Biodegradable unsaturated polyurethane material and preparation method thereof

A polyurethane material and unsaturated technology, applied in the field of biomedical materials, can solve the problems of difficult and effective modification of medical degradable polyurethane materials, and achieve the effects of excellent biodegradability, efficient reaction sites, and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

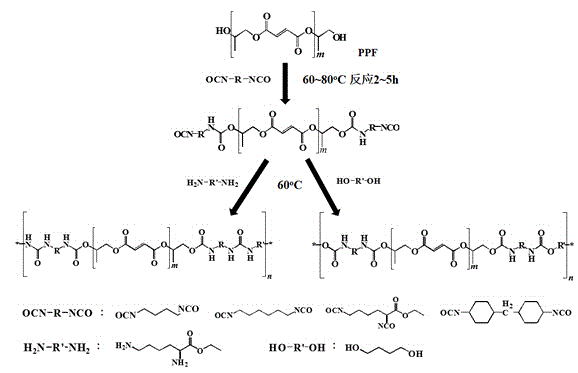

Method used

Image

Examples

Embodiment 1

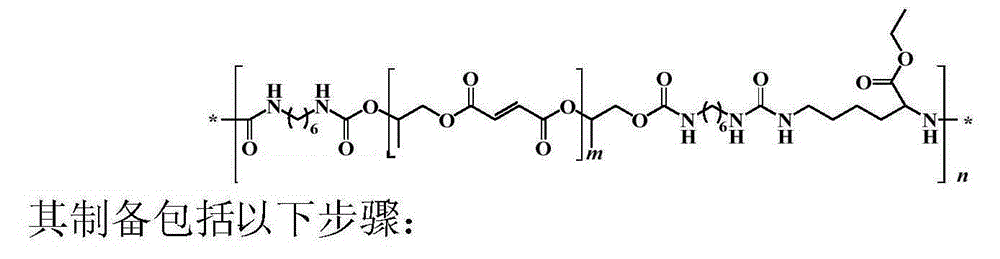

[0024] Biodegradable unsaturated polyurethane material (PPFU / HDI 1.6+Lys-OMe), including a soft segment and a hard segment, the soft segment is unsaturated polyester polyol polytrimethylene fumarate PPF, the hard segment It is an aliphatic isocyanate HDI and a small molecule diamine chain extender Lys-OMe.

[0025] has the following structure.

[0026]

[0027] PPF with a number-average molecular weight of 1000 was formulated into a polytrimethylene fumarate solution with a mass fraction of 30%. According to the ISO 2554-1974 method, the molar number of hydroxyl groups in the solution was determined to be 14.68 mmol.

[0028] Take the above-mentioned PPF toluene solution and put it into a dry three-necked flask, reduce the pressure at 110°C for 1 hour, and remove the solvent toluene and residual water. Add solvent anhydrous dioxane 30mL to re-dissolve, add 1.9752g hexamethylene diisocyanate (HDI), 0.03mmol catalyst dibutyltin dilaurate, react at 70°C for 3h under nitrogen ...

Embodiment 2

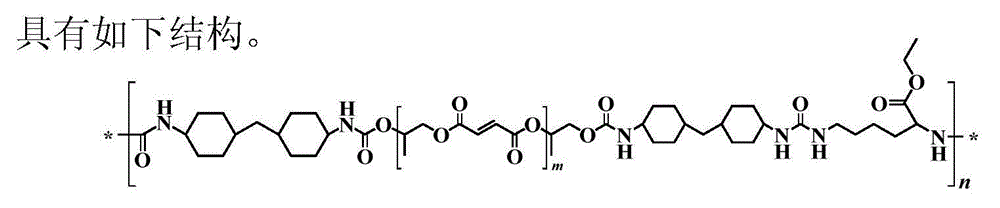

[0032] Biodegradable unsaturated polyurethane material (PPFU / HMDI 1.6+Lys-OMe), including soft segment and hard segment, the soft segment is unsaturated polyester polyol polytrimethylene fumarate PPF, the hard segment It is aliphatic isocyanate HMDI and small molecule diamine chain extender Lys-OMe.

[0033]

[0034] Its preparation includes the following steps:

[0035] PPF with a number average molecular weight of 1000 was formulated into a polytrimethylene fumarate solution with a mass fraction of 30%. According to the ISO 2554-1974 method, the molar number of hydroxyl groups in the solution was determined to be 14.68 mmol.

[0036] Take the above-mentioned PPF toluene solution and put it into a dry three-necked flask, distill under reduced pressure at 110°C for 1 hour, and remove the solvent toluene and residual water. Add solvent anhydrous dioxane 30mL to redissolve, add 3.0810g 4,4'-dicyclohexylmethane diisocyanate (HMDI), 0.03mmol catalyst dibutyltin dilaurate, reac...

Embodiment 3

[0039] Biodegradable unsaturated polyurethane material (PPFU / LDI 1.6+Lys-OMe), including a soft segment and a hard segment, the soft segment is unsaturated polyester polyol polytrimethylene fumarate PPF, the hard segment It is an aliphatic isocyanate LDI and a small molecule diamine chain extender Lys-OMe.

[0040] has the following structure.

[0041]

[0042] Its preparation includes the following steps:

[0043] PPF with a number-average molecular weight of 1000 was formulated into a polytrimethylene fumarate solution with a mass fraction of 30%. According to the ISO 2554-1974 method, the molar number of hydroxyl groups in the solution was determined to be 14.68 mmol.

[0044] Take the above-mentioned PPF toluene solution and put it into a dry three-necked flask, distill under reduced pressure at 110°C for 1 hour, and remove the solvent toluene and residual water. Add solvent anhydrous dioxane 30mL to redissolve, add 2.6568g L-lysine diisocyanate (LDI), 0.03mmol cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com