Treatment method for high-concentration sulfur-containing caustic sludge wastewater from oil refinery

A technology for alkali slag wastewater and treatment method, which is applied in the directions of oxidized water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. To deal with problems such as poor effect, to achieve the effect of convenient operation and maintenance, good biodegradability and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

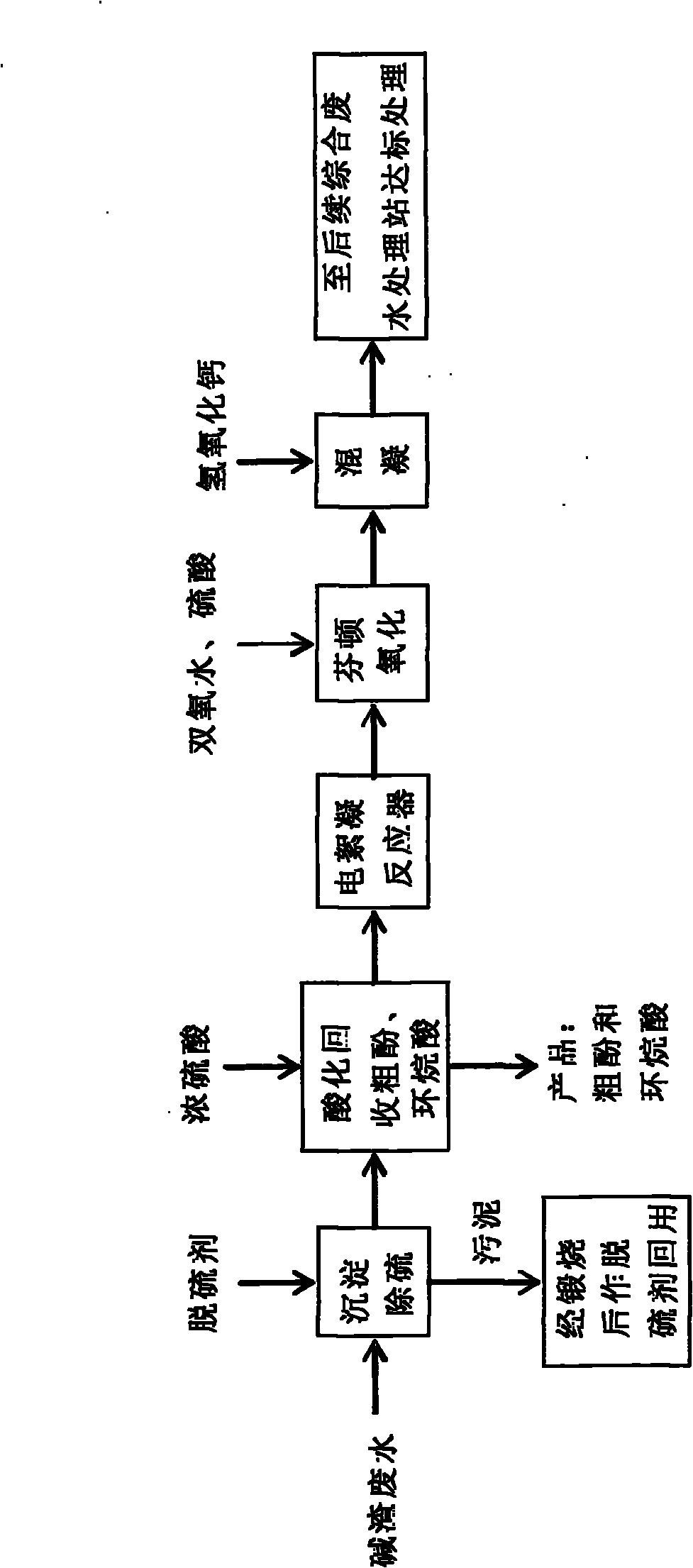

Method used

Image

Examples

Embodiment 1

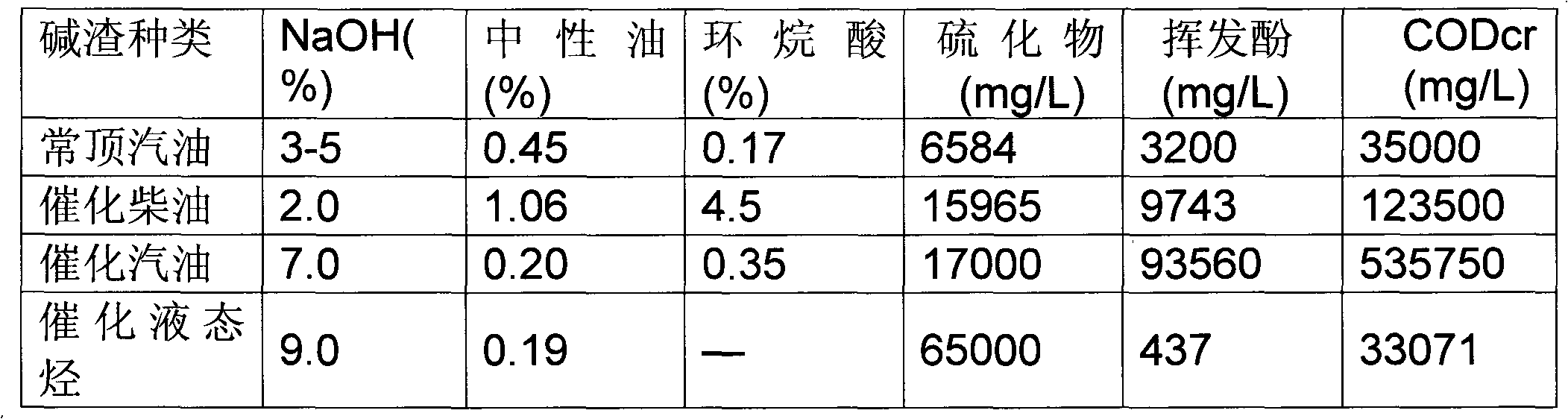

[0034] The source of sewage is catalytic gasoline alkali residue wastewater from a certain oil refinery, in which COD is 456300mg / L, sulfide is 23500mg / L, volatile phenol is 93560mg / L, and the color is greater than 37000 times. Take 2m of catalytic gasoline alkali residue wastewater 3 , add precipitant copper sulfate, the molar ratio of precipitant and sulfide is 1.00:1.00, aeration and stirring for 60 minutes, when the alkali slag wastewater stays in the sedimentation tank for 3 hours, the sulfide in the wastewater is 300mg / L, remove The rate reaches 98.8%, the chromaticity is obviously improved, the toxicity is reduced, and the residual Cu=0.01mg / L. The main component of the produced precipitate is CuS, which can be calcined to generate CuO, which can be directly reused or acidified with sulfuric acid to generate CuSO 4 Use it later.

[0035] The wastewater coming out of the sedimentation tank enters the acidification tank, adjusts the pH to 5.3 with concentrated sulfuric a...

Embodiment 2

