Method for separation and purification of fluorescent grade yttrium oxide and europium oxide from waste phosphor powder

A technology of yttrium europium oxide and fluorescent powder, which is applied in the field of environmental protection and comprehensive resource recycling, can solve the problems of complex process, complicated process, and secondary pollution of the environment, and achieve the effect of simple process, wide sources and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

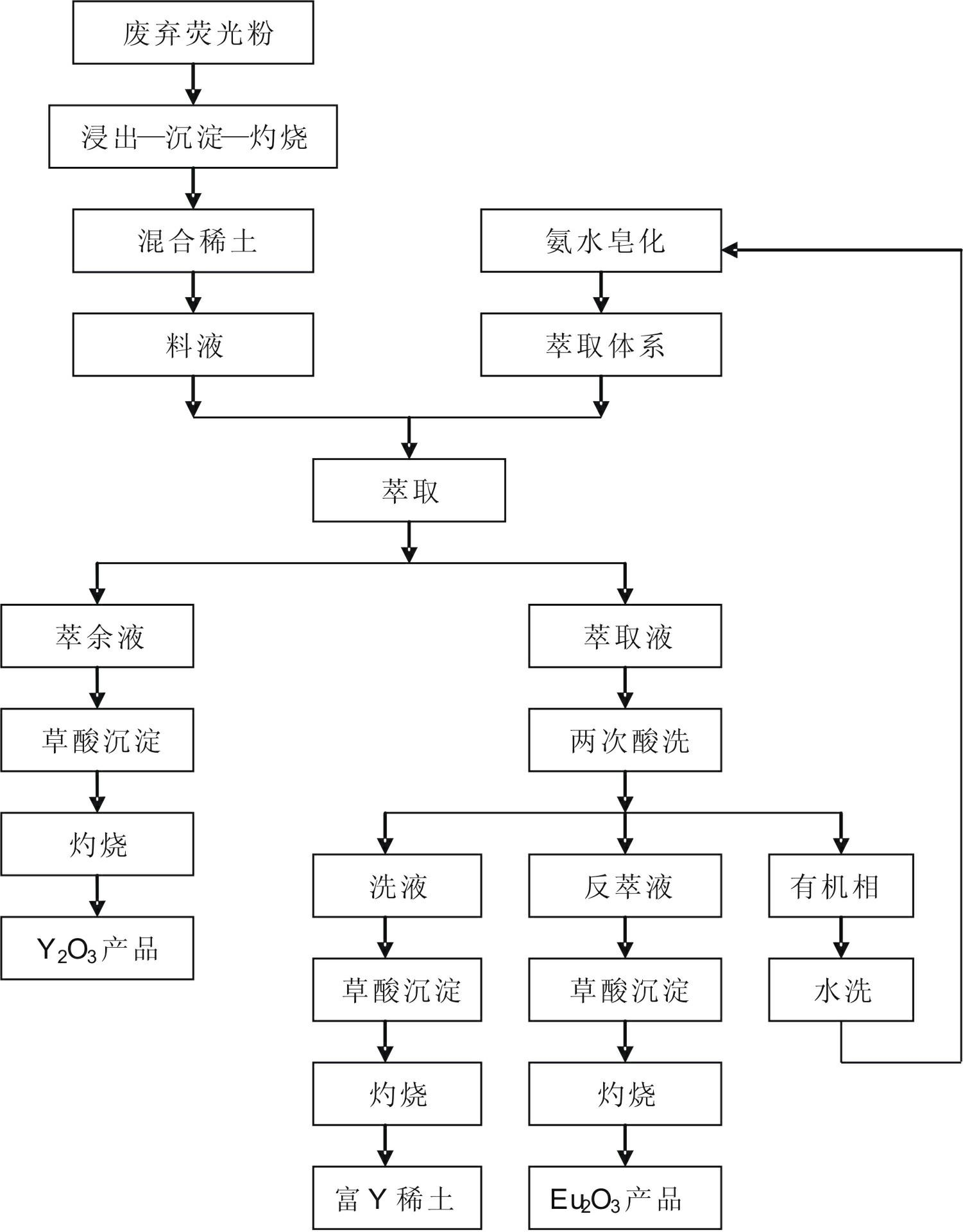

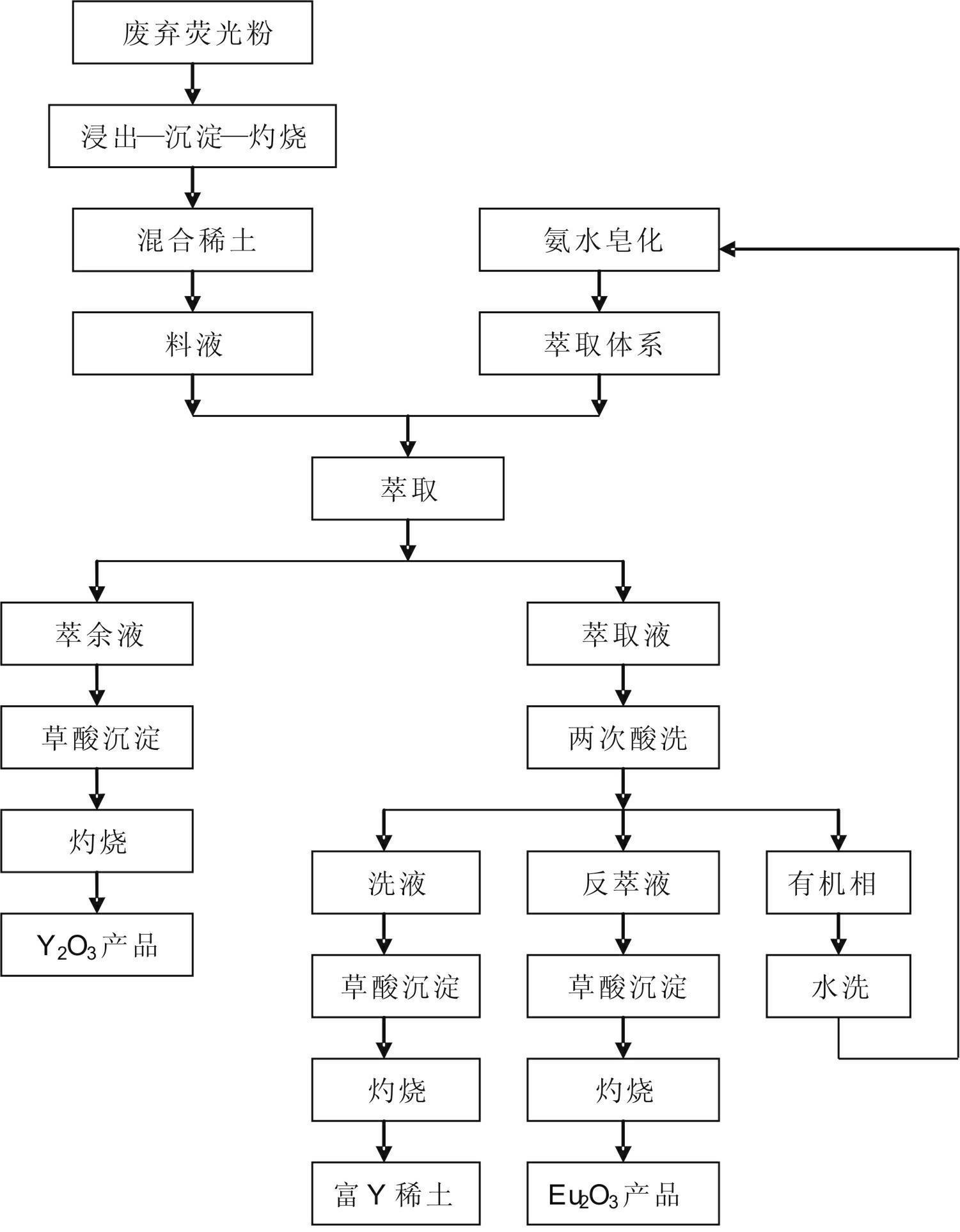

Method used

Image

Examples

Embodiment 1

[0050] Impurity removal experiment:

[0051] Take 20g of waste fluorescent powder, add 200ml of 4mol / L hydrochloric acid, rotate at 600rpm / min, add 0.4ml of 30% H 2 o 2 , temperature 60°C—80°C, leaching for 1-2h; put the leached solution into a centrifuge for solid-liquid separation to obtain a leaching solution, add 1:1 ammonia water to the leaching solution, adjust the pH value to 3.5-4, and then put it in a centrifuge machine for solid-liquid separation to obtain the filtrate that removes most of the aluminum, iron, silicon, magnesium and other impurities; heat the filtrate to boil, add 1:1 ammonia water, adjust the pH value to 7.8-9, and obtain rare earth hydroxide precipitation; Suction filtration while hot with quantitative filter paper, rinse the precipitate and the beaker with 20g / L ammonium chloride, then add the quantitative filter paper together with the precipitate to 10ml of concentrated hydrochloric acid to dissolve to obtain the rare earth enrichment solution; ...

Embodiment 2

[0057] Impurity removal experiment:

