Molten steel vacuum refining system based on mechanical pump group

A vacuum refining and mechanical pump technology, applied in the field of vacuum refining of molten steel, can solve the problems of environmental pollution, high energy consumption, overflowing slag and steel, etc., and achieve the effects of avoiding production safety accidents, reducing production costs, and preventing steel slag emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in combination with specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

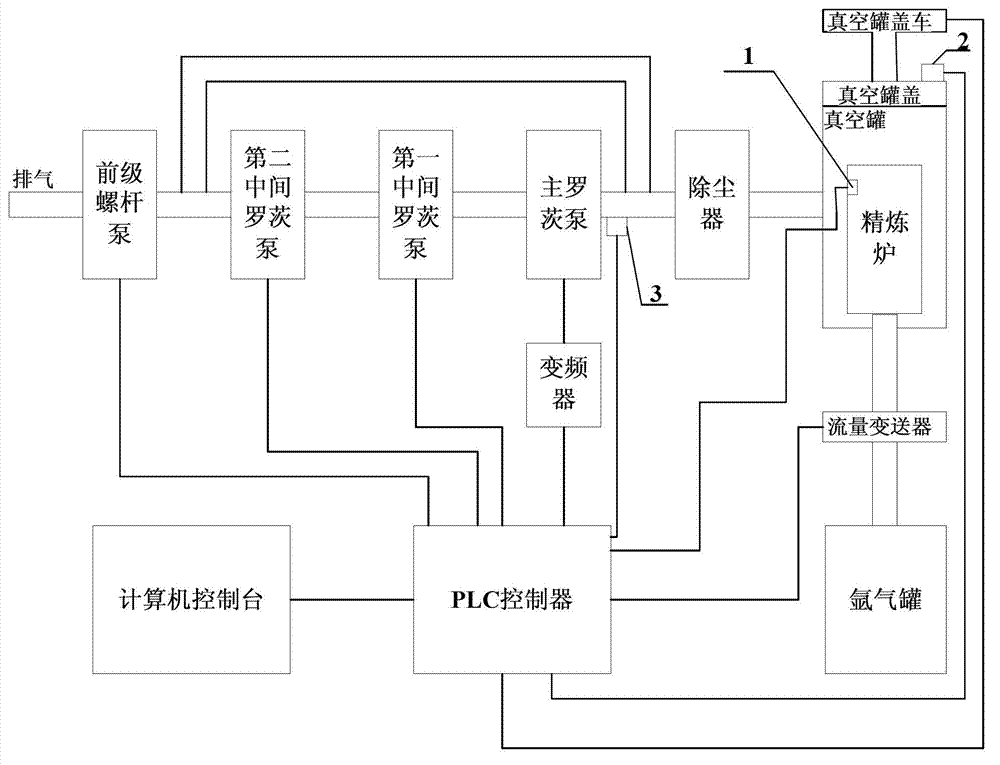

[0017] The molten steel vacuum refining system based on mechanical pump group of the present invention, see figure 1 , including a vacuum tank, a dust remover, a Roots pump group and a backing screw pump connected in turn through an outlet pipeline; the dust collector is also directly connected to the backing screw pump through a pipeline; the bottom of the vacuum tank is connected with argon system; the Roots pump group includes a main Roots pump, a first intermediate Roots pump and a second intermediate Roots pump, the molten steel vacuum refining system also includes a controller, the first interm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com