Polylactic acid foam material and preparation method thereof

A foam material, polylactic acid technology, applied in the field of foam materials, can solve problems such as environmental pollution, and achieve the effect of good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a preparation method of the polylactic acid foam material, comprising:

[0035] Stir the following raw materials and then extrude and foam to obtain a polylactic acid foam material;

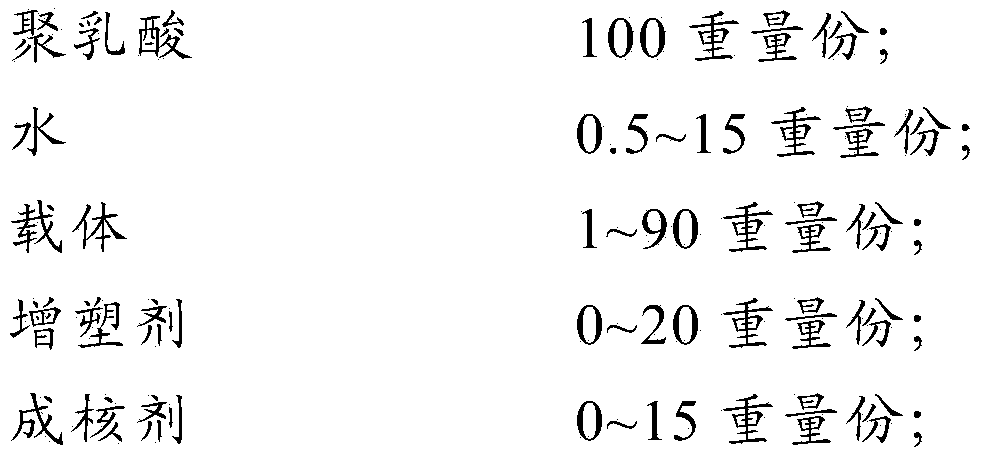

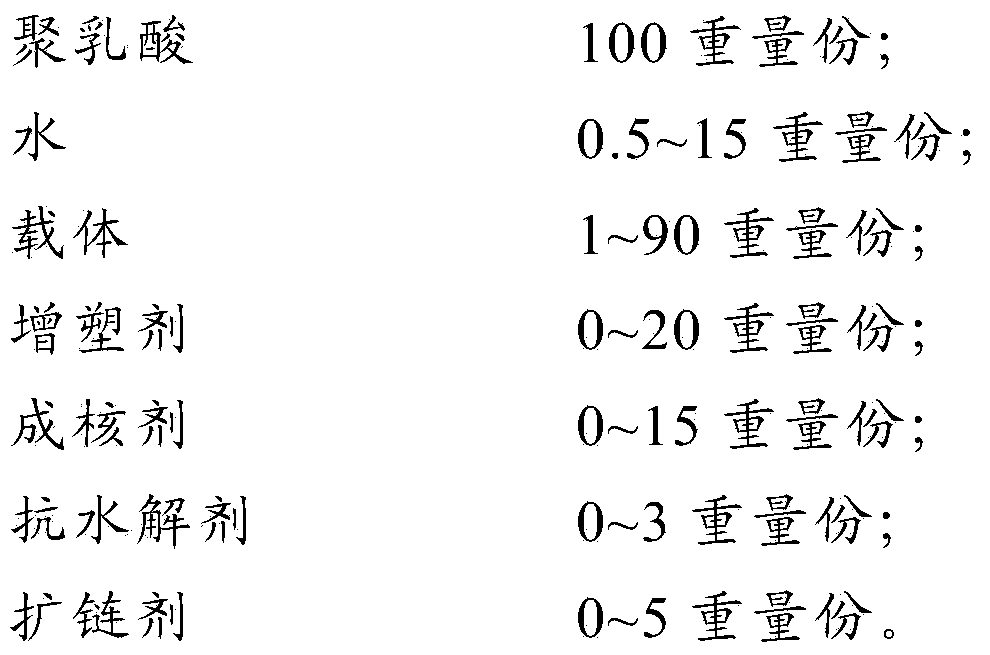

[0036]

[0037] According to the present invention, the polylactic acid foam material is directly prepared by direct extrusion. In the process of preparing polylactic acid foam, first mix polylactic acid, water, carrier, plasticizer, nucleating agent, anti-hydrolysis agent and chain extender, and then stir. The stirring time is preferably 3 to 5 minutes, so that the above Raw materials can be mixed evenly.

[0038]After the above materials are stirred, the obtained mixture is directly extruded and foamed to obtain a polylactic acid foam material. The present application preferably extrudes foaming in a twin-screw extruder. During the process of extruding and foaming, the heating system of the twin-screw extruder is divided into different areas, so ...

Embodiment 1

[0043] Weigh each component according to the following parts by weight: 100 parts of polylactic acid with a weight-average molecular weight of 50,000, 0.5 part of water, and 1 part of starch. Extrude and foam to obtain polylactic acid foam; the temperature range of the extrusion foaming system is: Zone 1: 50°C, Zone 2: 50°C, Zone 3: 100°C, Zone 4: 120°C, Zone 5: 130°C , Zone six: 130°C, zone seven: 120°C, the temperature of the die head is 100°C. The expansion ratio of the polylactic acid foam prepared in this example is 1 times, and the compressive strength is 10 MPa.

Embodiment 2

[0045] Weigh each component according to the following parts by weight: 100 parts of polylactic acid with a weight average molecular weight of 200,000, 15 parts of water, 90 parts of starch, 20 parts of dioctyl phthalate, 15 parts of zinc oxide, carbodiimide 3 parts, 5 parts of toluene diisocyanate. Stir the above components in the mixer for 3 minutes, then directly extrude and foam on the twin-screw to obtain polylactic acid foam; the temperature range of the extrusion foaming system is: Zone 1: 90°C, Zone 2: 100°C ℃, zone 3: 160°C, zone 4: 190°C, zone 5: 190°C, zone 6: 180°C, zone 7: 150°C, and the die head temperature is 150°C. The expansion ratio of the polylactic acid foam material prepared in this example is 40 times, and the compressive strength is 0.05 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com