Environmental protection type lubricating grease composition and method for preparing same

A lubricating grease composition and composition technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of poor oxidation stability and hydrolysis stability, easy waxing low-temperature fluidity, limited use range, etc., and achieve excellent anti-corrosion Oxidation, good rust and corrosion inhibition performance, good biodegradable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

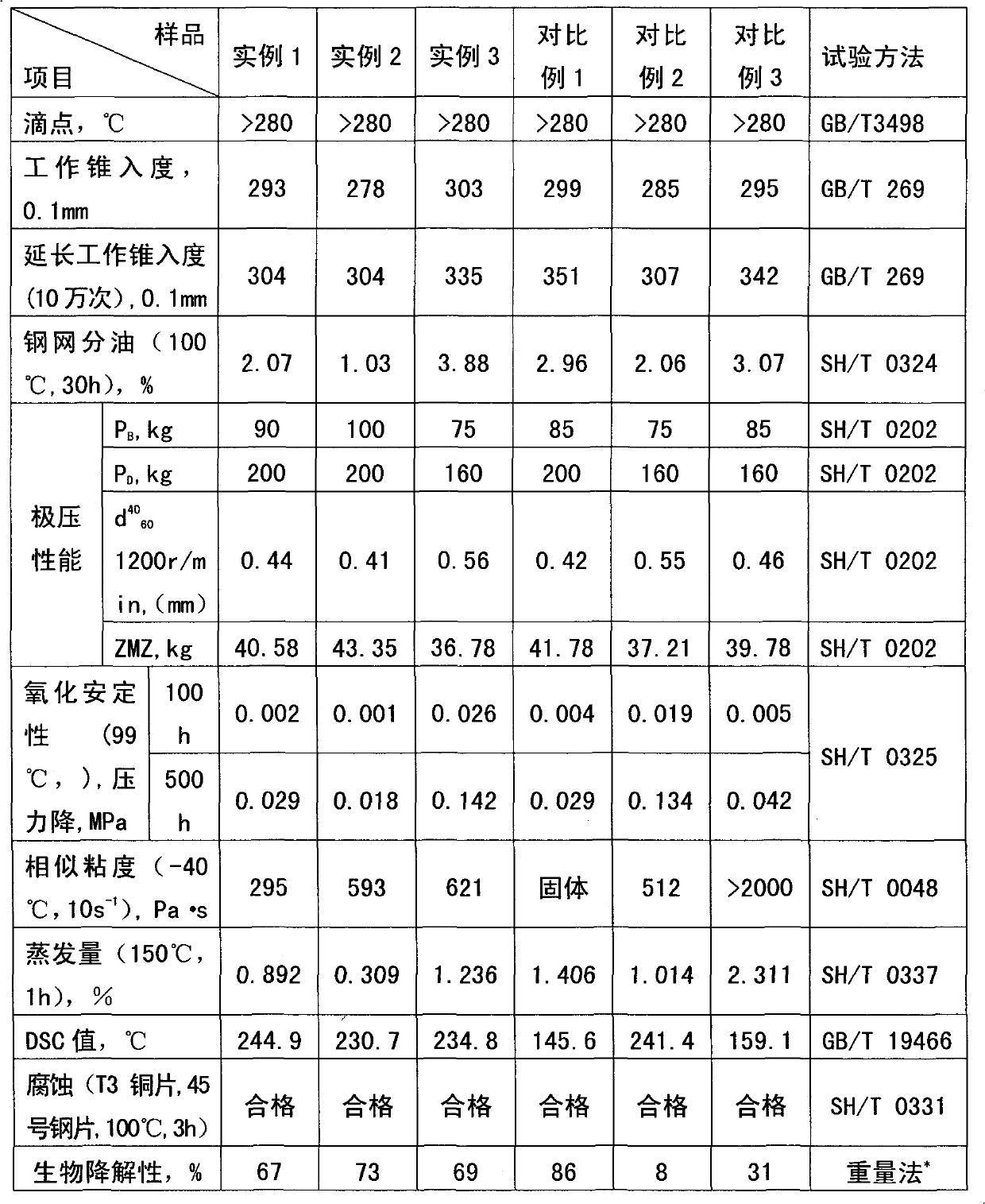

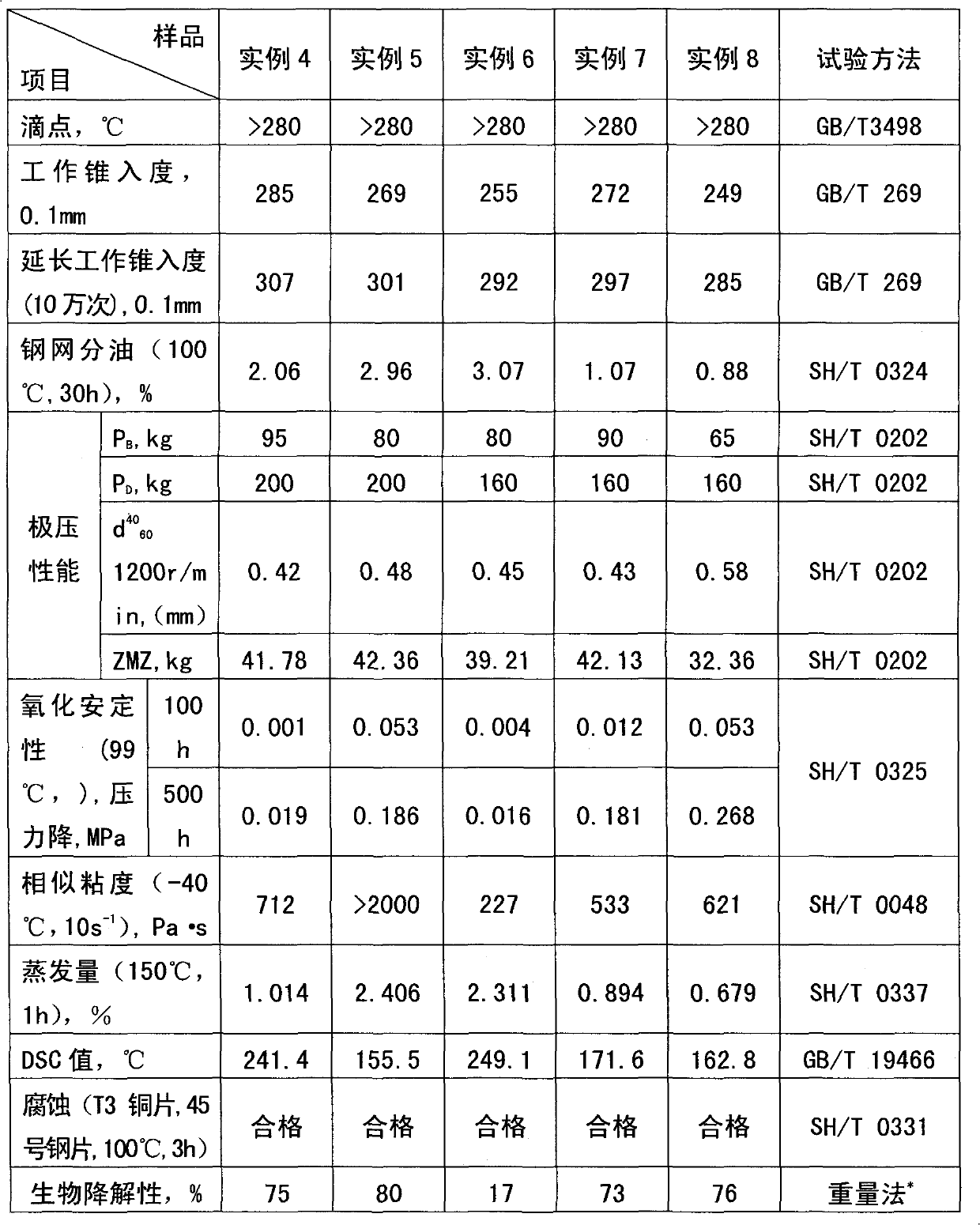

Examples

reference example 1

[0030] Weigh 100 ml of absolute ethanol, 1100 g of castor oil, and 40 g of tetrabutyl titanate into the reaction kettle, react for 8 hours under normal pressure and 40°C, and then distill the ethanol out in a vacuum distillation device , the pressure is -0.1MPa~-0.001MPa, the temperature is 25~60°C, and the modified vegetable oil can be obtained.

reference example 2

[0032] Weigh 100 ml of absolute ethanol, add 1100 g of peanut oil, and 25 g of tetrabutyl titanate into the reaction kettle, react for 6 hours under normal pressure and 60°C, and then distill the ethanol out in a vacuum distillation device, namely Modified vegetable oils are available.

reference example 3

[0034] Weigh 100 milliliters of absolute ethanol, 1100 grams of rapeseed oil, and 40 grams of tetrabutyl titanate into the reaction kettle of the reaction distillation device. The modified vegetable oil can be obtained by distilling ethanol out under reduced pressure in vacuum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com