Patents

Literature

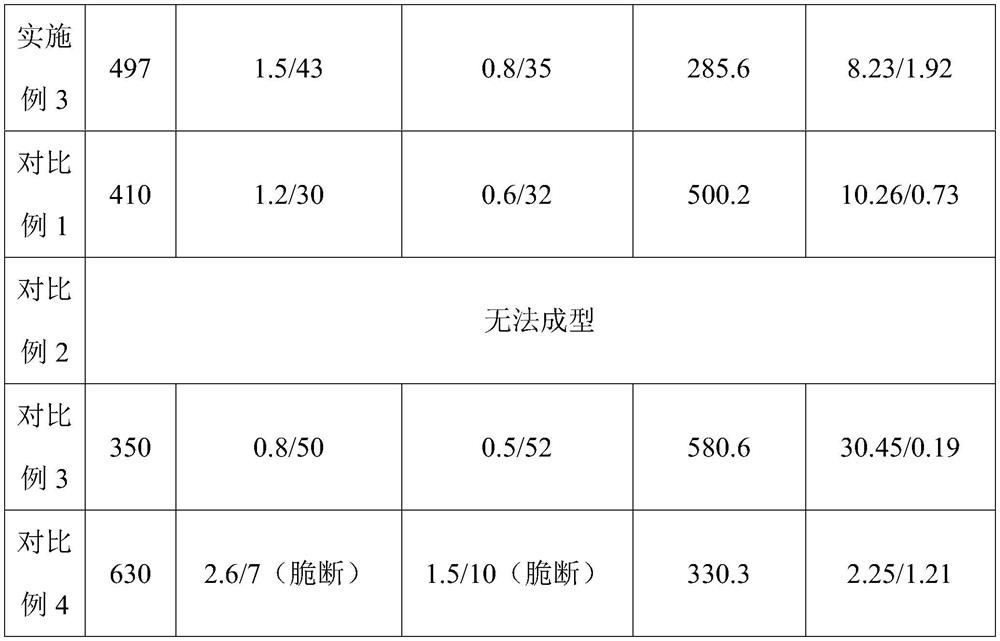

73 results about "Titanium molybdenum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molybdenum Alloys. Molybdenum is another critical alloying element for the titanium and superalloy industries. The ability of molybdenum to withstand extreme temperatures without significantly expanding or softening makes it useful in applications that involve intense heat.

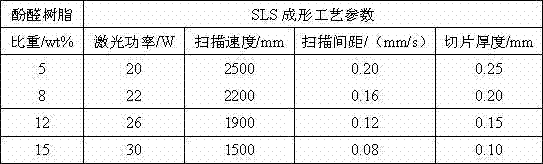

Method for preparing complexly shaped biomedical porous titanium molybdenum alloy implant body

InactiveCN102335742ADesign personalizationHigh dimensional accuracyIncreasing energy efficiencyProsthesisNatural boneMetallic materials

The invention provides a method for preparing a complexly shaped biomedical porous titanium molybdenum alloy implant body and belongs to the technical field of biomedical porous metallic material preparation. The method comprises the following steps of: taking a mixture of titanium and molybdenum metallic element powder and organic polymer powder as raw materials, and then preparing the biomedical porous titanium molybdenum alloy implant body by adopting the processes, such as three-dimensional modeling, selective laser-firing rapid forming, thermal de-greasing, vacuum sintering, and the like. The processing steps are simple, the period is short, the use ratio of materials is high, the cost is low, any complexly shaped porous titanium alloy implant body can be conveniently manufactured, and the method has efficiency and economic advantages in individual design and rapid manufacturing of the implant body. A titanium molybdenum alloy material prepared by using the method has the advantages that pore space is uniform, adjustment scopes of porosity, aperture ratio and aperture are wide, elasticity modulus and compression strength are in close proximity to natural bone, and the demand on biomechanical compatibility required by a biomedical material is met.

Owner:UNIV OF SCI & TECH BEIJING

Exhaust gas purification catalyst and method for production thereof

The invention realizes a catalyst which is hardly deteriorated even when volatile catalyst-poisoning compounds such as P and As are accumulated and which can reduce the rate of oxidation of SO2 to a level as low as a fraction of that of the catalyst in the prior art, and provides an exhaust gas purification catalyst which can maintain a high activity and a low rate of oxidation of SO2 for a long time even with any diversified coal, a method of producing the same, and an exhaust gas purification method using the same. Disclosed is an exhaust gas purification catalyst having a composition comprising oxides of titanium (Ti), molybdenum (Mo) and / or tungsten (W), vanadium (V) and bismuth (Bi), wherein the atomic ratio of Ti:(Mo and / or W):V is 75 to 98.9:1 to 0.1 to 10 and the atomic ratio of Bi / (Mo and / or W) is 0.1 to 0.8.

Owner:BABCOCK HITACHI KK

Method for smelting molybdenum titanium alloy

The invention discloses a method for smelting molybdenum titanium alloy, which comprises: adding 1 to 4 weight percent of molybdenum powder when mixing a granular or clastic titanium alloy raw material; and performing vacuum consumable electrode arc smelting for multiple times to obtain molybdenum titanium alloy cast ingots with uniform components. In the invention, the molybdenum powder is used as the raw material and added into the molybdenum titanium alloy; and as an intermediate process of preparing the molybdenum powder into molybdenum bars by powder metallurgy and subsequent deformationprocessing techniques first and then forming titanium and molybdenum by vacuum consumable electrode arc smelting of the molybdenum bars and titanium sponge or an intermediate process of forming an aluminum molybdenum alloy with molybdenum and aluminum by an aluminothermic process is not adopted, the production cost of the molybdenum titanium alloy is reduced considerably, the molybdenum titanium alloy cast ingots which are uniform in components and free from segregation and impurities can be obtained, and considerable economic benefit can be created.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

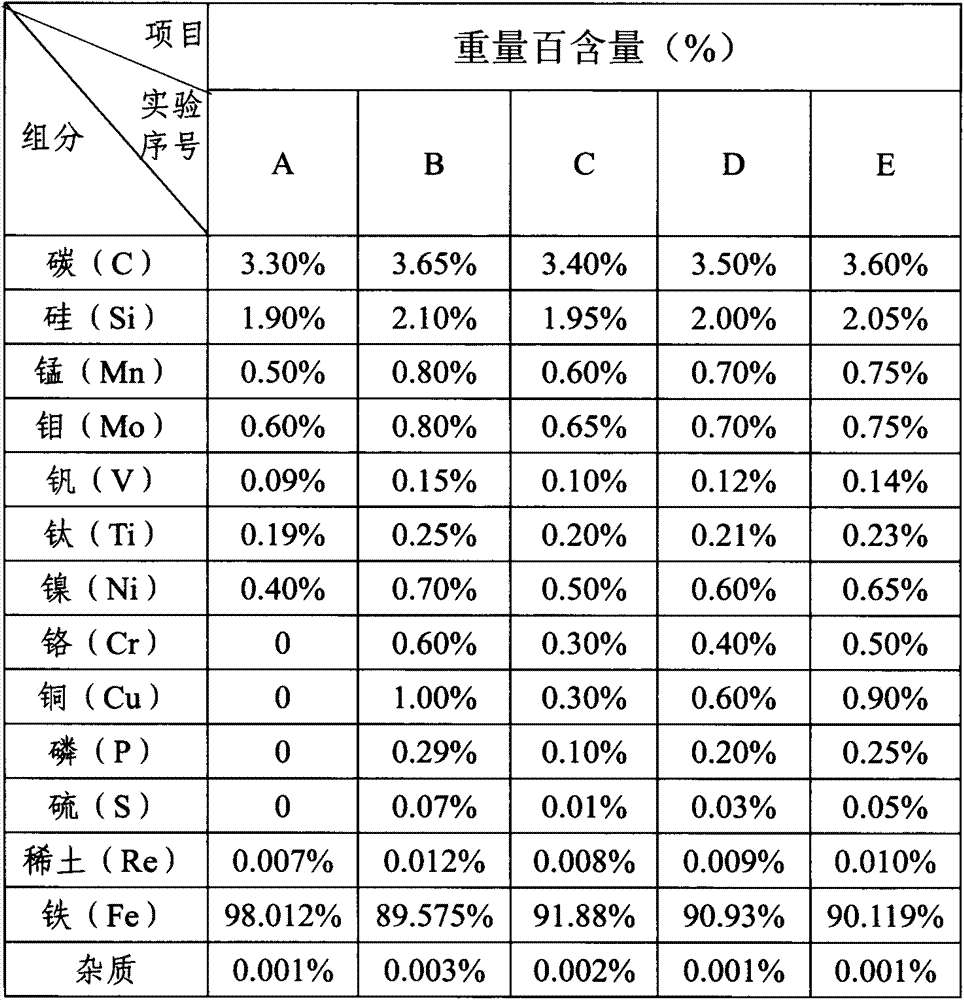

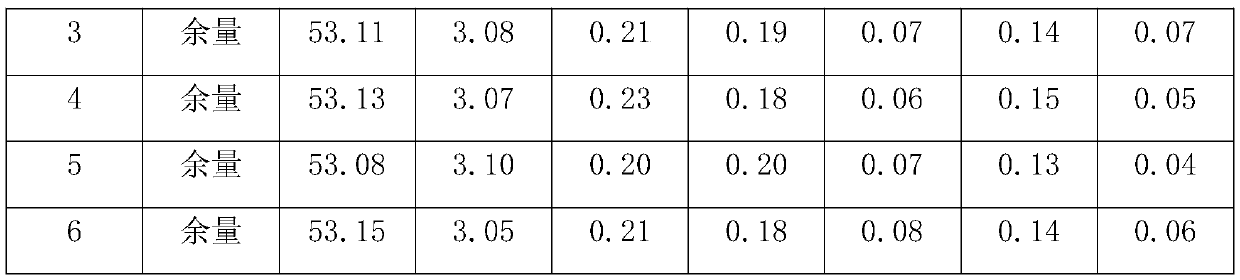

Glass mold material for small-hole blowing and pressing and preparation method thereof