[0039]The source of sewage is catalytic diesel alkali residue wastewater from an oil refinery, in which COD is 135600mg / L, sulfide is 12965mg / L, volatile phenol is 9765mg / L, naphthenic acid is 4.5%, and the chromaticity is greater than 45000 times. The catalytic diesel alkali residue wastewater is 20m 3 , add regenerated precipitant copper oxide, the molar ratio of precipitant and sulfide is 1.40:1.00, aerate and stir for 90 minutes, when the alkali slag wastewater stays in the sedimentation tank for 2 hours, the sulfide in the wastewater is 77.8mg / L , the removal rate reached 99.4%, the chroma was significantly improved, the toxicity was reduced, and the residual Cu=1.20mg / L; the effluent went to the acidification tank, and the pH value was adjusted to 5.7 with concentrated sulfuric acid, and stood for 3 hours to recover the crude phenol, and then acidified to The pH value is 3.3, let it stand for 3 hours, and the sulfur-free naphthenic acid is obtained by stratification. At t...

Embodiment 3

[0041] The source of sewage is catalytic diesel alkali residue wastewater from a refinery, in which COD is 30000mg / L, sulfide is 8000mg / L, volatile phenol is 9765mg / L, naphthenic acid is 4.5%, and the chromaticity is greater than 10000 times. The catalytic diesel alkali residue wastewater is 20m 3 , add regenerated precipitant copper oxide, the mol ratio of precipitant and sulfide is 0.6: 1.00, aeration and stirring 30 minutes, when alkali slag waste water is 1 hour in the settling tank, sulfide is 40mg / L in the waste water, The chromaticity is obviously improved and the toxicity is reduced.

[0042] The effluent goes to the acidification tank, the pH value is adjusted to 5.0 with concentrated sulfuric acid, and the phenol is recovered for 2 hours. The crude phenol is then acidified to a pH value of 2.0. The flocculation reactor is set with a current intensity of 15A, an alternating pulse period of 60s, and an electrolysis time of 3 hours, and then flows into the Fenton’s reag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com