Vacuum smelting furnace and method for preparing high-purity metal ytterbium through one-time continuous reduction distillation

A vacuum smelting and metal technology, which is applied in the field of vacuum smelting furnace and one-time continuous reduction distillation to prepare high-purity metal ytterbium, which can solve the problems of high power consumption for secondary distillation, reduction of metal ytterbium yield, loss of rare earth metals, etc., and achieve overflow rate Low, lanthanum impurity reduction, effect of removing impurity entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

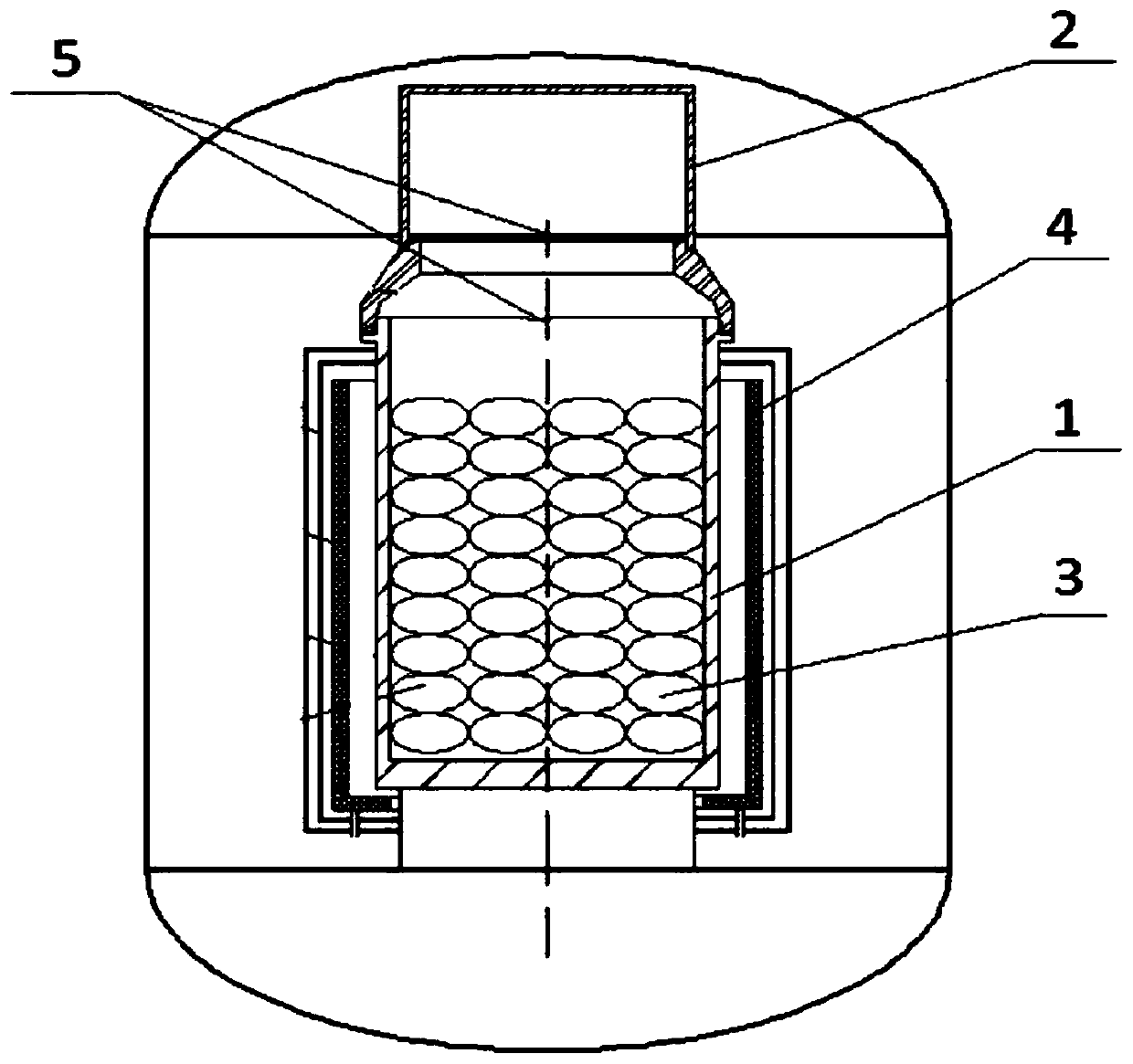

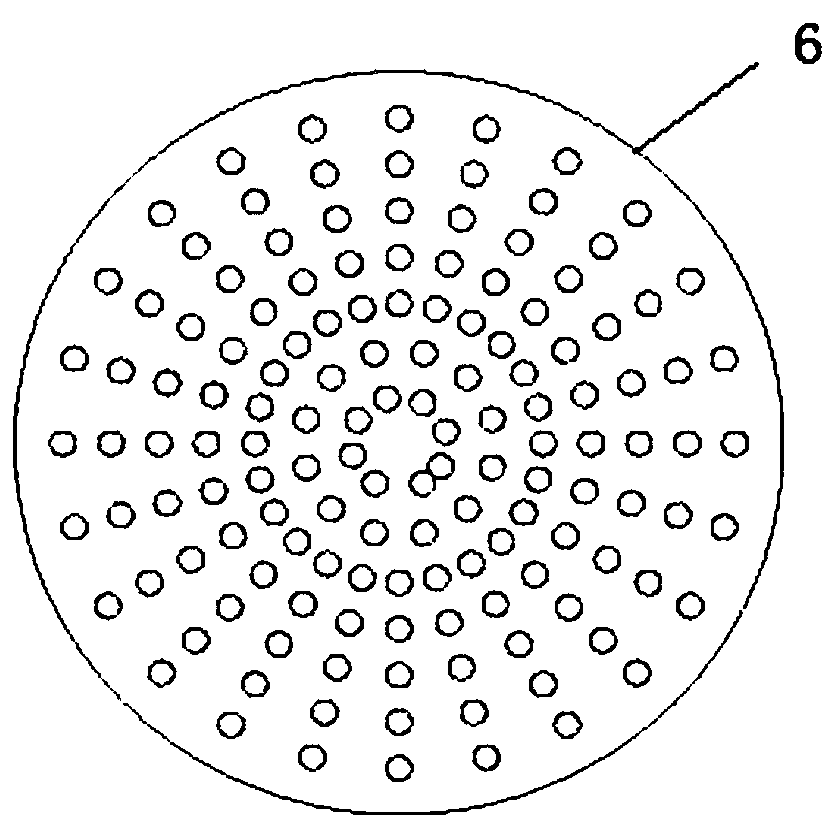

[0036]High-purity ytterbium oxide and lanthanum chips are mixed in a certain proportion, compacted, and loaded into a vacuum smelting furnace. Titanium plates with Ф6 round holes are respectively installed on the transition section between the material block and the metal receiver, and the receiver is sealed, and the vacuum is pumped to 10Pa. Heat up for 30 minutes to 500°C, hold for 120 minutes, heat up to 780°C, hold for 3 hours, heat up to 900°C for 30 minutes, hold for 3 hours, heat up to 1150°C for 30 minutes, hold for 7 hours; power off for 120 minutes to cool down to 600°C, turn off the mechanical pump, and flush with argon Let cool to room temperature.

[0037] The metal samples were taken out, and the compositional analysis results were as follows:

[0038] Y<0.00050, La0.00070, Ce0.00050, Pr<0.00050, Nd<0.00050, Sm<0.00050, Eu0.0010, Gd<0.00050, Tb<0.00050, Dy<0.00050, Ho<0.00050, Er<0.00050, Tm 0.00050, Lu<0.00050, Yb / RE99.99.

[0039] There are many kinds of rare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com