The invention discloses a glass mold material, which is high in performance and applicable to small-hole blowing and pressing, and a preparation method thereof. The glass mold material for small-hole blowing and pressing comprises the following chemical components by mass percent: 3.30-3.65% of carbon, 1.90-2.10% of silicon, 0.50-0.80% of manganese, 0.60-0.80% of molybdenum, 0.09-0.15% of vanadium, 0.19-0.25% of titanium, 0.40-0.70% of nickel, no more than 0.60% of chromium, no more than 1.00% of copper, less than 0.30% of phosphorus, less than 0.08% of sulphur, 0.007-0.012% of rare earth, and the balance being iron and normal trace impurity. The material overcomes the defects of the material performance of a bottle-making machine under high-speed rotation besides the advantages of the traditional vanadium-titanium-molybdenum cast-iron glass mold material, and further improves the hardness and the toughness of the material, so that the material has better abrasive resistance, heat resistance and high-temperature oxidation resistance, and the glass mold prepared from the material has better stability, and more accords with the demands of a small-hole blowing and pressing process, so as to meet the lightweight needs of a glassware factory.

Owner:CHANGSHU WEIHENG MOLD MFG

Honeycomb low-temperature SCR denitration catalyst and preparation method thereof

ActiveCN109529813ASolve difficult moldingCalcination temperature is lowDispersed particle separationCatalyst activation/preparationPolyethylene oxideWater vapor

The invention relates to a honeycomb low-temperature SCR denitration catalyst and a preparation method thereof, and belongs to the technical field of flue gas denitration. The preparation method comprises the following steps: A, mixing: 100 parts by weight of titanium-molybdenum powder, 8-20 parts by weight of carboxymethyl cellulose, 5-10 parts by weight of polyethylene oxide, 5-7.5 parts by weight of silicon dioxide powder, 5-7.5 parts by weight of silica sol, 7-18 parts by weight of wood pulp, 25-50 parts by weight of glass fiber, 50-80 parts by weight of deionized water, 5-15 parts by weight of an ammonium metavanadate solution, 10-20 parts by weight of an ammonium metatungstate solution, 30-55 parts by weight of ammonia water and 10-20 parts by weight of lactic acid are added into a mixer to be fully mixed; water vapor in the mixer is pumped after the mixing, and the molybdenum content of the titanium-molybdenum powder is greater than or equal to 7%; B, molding; C, drying; and D,calcination. By the preparation method, the energy consumption is reduced, and the denitration efficiency of the obtained honeycomb low-temperature SCR denitration catalyst at the temperature of 160 to 250 DEG C reaches 83% and above.

Owner:HUADIAN QINGDAO ENVIRONMENTAL TECHNOLOCY CO LTD

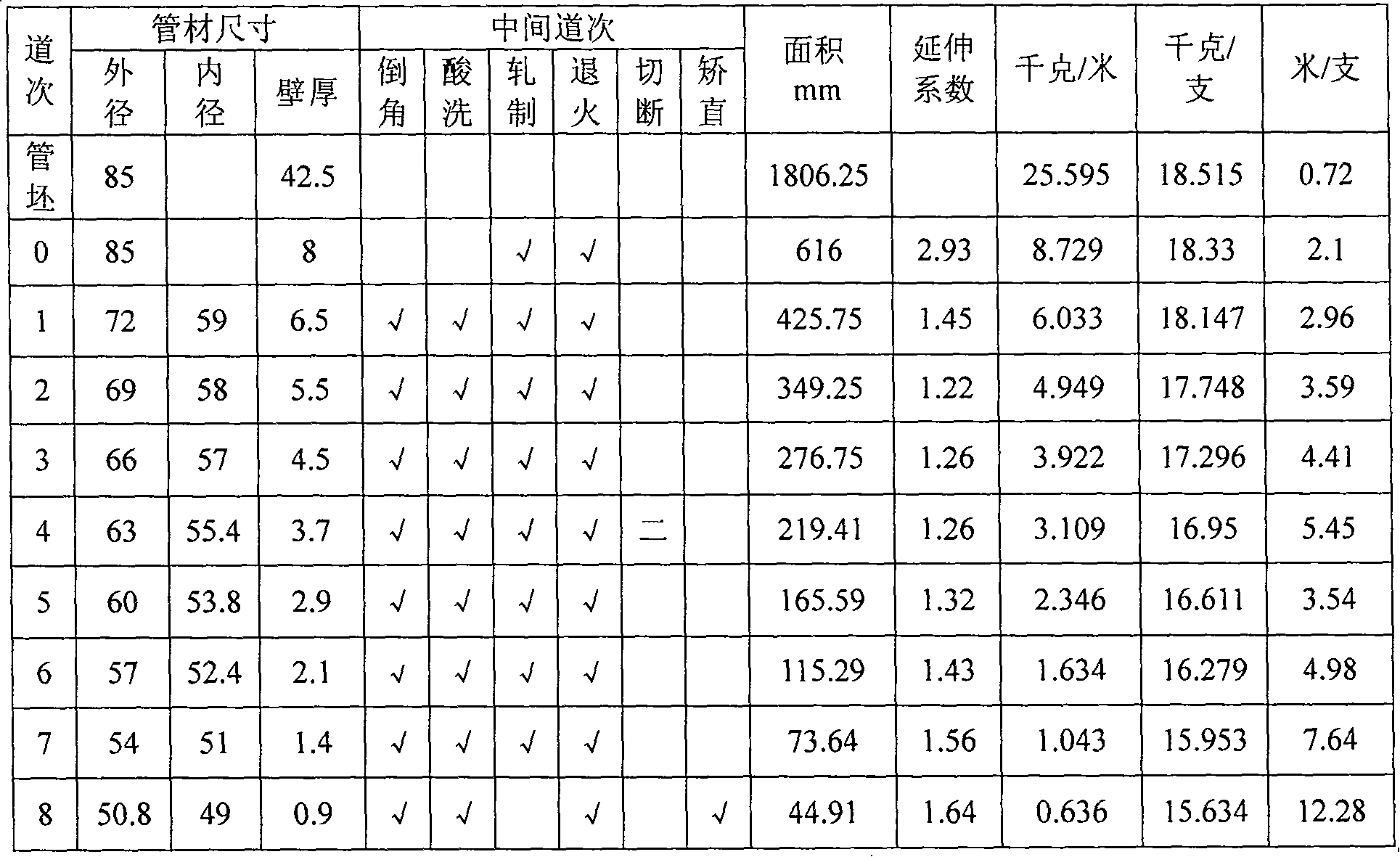

Titanium-molybdenum-nickel alloys

The invention discloses a titanium-molybdenum-nickel alloy. Compositions of the invention are that: nitrogen: less than or equal to 0.01 weight percent; carbon: less than or equal to 0.03 weight percent; hydrogen: less than or equal to 0.005 weight percent; ferrum: less than or equal to 0.08 weight percent; oxygen: less than or equal to 0.08 weight percent; molybdenum: more than or equal to 0.2 weight percent and less than or equal to 0.4 weight percent; nickel: more than or equal to 0.6 weight percent and less than or equal to 0.9 weight percent; elementary residue: less than or equal to 0.1 weight percent; gross residue: less than or equal to 0.4 weight percent; the residual composition in the alloy is titanium. The titanium-molybdenum-nickel alloy of the invention has the advantages of capability of producing an ultra-long high inside diameter-wall thickness ratio titanium alloy pipe with a length of 12 meters to 16 meters, and the titanium alloy pipe has good quality and high yield.

