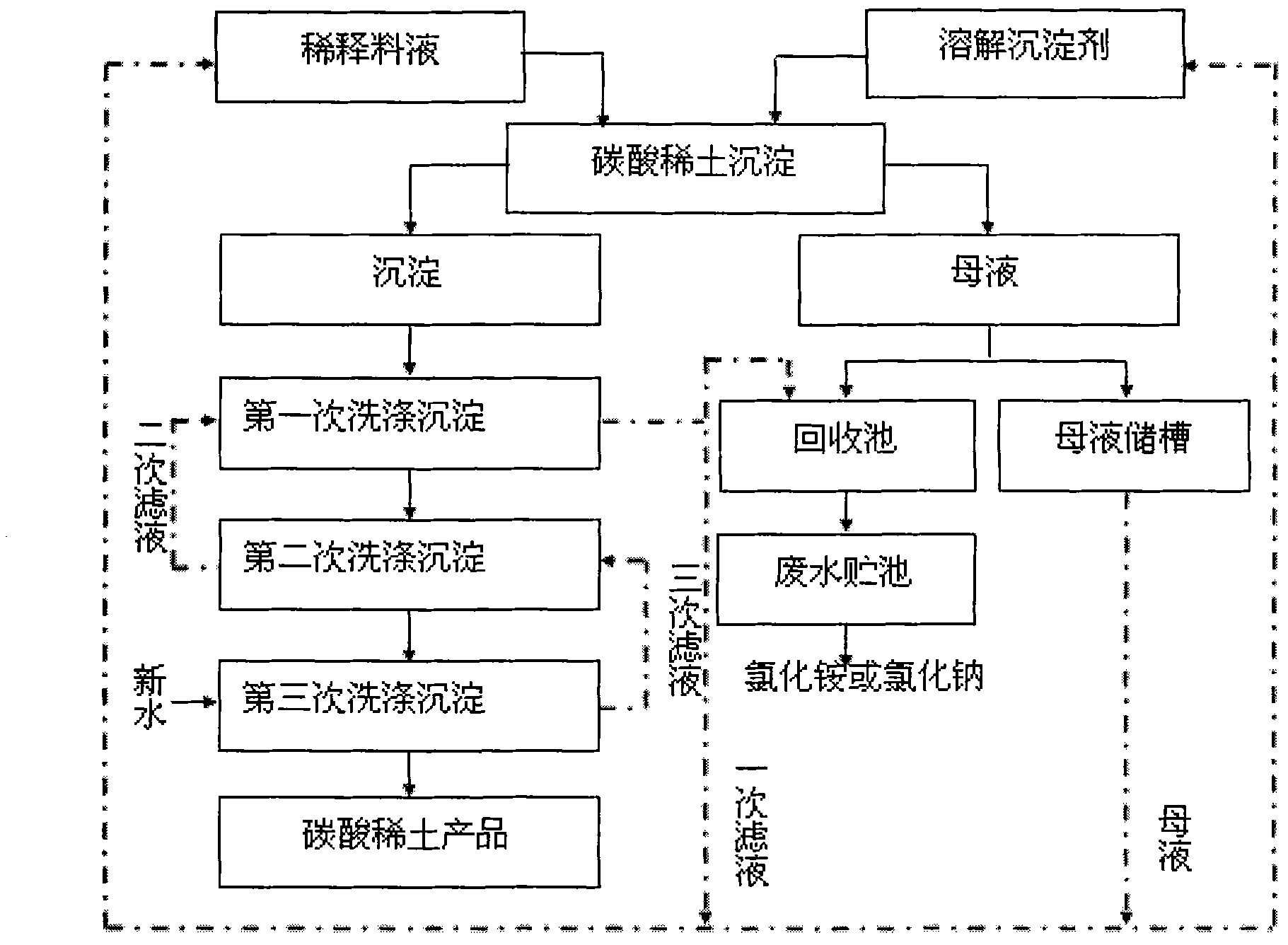

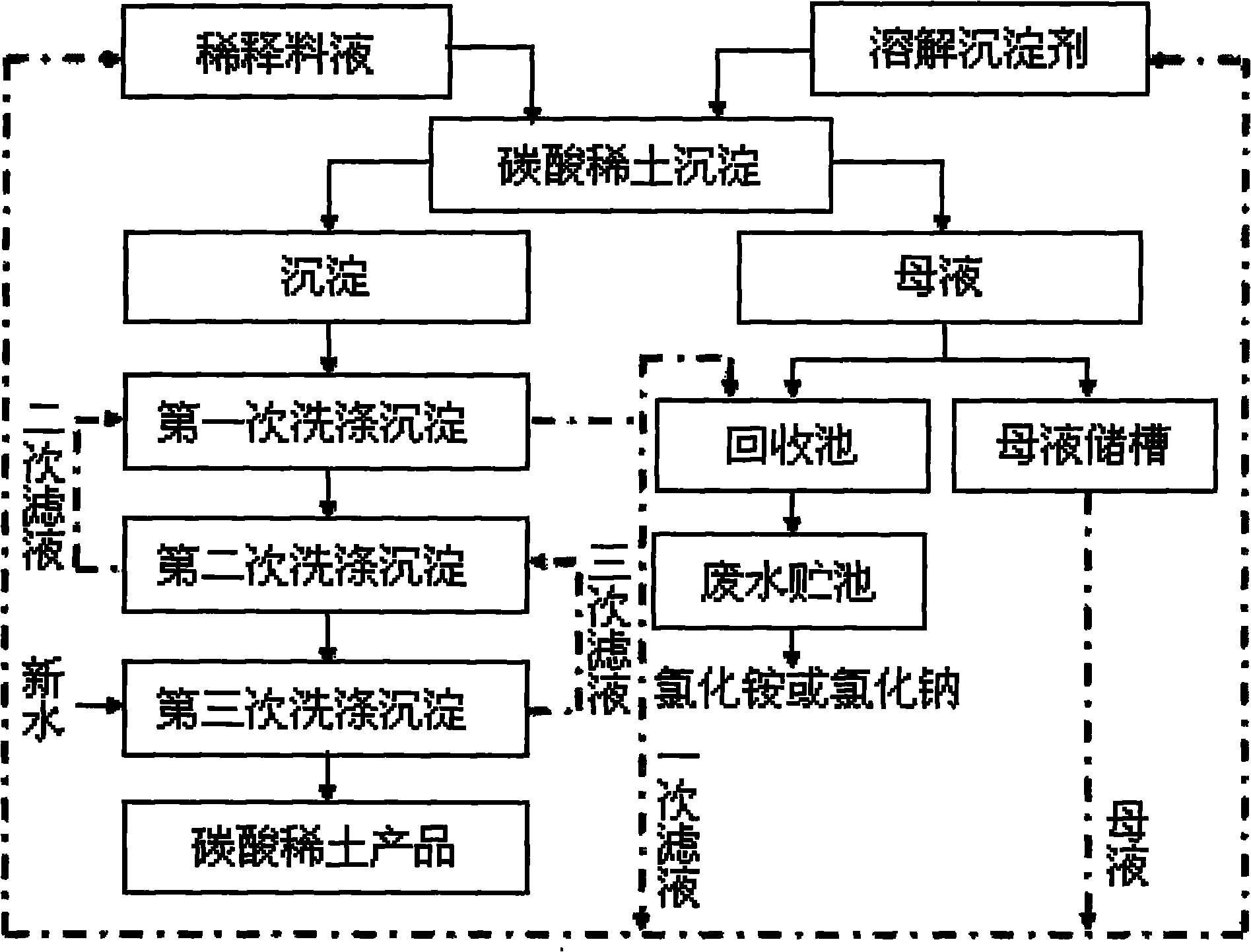

Self recycling method of waste water in rare earth carbonate precipitation

A rare earth carbonate self-recycling technology, applied in the fields of rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as unacceptable by enterprises, environmental pollution, and large equipment needs, so as to improve the effective utilization rate and improve the rare earth Yield, the effect of reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Feed liquid: the mixed rare earth chloride is extracted and separated by two stages of neodymium samarium and cerium praseodymium, and the residual liquid of the cerium praseodymium extraction and separation section is a praseodymium neodymium chloride solution, which is used as a praseodymium neodymium carbonate precipitation liquid, and its composition includes PR 6 o 11 Content is 25%, Nd 2 o 3 The content is 75%, the rare earth concentration is 1.27mol / L, pH=2, and the precipitation of praseodymium and neodymium carbonate is 5700 tons per year.

[0018] Precipitating agent: ammonium bicarbonate solution.

