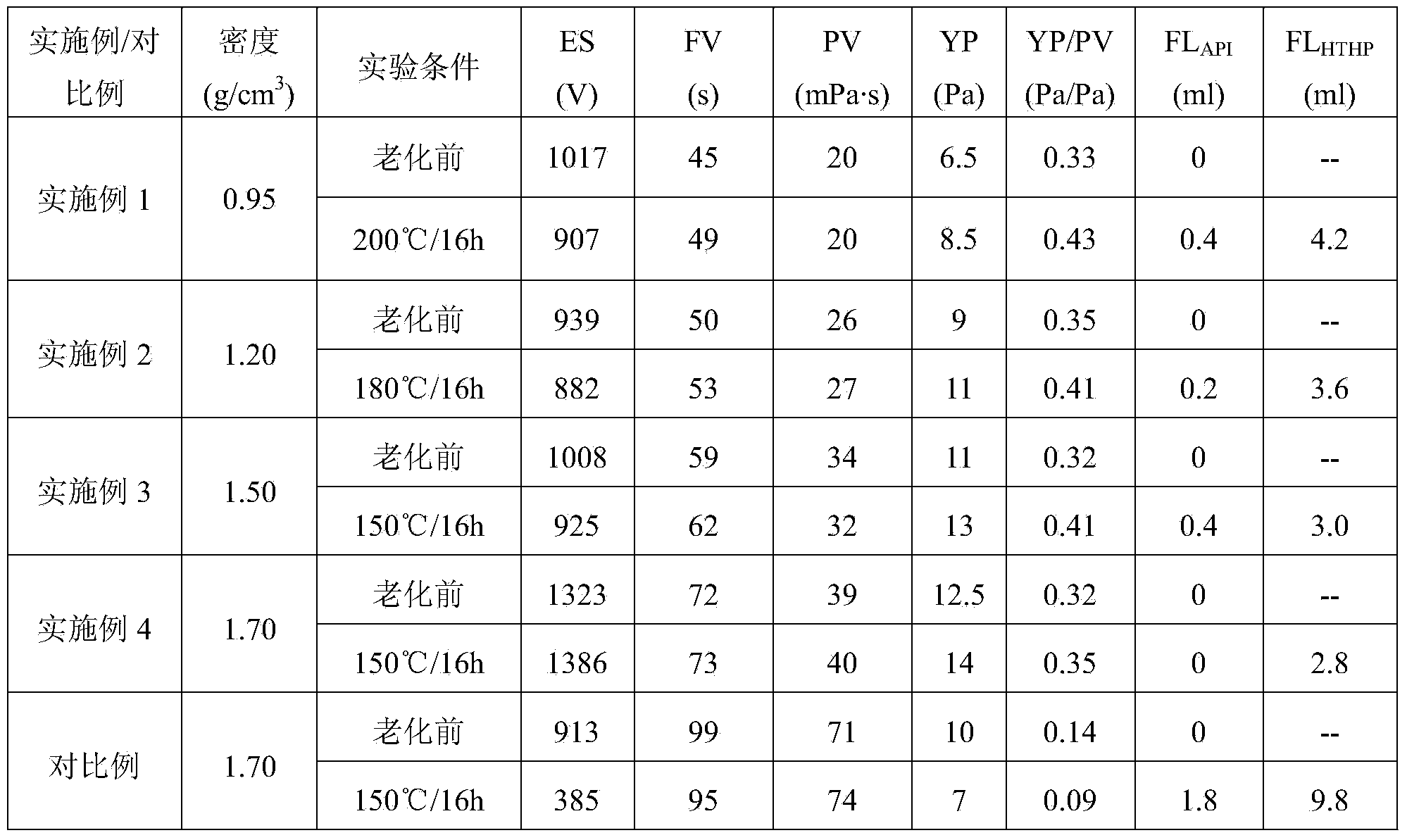

A drilling fluid and inverse emulsification technology, used in chemical instruments and methods, earth-moving drilling, flushing wells, etc., can solve the problems of high viscosity and plastic viscosity, low dynamic shear force and static shear force, etc., and achieve good biodegradation. properties, improve shear force, and promote the effect of drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0038] (1) The waste oil used in the preparation example is rapeseed oil residue (produced by Zhangbei Xixiang Vegetable Oil Purchase and Sales Co., Ltd.), animal oil foot (produced by Hebei Jiajie Oil Co., Ltd.) and restaurant swill oil (collected in the unit restaurant).

[0039] (2) The saponification of the waste oil used in the preparation example is prepared as follows:

[0040] ① Heat a mixture of 100 parts of rapeseed oil residue and 100 parts of calcium oxide and calcium hydroxide (the weight ratio of the two is 3:1) to 65°C, react under stirring conditions for 8 hours, and cool to obtain rapeseed oil saponification.

[0041] ②Heat the mixture of 100 parts of animal oil feet and 10 parts of sodium hydroxide and potassium hydroxide (the weight ratio of the two is 1:1) to 190°C, react under stirring conditions for 1 hour, and cool to obtain the saponification of animal oil feet things.

[0042] ③ Heat 100 parts of restaurant swill oil and 50 parts of calcium oxide to ...

Embodiment 1

[0054] (1) The weight volume content of each component in the inverse emulsified drilling fluid is as follows:

[0055] Base Oil: 75%; Brine: 25%; Emulsifier: 3%; Wetting Agent: 0.2%; Lipophilic Colloid: 3%; Fluid Loss Control Agent: 3%; Shear Lifting Agent: 1%; Alkalinity Regulator : 4%; weighting agent: 0%.

[0056] Among them, the base oil is a mixture of No. 0 diesel oil and No. 5 white oil (both produced by Sinopec Yanshan Petrochemical), and the volume ratio of the two is 1:2; the brine is calcium acetate brine with a mass fraction of 5%; the emulsifier is prepared from The emulsifier 1 that example obtains; Wetting agent adopts tetradecyltrimethylammonium bromide; Lipophilic colloid adopts organic soil; Fluid loss reducer adopts humic acid amide; The mixture, the weight ratio of the two is 1:5; the alkalinity regulator adopts calcium oxide.

[0057] The specific preparation method is as follows:

[0058] (2) The preparation process of the inverse emulsified drilling ...

Embodiment 2

[0063] The weight volume content of each component in the inverse emulsified drilling fluid is as follows:

[0064] Base Oil: 60%; Brine: 40%; Emulsifier: 4%; Wetting Agent: 0.2%; Lipophilic Colloid: 3%; Fluid Loss Control Agent: 4.8%; Shear Lifting Agent: 1%; Alkalinity Regulator : 4%; Weighting agent: 37%.

[0065] Wherein, the base oil adopts No. 0 diesel oil (produced by Sinopec Yanshan Petrochemical); the brine adopts the calcium chloride brine with a mass fraction of 20%; the emulsifier adopts the emulsifier 2 obtained in the preparation example; A mixture of sodium bis(2-ethylhexyl)sulfonate and sodium bis(2-ethylhexyl)sulfonate, the weight ratio of the two is 1:2; the lipophilic colloid is made of organic soil; the fluid loss control agent is made of oxidized asphalt; the shear agent is made of polyethylene The propylene copolymer resin has a viscosity-average molecular weight of 8000; calcium hydroxide is used as the alkalinity regulator; calcium carbonate is used as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com