Owner:JIANGSU HONGBAO GROUP CO LTD

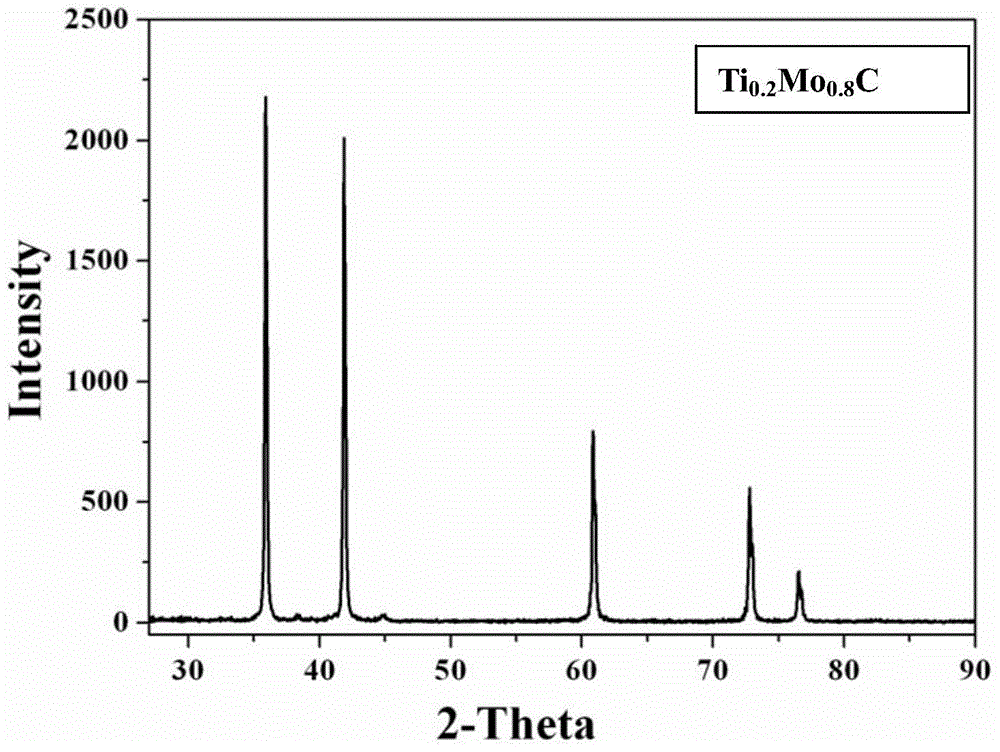

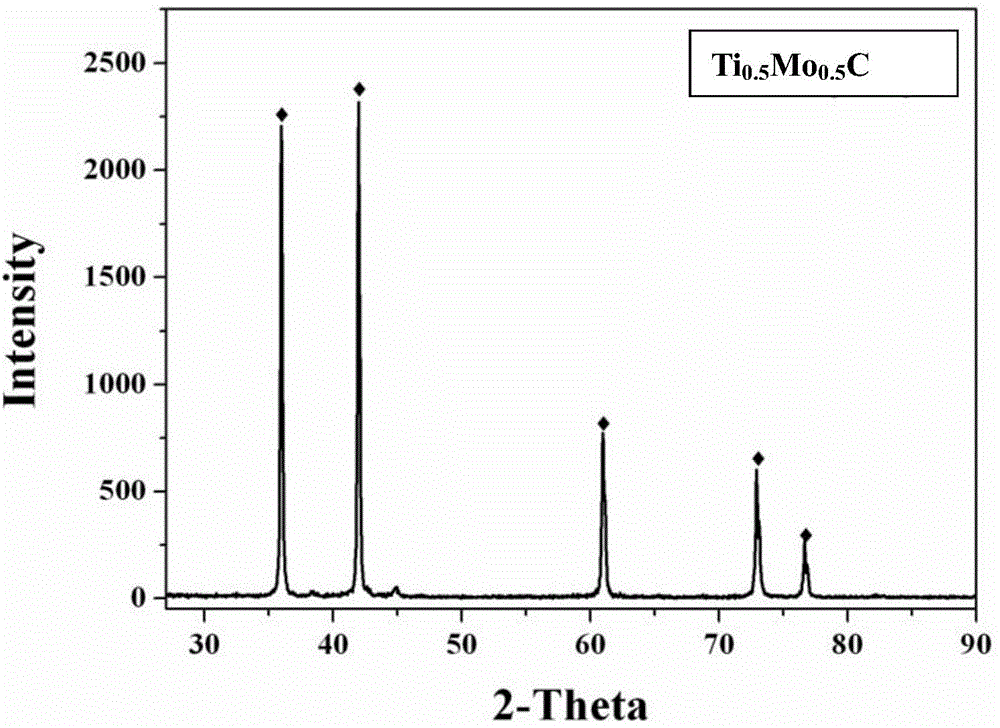

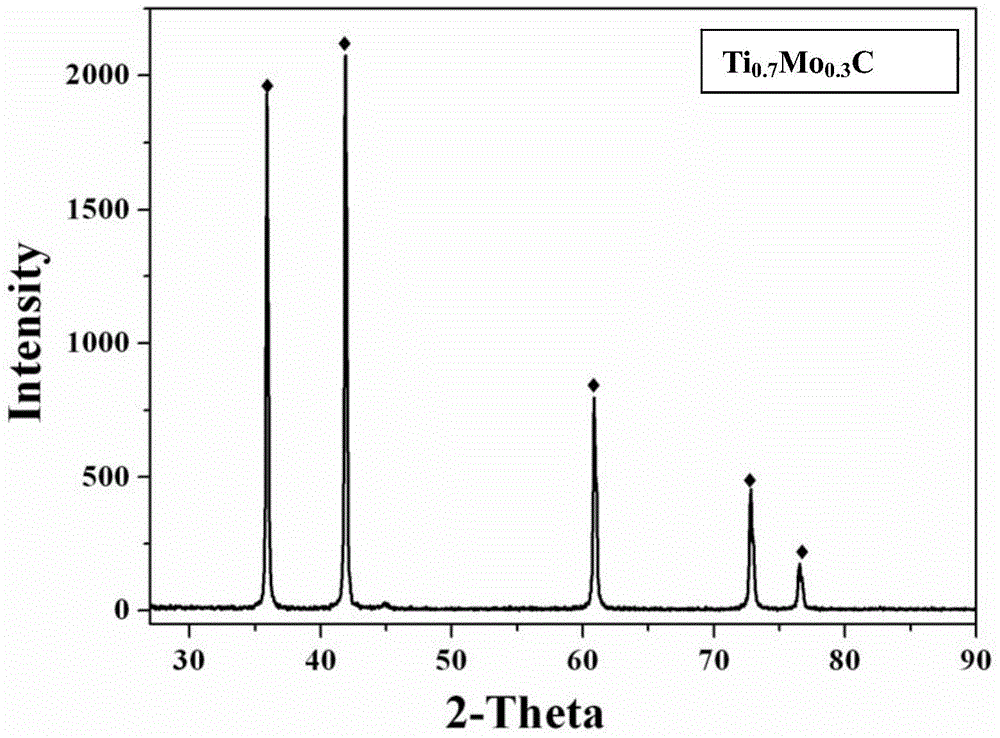

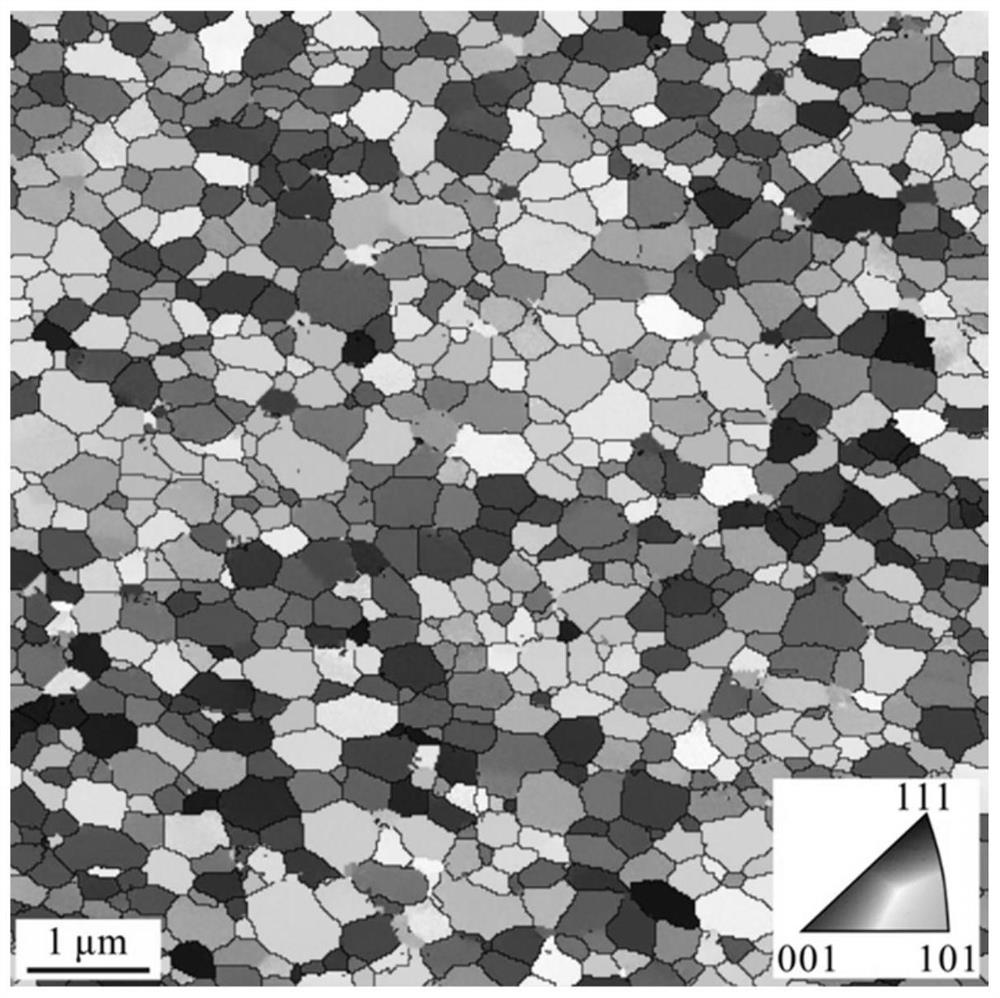

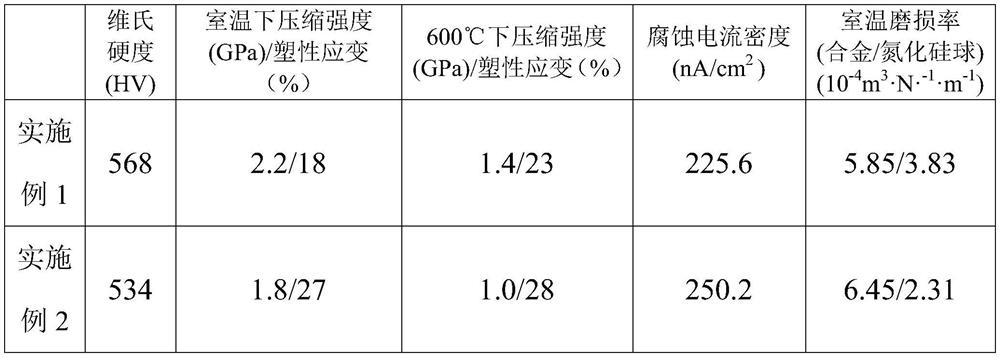

Titanium-molybdenum carbide ceramic powder and preparation method thereof

The invention relates to a titanium-molybdenum carbide ceramic powder and a preparation method thereof and belongs to the field of ceramic. The invention provides the titanium-molybdenum carbide ceramic powder with a phase structure being single cubic phase and a purity being not less than 99%. According to the invention, molybdenum powder and titanium powder are mixed uniformly according to a certain proportion and are pressed into blocks. A titanium-molybdenum alloy (TixMo1-x) is heated and smelted by electric arc generated by electrodes in a non-self-consumption vacuum melting furnace. The TixMo1-x alloy is hydrogenated for preparing TixMo1-x powders in different proportions. The TixMo1-x powders in different proportions are mixed with carbon, and then are subjected to a ball-milling process and a block-pressing process. A TixMo1-xC solid solution is prepared in a vacuum furnace in a sintering manner. The TixMo1-xC powder material is high in purity, is single in phase components, can be used not only as an additive of titanium carbide based metal ceramic or titanium carbonitride based metal ceramic but also as a substrate raw material for developing a titanium-molybdenum carbide based metal ceramic material.

Owner:临泉县非凡装饰工程有限公司

Exhaust gas purifying catalyst

ActiveUS8535628B2Improve performanceImprove oxidation activityCyanogen compoundsNitrogen compoundsPtru catalystNitrogen oxides

To overcome the problem of a conventional catalyst and to provide an exhaust gas purifying catalyst that meets the requirement concerning Hg oxidation activity and SO2 oxidation activity; i.e., an exhaust gas purifying catalyst which specifically reduces percent SO2 oxidation, while maintaining percent Hg oxidation at a high level.The invention provides an exhaust gas purifying catalyst which comprises a composition containing oxides of (i) titanium (Ti), (ii) molybdenum (Mo) and / or tungsten (W), (iii) vanadium (V), and (iv) phosphorus (P), wherein the catalyst contains Ti, Mo and / or W, and V in atomic proportions of 85 to 97.5:2 to 10: 0.5 to 10, and has an atomic ratio of P / (sum of V and Mo and / or W) of 0.5 to 1.5, and an exhaust gas purifying method comprising exposing an exhaust gas containing a nitrogen oxide (NOX) and metallic mercury (Hg) to the catalyst in the presence of ammonia as a reducing agent, to thereby perform reduction of NOX contained in the exhaust gas and oxidation of metallic mercury (Hg) contained in the exhaust gas.