[0019] The concentration of praseodymium neodymium chloride solution before the precipitation of praseodymium carbonate is 1.27mol / L, and the solution volume is 40M 3 / day, use 50M 3 4 settling tanks, each settling 2 times a day, a total of 8 settling; in one 50M 3 Add praseodymium and neodymium chloride solution 5M in the precipitation tank 3 , join 21.5M...

Embodiment 2

[0021] Raw material: The rare earth chloride solution is extracted and separated by two stages of gadolinium, terbium and europium and gadolinium, and the back-extracted raffinate in the europium and gadolinium extraction and separation stage is a gadolinium chloride solution, which is used as a gadolinium carbonate precipitation feed solution. The rare earth concentration is 1.23mol / L, and the pH= 2. The precipitation of gadolinium carbonate is 300 tons / year.

[0022] Precipitating agent: sodium carbonate solution.

[0023] The concentration of feed solution before gadolinium carbonate precipitation is 1.23mol / L, and the volume of feed solution is 2M 3 / day, use 12M 3 1 settling tank, settling once a day; add gadolinium chloride solution 2M to the settling tank 3 , adding 3.6M 3 Gadolinium carbonate precipitation wastewater dilutes the concentration of gadolinium chloride solution to 0.44mol / L, and the volume of gadolinium chloride solution is 5.6M 3 , heat the gadoliniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com