Modified 4Cr5MoSiV1 hot work die steel and preparation method thereof

A modification technology for hot work die steel, which is applied in the direction of metal processing equipment, etc., can solve the problems of hot work dies such as poor service conditions, poor secondary hardening ability, and small heat treatment deformation, so as to increase the yield of rare earths and reduce branches. Effect of crystal segregation and improvement of as-cast structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

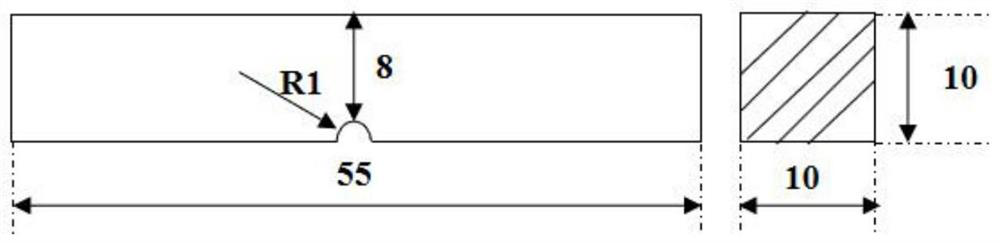

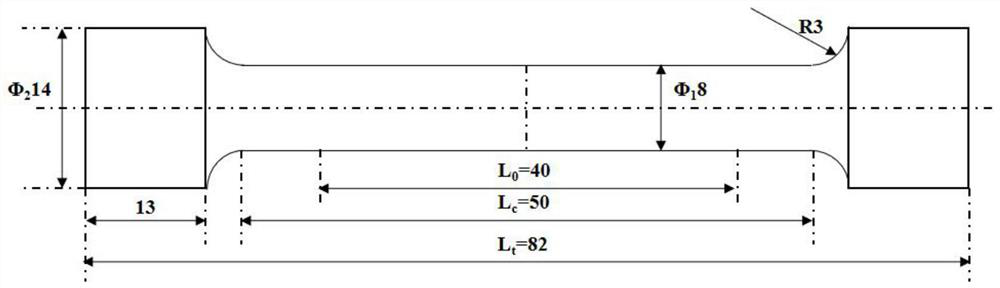

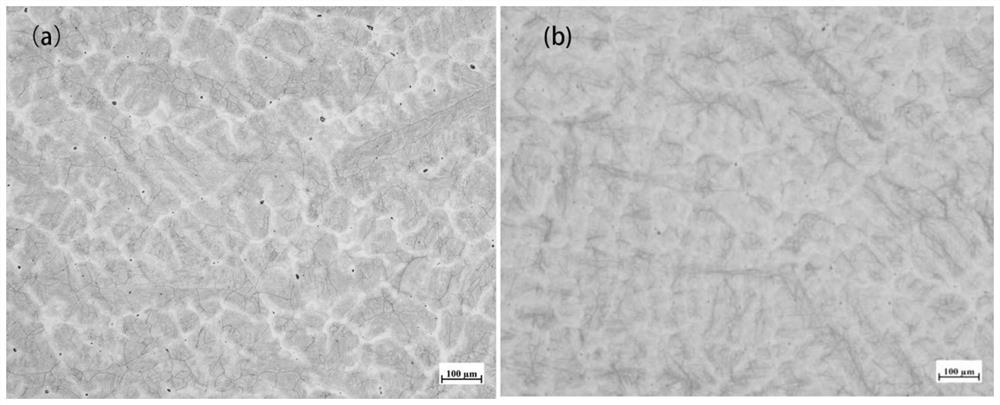

[0039] This embodiment provides a method for preparing a modified 4Cr5MoSiV1 hot work die steel, comprising the following steps:

[0040] S1, according to the following weight percentages, weigh each preparation raw material respectively:

[0041] C: 0.35%, Si: 1.18%, Mn: 0.46%, Cr: 4.88%, Mo: 1.57%, V: 1.19%, cerium-iron alloy 0.3%, and the balance is Fe.

[0042] S2, first place the weighed Fe, Cr, Mo, V in a vacuum furnace, smelt at 1500°C until melting, then add the weighed Si, C, keep it at 1650°C for 5min, then add the weighed Continue to smelt good rare earth alloys, control the residual amount of rare earth elements in the steel to 0.018%, and control the oxygen content in the steel to 20ppm;

[0043] S3, weigh Al according to 0.1% of the total amount of each preparation raw material, and add it into the vacuum furnace after S2 smelting, control the temperature at 1500 ° C for 5 minutes, and then cast it under the protection of argon to ensure that the oxygen in the s...

Embodiment 2

[0050] This embodiment provides a method for preparing a modified 4Cr5MoSiV1 hot work die steel, comprising the following steps:

[0051] S1, according to the following weight percentages, weigh each preparation raw material respectively:

[0052] C: 0.32%, Si: 0.8%, Mn: 0.2%, Cr: 4.75%, Mo: 1.10%, V: 0.8%, cerium-iron alloy 0.1%, and the balance is Fe.

[0053] S2, first place the weighed Fe, Cr, Mo, V in a vacuum furnace, smelt at 1550°C until melting, then add the weighed Si, C, keep it at 1600°C for 7min, then add the weighed Continue to smelt good rare earth alloys, control the residual amount of rare earth elements in the steel to 0.001%, and control the oxygen content in the steel to 15ppm;

[0054] S3, weigh Al according to 0.05% of the total amount of each preparation raw material, and add it into the vacuum furnace after S2 smelting, control the temperature at 1450 ° C for 3 minutes, and then cast it under the protection of argon to ensure that the oxygen in the ste...

Embodiment 3

[0061] This embodiment provides a method for preparing a modified 4Cr5MoSiV1 hot work die steel, comprising the following steps:

[0062] S1, according to the following weight percentages, weigh each preparation raw material respectively:

[0063] C: 0.45%, Si: 1.2%, Mn: 0.5%, Cr: 5.50%, Mo: 1.75%, V: 1.2%, cerium-iron alloy 0.5%, and the balance is Fe.

[0064] S2, first place the weighed Fe, Cr, Mo, V in a vacuum furnace, smelt at 1600°C until melting, then add the weighed Si, C, keep it at 1700°C for 7min, then add the weighed Continue to smelt good rare earth alloys, control the residual amount of rare earth elements in the steel to 0.02%, and control the oxygen content in the steel to 18ppm;

[0065] S3, weigh Al according to 0.15% of the total amount of each preparation raw material, and add it into the vacuum furnace after S2 smelting, control the temperature at 1550 ° C for 7 minutes, and then cast it under the protection of argon to ensure that the oxygen in the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com