Owner:MITSUBISHI POWER LTD

Intermediate alloy nickel-molybdenum 30 additive for titanium-molybdenum-nickel-titanium alloy ingot, as well as production method

The invention provides an intermediate alloy nickel-molybdenum 30 additive for a titanium-molybdenum-nickel-titanium alloy ingot, as well as a production method. The intermediate alloy additive comprises the following components in percentage by weight: 69-73% of Ni, and 29-31% of Mo, and the balance of impurities, wherein the total percentage of Ni and Mo is 100%. The production method comprises the following steps: according to the proportion of components in the alloy, preparing raw materials, pouring a mold, smelting and casting, sampling and analyzing, magnetically separating, manually sorting and encasing. According to the intermediate alloy nickel-molybdenum 30 additive and the production method, the intermediate alloy cost of the titanium-molybdenum-nickel-titanium alloy ingot can be lowered greatly; especially impurities of S, P and the like in nickel can be well removed by adding nickel-magnesium alloy in manufacturing, and magnesium is volatilized during the smelting process and has no residues in the ingot, therefore, the increase of harmful impurity elements in the titanium-molybdenum-nickel ingot can be better controlled.

Owner:武侗

Block titanium-molybdenum-niobium alloy and preparation method thereof

The invention relates to a block titanium-molybdenum-niobium alloy and a preparation method thereof. The method comprises the following steps: (1) mixing titanium powder, molybdenum powder and niobiumpowder, and grinding to obtain alloy powder; (2) sintering the alloy powder obtained in the step (1) to obtain the block titanium-molybdenum-niobium alloy; and (3) carrying out heat treatment on theblock titanium-molybdenum-niobium alloy obtained in the step (2) to obtain the block titanium-molybdenum-niobium alloy. According to the preparation method provided by the invention, the preparation process is reasonably arranged, the prepared block titanium-molybdenum-niobium alloy has the advantages of corrosion resistance, high hardness and good high-temperature resistance by utilizing the coupling effect between the steps, and the prepared block titanium-molybdenum-niobium alloy has good plasticity while maintaining high strength by adjusting and controlling the microstructure of the alloy.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

