A device for improving the oxidation rate of NdFeB oxide material

An oxidizing material and oxidation rate technology, applied in the field of rotary kiln, can solve the problems of large auxiliary raw material and energy consumption, insufficient rare earth dissolution rate, increase in production cost, etc., to reduce labor intensity, increase economic benefits and market competitiveness, speed up The effect of production progress

Active Publication Date: 2017-08-22

中稀天马新材料科技股份有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, rotary kilns are usually used to process NdFeB waste. Due to the low oxidation rate, there are many problems in processing and production, such as: 1. The dissolution rate of rare earth is not enough, and the consumption of auxiliary raw materials and energy is large, resulting in production costs. Increase; 2. When filtering, the slag is not easy to filter; 3. Low production efficiency and high labor intensity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

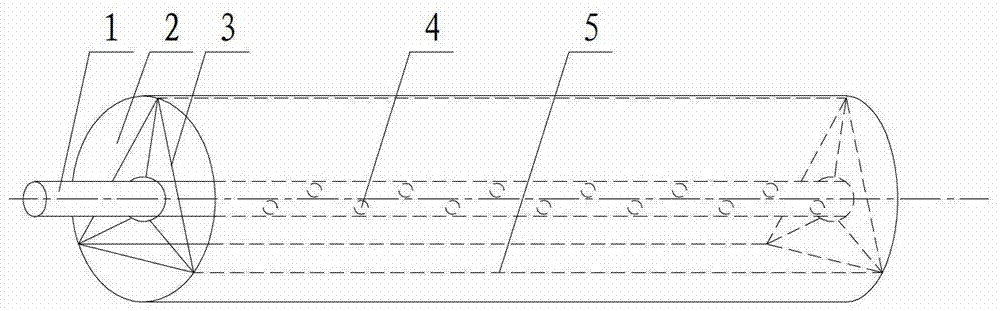

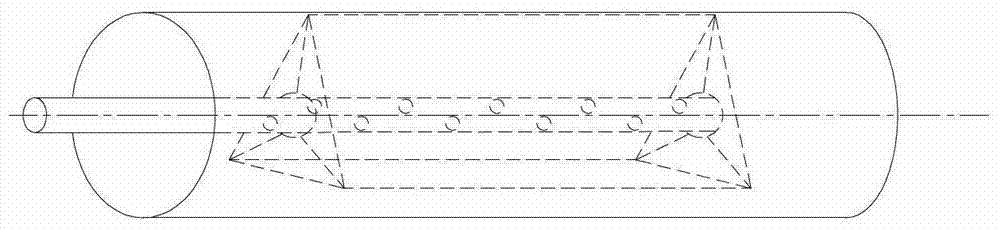

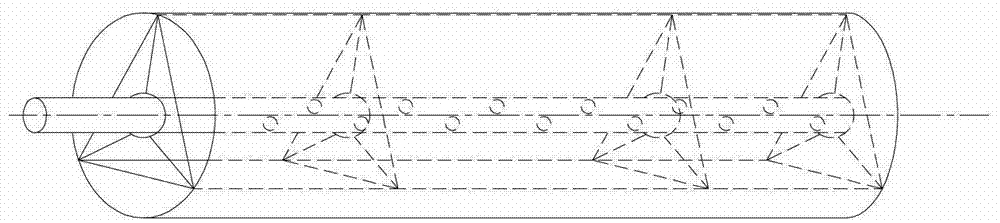

The invention relates to a device for increasing the oxidation rate of neodymium-iron-boron oxide materials, which comprises a rotary kiln, in which a stirrer and a ventilation pipe are placed through a mounting frame, and a plurality of air holes are formed on the ventilation pipe. The invention is a rotary kiln with simple structure, ingenious design, convenient disassembly and assembly, and safe use. The rotary kiln achieves the purpose of increasing the oxidation rate of the oxidizing material by increasing the stirring and oxygen content of the oxidizing material in the kiln body, thereby improving the oxidation rate. Rare earth yield of raw materials, saving auxiliary raw materials and energy, reducing production costs of enterprises and improving production efficiency.

Description

technical field [0001] The invention relates to the field of rotary kilns, in particular to a device for increasing the oxidation rate of NdFeB oxide materials. Background technique [0002] NdFeB is a high-end rare earth material, which contains a large amount of rare earth elements neodymium, iron and boron. At present, rotary kilns are usually used to process NdFeB waste. Due to the low oxidation rate, there are many problems in processing and production, such as: 1. The dissolution rate of rare earth is not enough, and the consumption of auxiliary raw materials and energy is large, resulting in production costs. 2. When filtering, the slag is not easy to filter; 3. The production efficiency is low and the labor intensity is high. Contents of the invention [0003] The purpose of the present invention is to overcome the deficiencies of the prior art, and provide a device with reasonable design and simple structure, which can increase the oxidation rate of NdFeB oxide m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F27B7/16F27B7/36C22B59/00C22B1/216

Inventor 林平郝宗华商成朋

Owner 中稀天马新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com