[0058] Take 20g of waste fluorescent powder, add 200ml of 4mol / L sulfuric acid, rotate at 600rpm / min, add 0.4ml of 30% H 2 o 2 , temperature 60°C—80°C, leaching for 1-2h; put the leached solution into a centrifuge for solid-liquid separation to obtain a leaching solution, add 1:1 ammonia water to the leaching solution, adjust the pH value to 3.5-4, and then put it in a centrifuge machine for solid-liquid separation to obtain the filtrate that removes most of the aluminum, iron, silicon, magnesium and other impurities; heat the filtrate to boil, add 1:1 ammonia water, adjust the pH value to 7.8-9, and filter to obtain rare earth hydroxides Precipitate; use quantitative filter paper to filter while it is hot, rinse the precipitate and beaker with 20g / L ammonium chloride, then add the filter paper together with the precipitate to 10ml of concentrated sulfuric acid to dissolve the rare earth enrichment solution; then add 200ml of boiling wate...

Embodiment 3

[0064] Impurity removal experiment:

[0065] Take 20g of waste fluorescent powder, add 200ml of 4mol / L nitric acid, rotate at 600rpm / min, add 0.4ml of 30% H 2 o 2 , temperature 60°C—80°C, leaching for 1-2h; put the leached solution into a centrifuge for solid-liquid separation to obtain a leaching solution, add 1:1 ammonia water to the leaching solution, adjust the pH value to 3.5-4, and then put it in a centrifuge machine for solid-liquid separation to obtain the filtrate that removes most of the aluminum, iron, silicon, magnesium and other impurities; heat the filtrate to boil, add 1:1 ammonia water, adjust the pH value to 7.8-9, and filter to obtain rare earth hydroxides Precipitate; use quantitative filter paper to filter while it is hot, rinse the precipitate and beaker with 20g / L ammonium chloride, then add the filter paper together with the precipitate to 10ml of concentrated nitric acid to dissolve the rare earth enrichment solution; then add 200ml of boiling water to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com