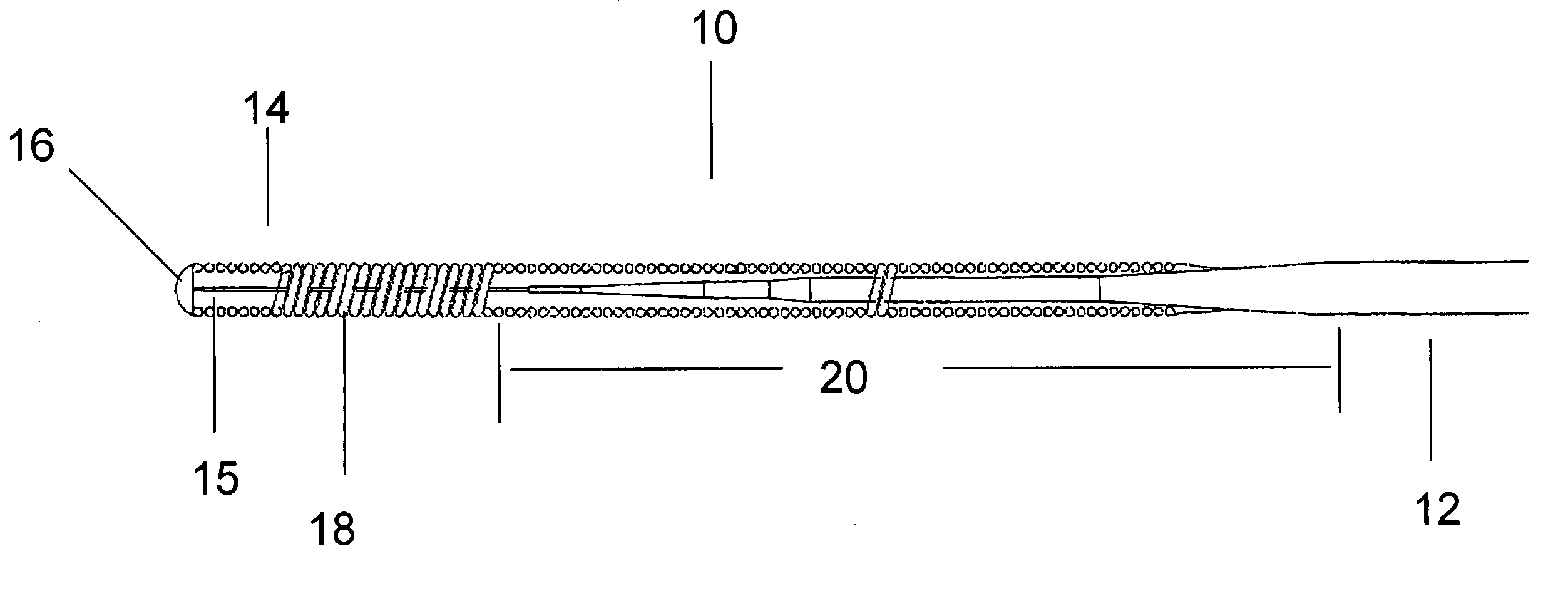

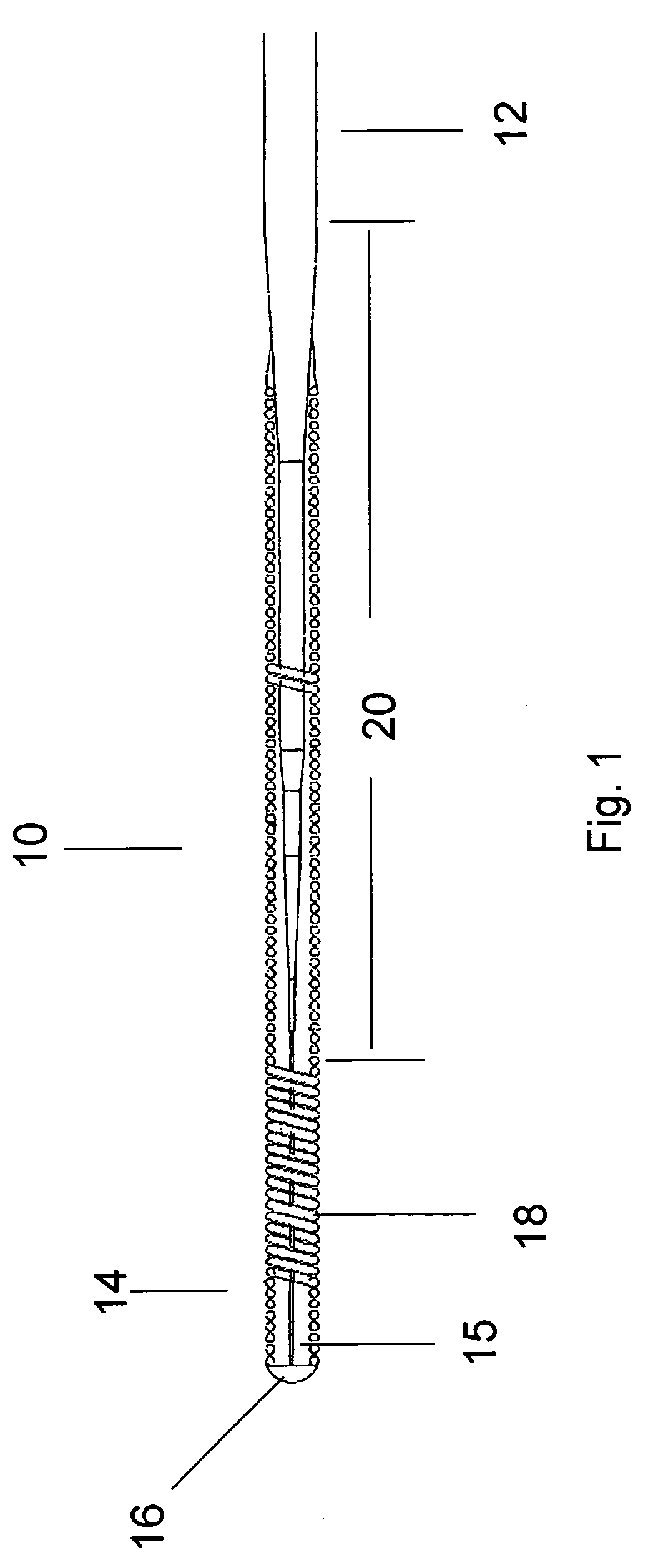

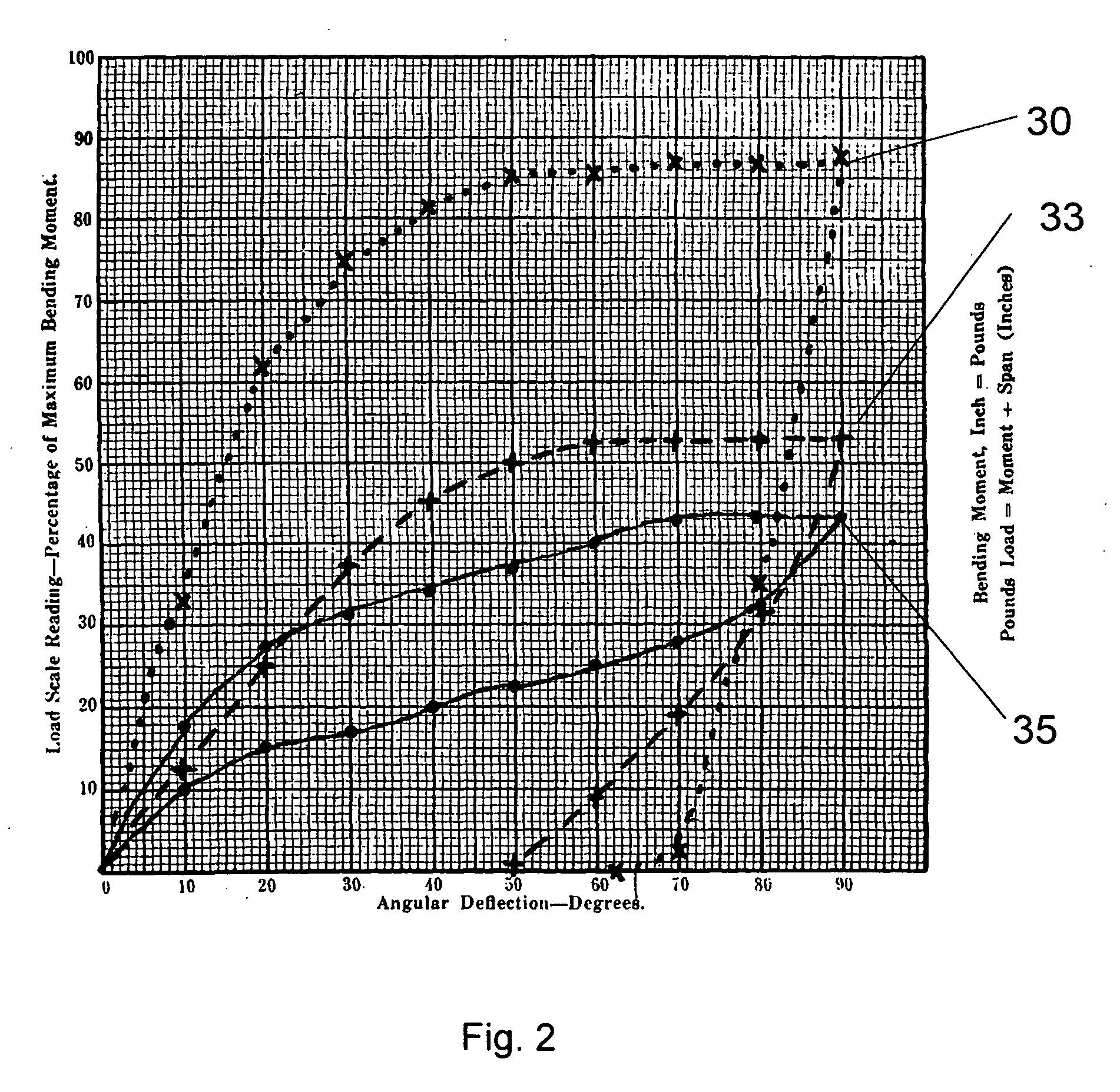

Titanium molybdenum alloy guidewire

InactiveUS20060089568A1High springbackHigh flexabilityGuide wiresDiagnostic recording/measuringNiti alloyTitanium

A guidewire for medical use such as in vascular and nonvascular systems. The guidewire made from a titanium molybdenum alloy wire with a composition of approximately 78% titanium 11.5% molybdenum 6% zinc and 4.5% tin by weight such that it is softer than stainless steel guidewires and stiffer than NiTi alloy guidewires. The distal end of the guidewire is of a smaller diameter and softer than the proximal end and fitted with a coil for springiness such that the distal end will bend when encountering curves in the body passageways. The distal tip may be heat treated for a gradient of softness with the distal tip being the softest. The distal end may also be tapered to provide an additional gradient of softness. A distal tip on the distal end of the guidewire protects the wall of the passageway from being punctured as the guidewire travels through the passageway. The resulting guidewire has properties between those of stainless steel guidewires and NiTi alloy guidewires for better torsion and stiffness characteristics.

Owner:MX MEDICAL +1

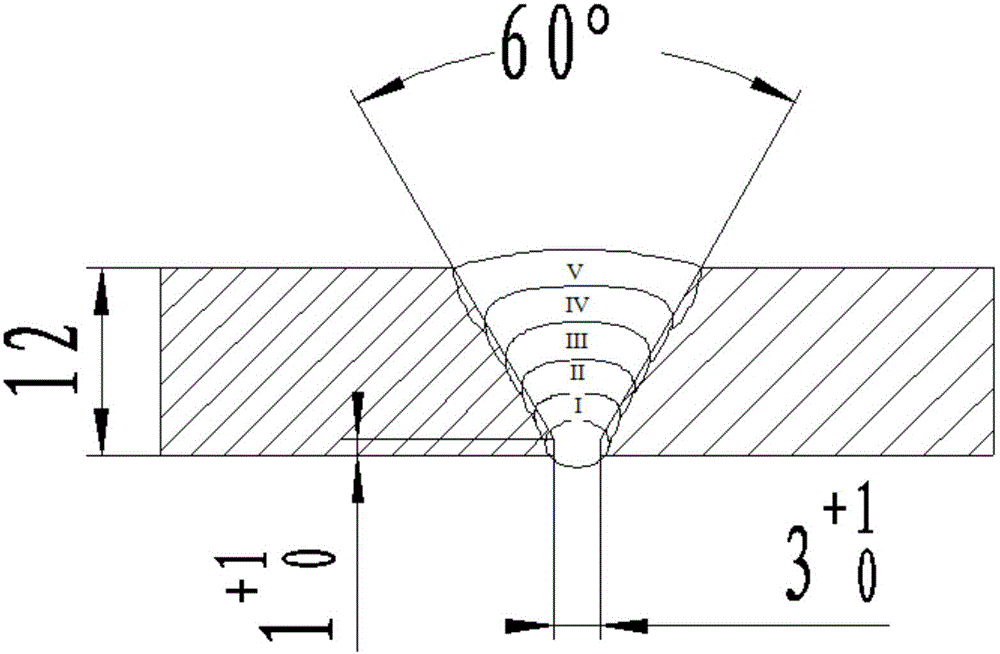

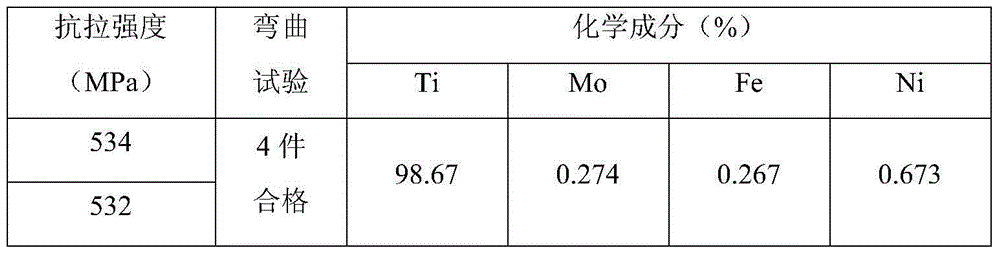

Method for automatic argon arc welding of titanium-molybdenum-nickel alloy thick filament with diameter of 2.0 mm

ActiveCN104148786AImprove welding qualitySolve bottlenecksArc welding apparatusMetal working apparatusSurface layerNickel alloy

The invention discloses a method for automatic argon arc welding of a titanium-molybdenum-nickel alloy thick filament with a diameter of 2.0 mm. The method comprises the steps of preprocessing the portion, to be welded, of a welded plate to form a V-shaped welding groove, wherein the angle of the groove is 60+ / -5 degrees, and the truncated edge is 1-2 mm long; cleaning a welding wire, the groove and inner surfaces on two sides, and removing rust, grease and dust; conducting welding on a root welding layer and cover surface layers in sequence, wherein the cover surface layers include I to V layers. By means of the automatic argon arc welding of the TA10 thick filament with the diameter of 2.0 mm, the number of welding filling times is reduced, welding quality of a TA10 device is improved, working efficiency is improved, and the labor intensity of welding operators is relieved.

Owner:LUXI IND EQUIP

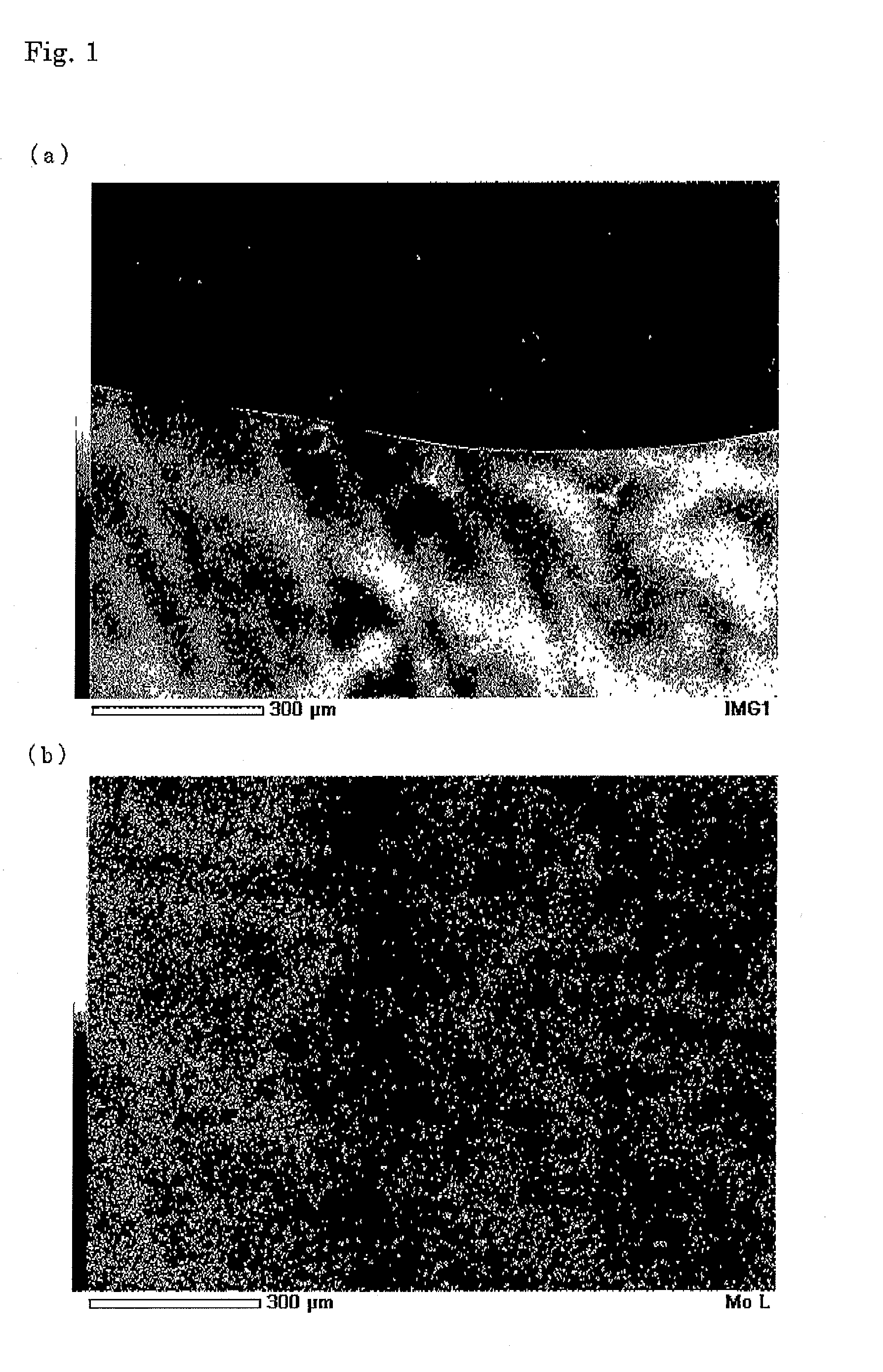

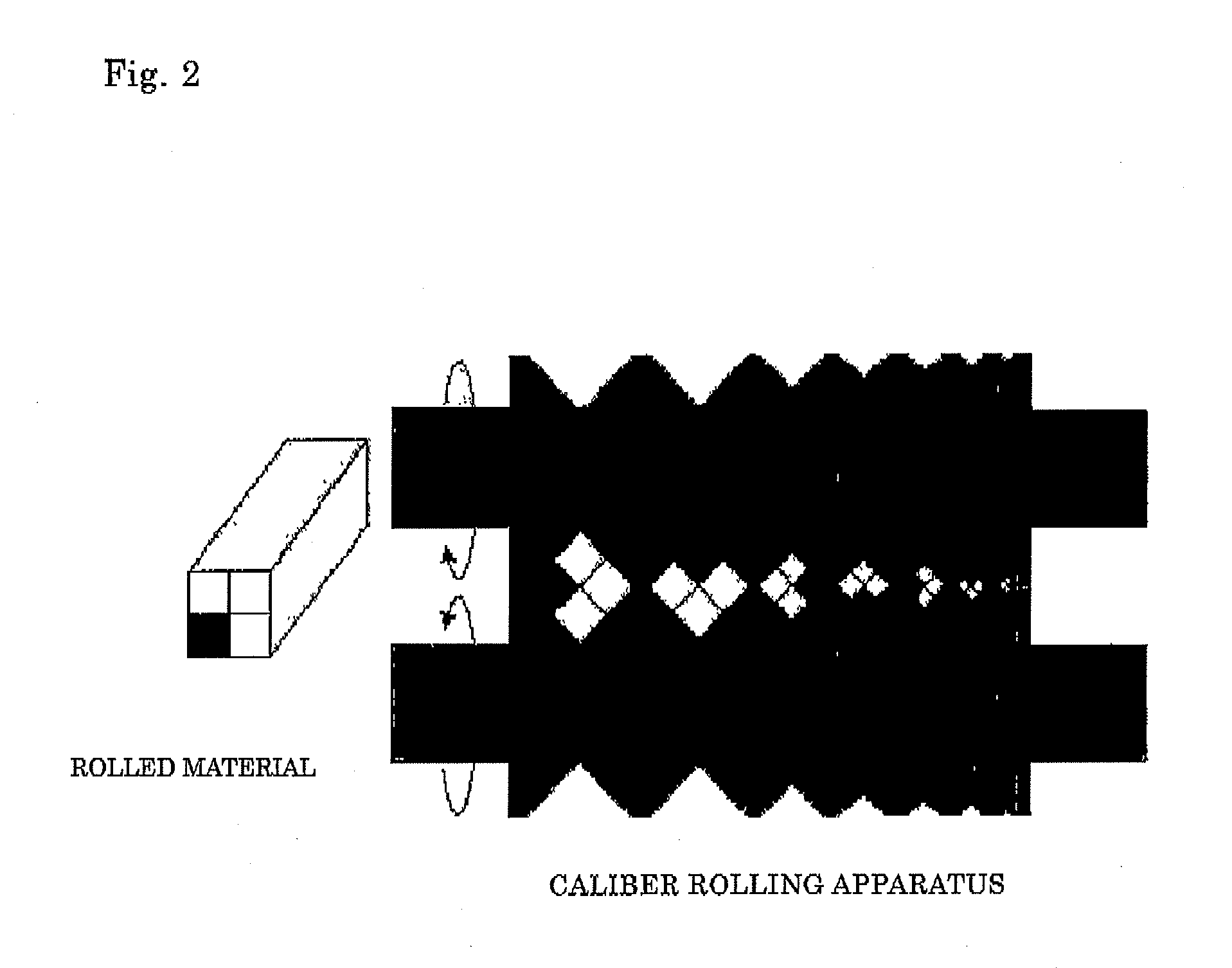

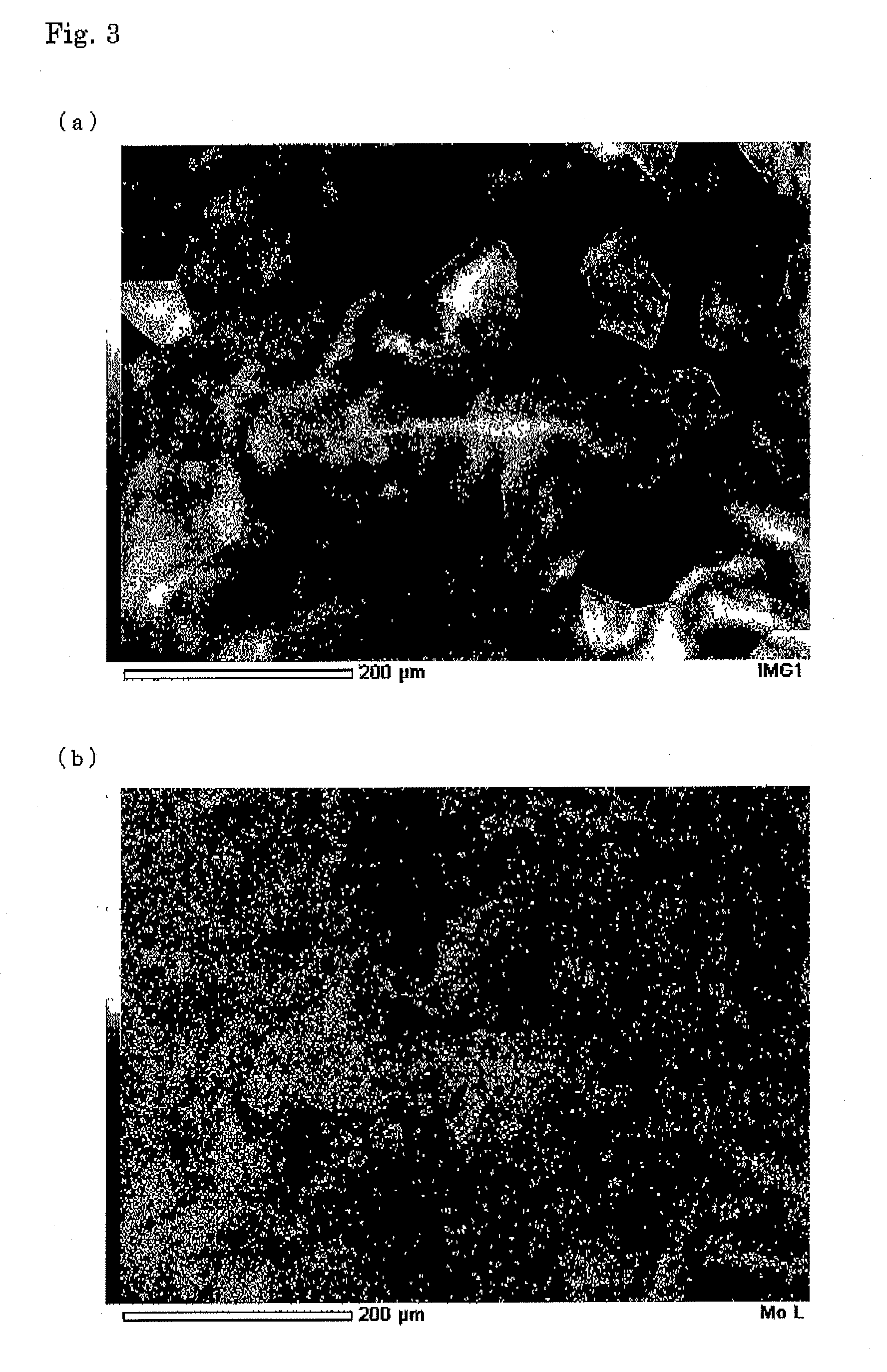

Ti-Mo ALLOY AND METHOD FOR PRODUCING THE SAME

A task of the present invention is to provide a Ti—Mo alloy material which can be improved in the yield stress at room temperature by the precipitation of an aged omega phase in the Ti—Mo alloy while maintaining large ductility at room temperature, and a method for producing the same.Provided is a Ti—Mo alloy collectively having an Mo content of 10 to 20 mass %, wherein the Ti—Mo alloy has a winding belt-like or swirly segregation portion having a width of 10 to 20 μm in the plane of a backscattered electron image (BEI) or an energy dispersive X-ray spectroscopy (EDS) image of the Ti—Mo alloy, as examined under a scanning electron microscope, in which Mo content is larger than the collective Mo content of the Ti—Mo alloy. When generally observing the entire plane examined, a segregation structure in a swirly form can be observed.Further, provided is the Ti—Mo alloy which has been subjected to aging treatment so that an aged omega phase is precipitated along the segregation portion. When generally observing the entire plane examined, an aged omega phase structure in a swirly form can be observed.

Owner:NAT INST FOR MATERIALS SCI

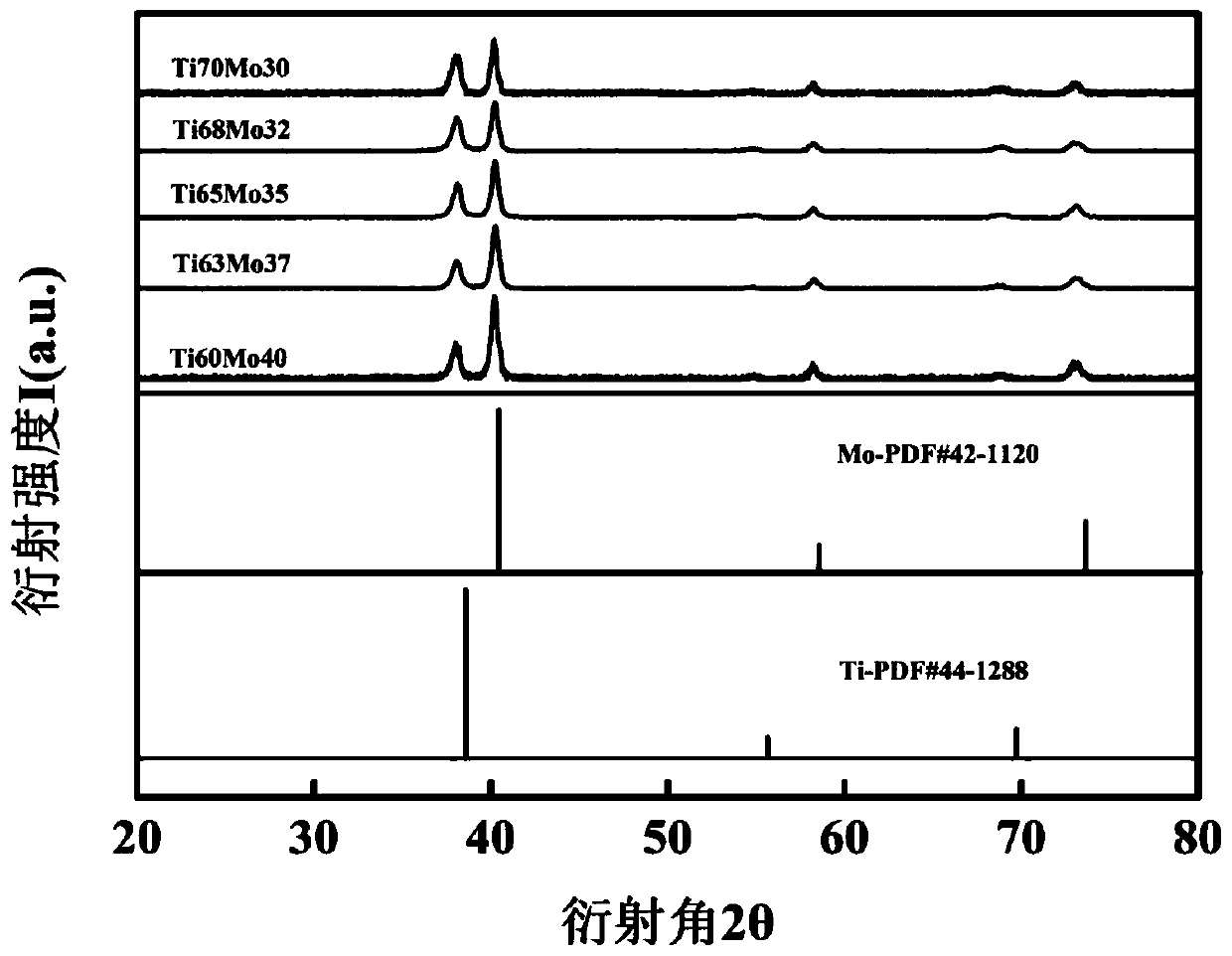

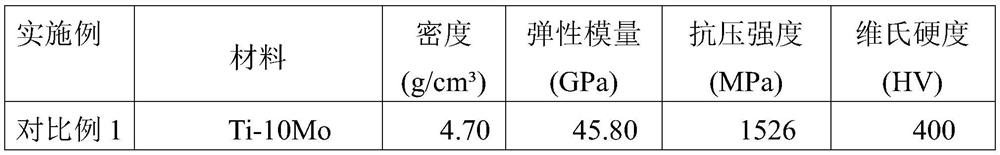

High-Mo-content biomedical beta-titanium alloy and preparation method thereof

InactiveCN106676323AMaintain structural stabilityMaintain mechanical stabilityHuman bodyMouth Rehabilitation

The invention discloses a high-Mo-content biomedical beta-titanium alloy and a preparation method thereof. The alloy comprises three alloy elements including titanium (Ti), molybdenum (Mo) and stannum (Sn). Alloy components of the alloy comprise, by weight percent, 20%-60% of the molybdenum (Mo), 0-20% of the stannum (Sn) and the balance titanium (Ti). The alloy is prepared through a high-temperature melting method, an electric arc melting method, a powder metallurgic method, a high-frequency induction method or a mechanical alloy method. The alloy has the following beneficial effects that the alloy elements including molybdenum and stannum completely compatible with the human body are selected, excellent biocompatibility is achieved, and toxicity is avoided; and the elasticity modulus is low (E=50-60 GPa) and is lower than that of a Ti-6Al-4V alloy by 40%-50%. The alloy can be used as a biomedical titanium alloy for dentistry and is mainly used for clinic mouth rehabilitation, implanting, orthodontics and the like.

Owner:GUANGXI UNIV

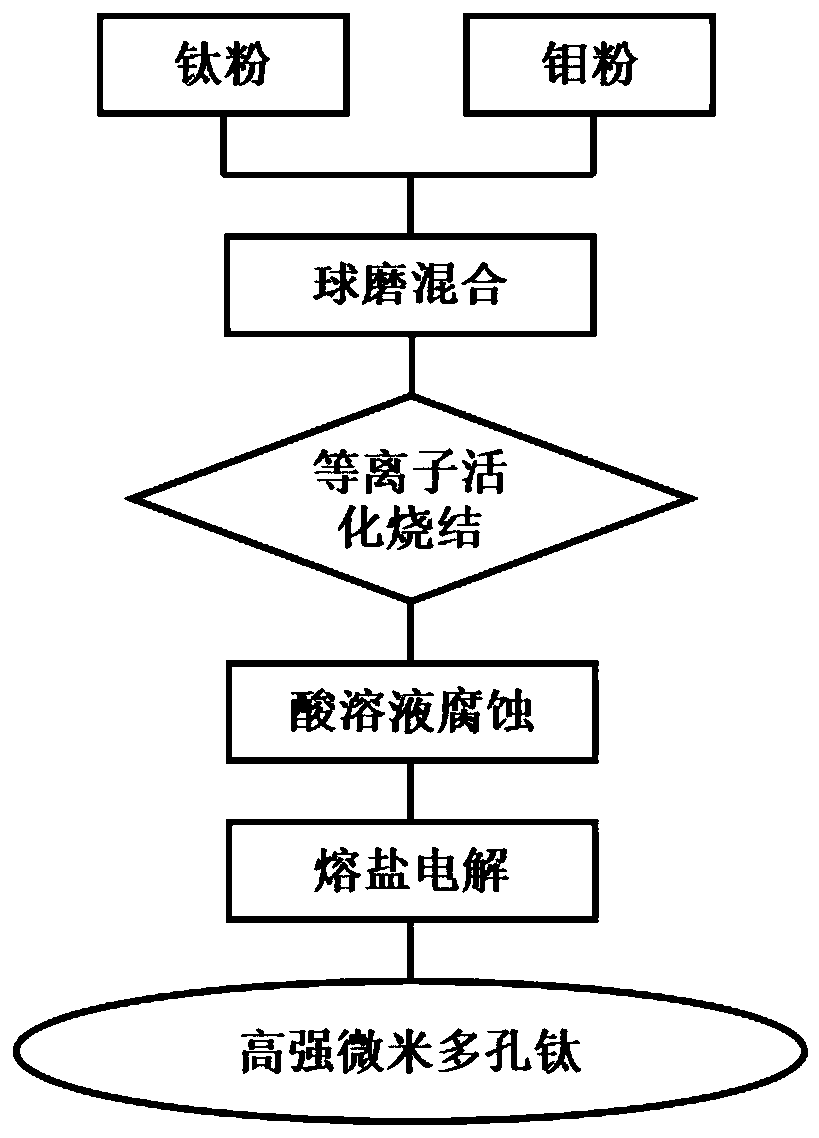

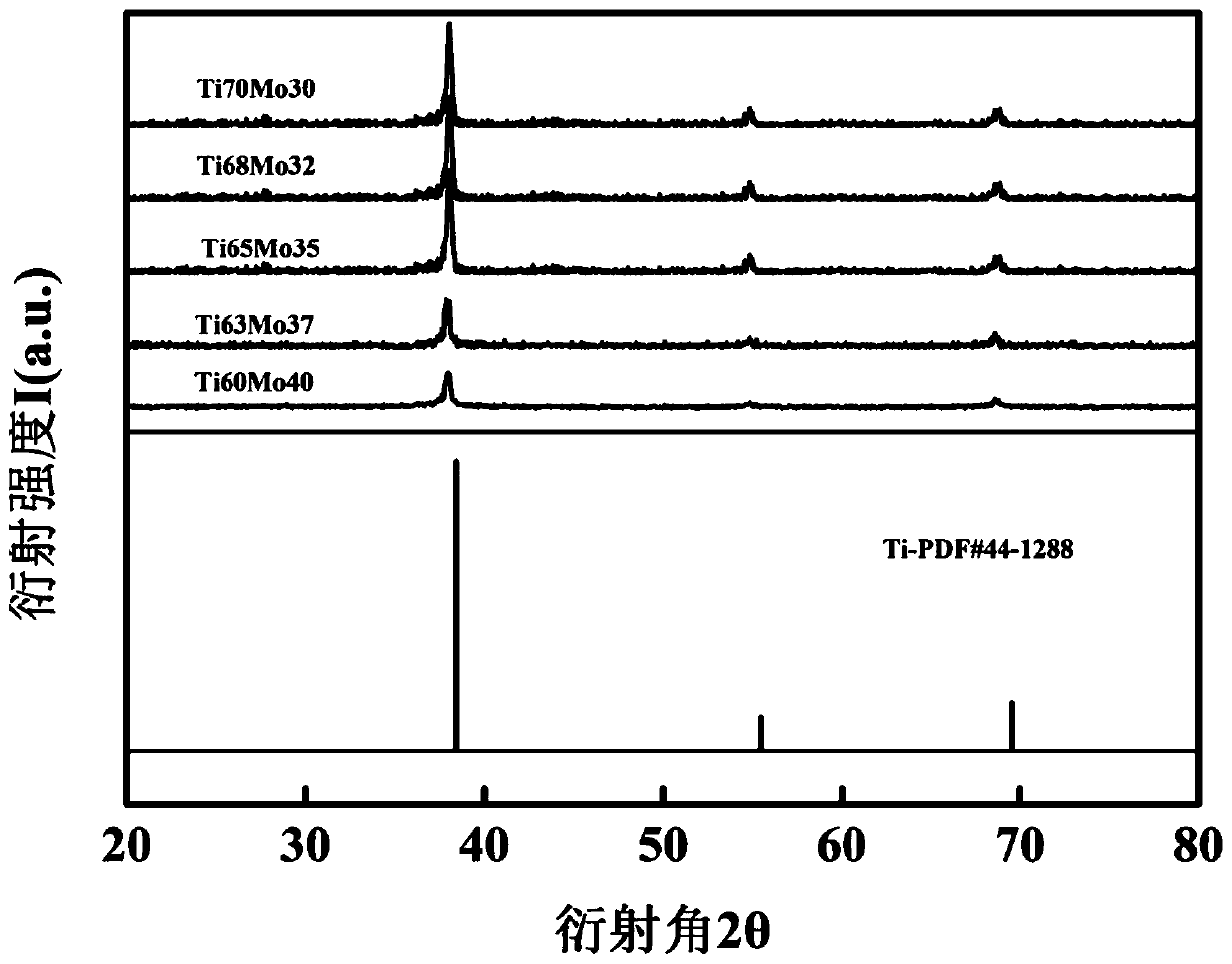

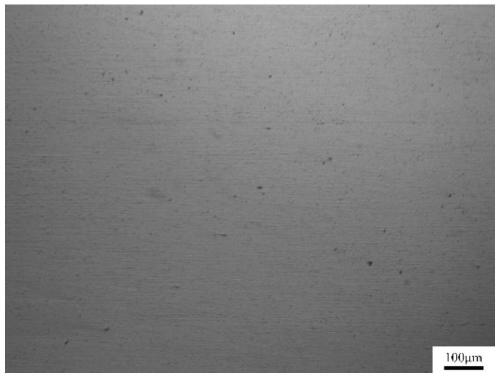

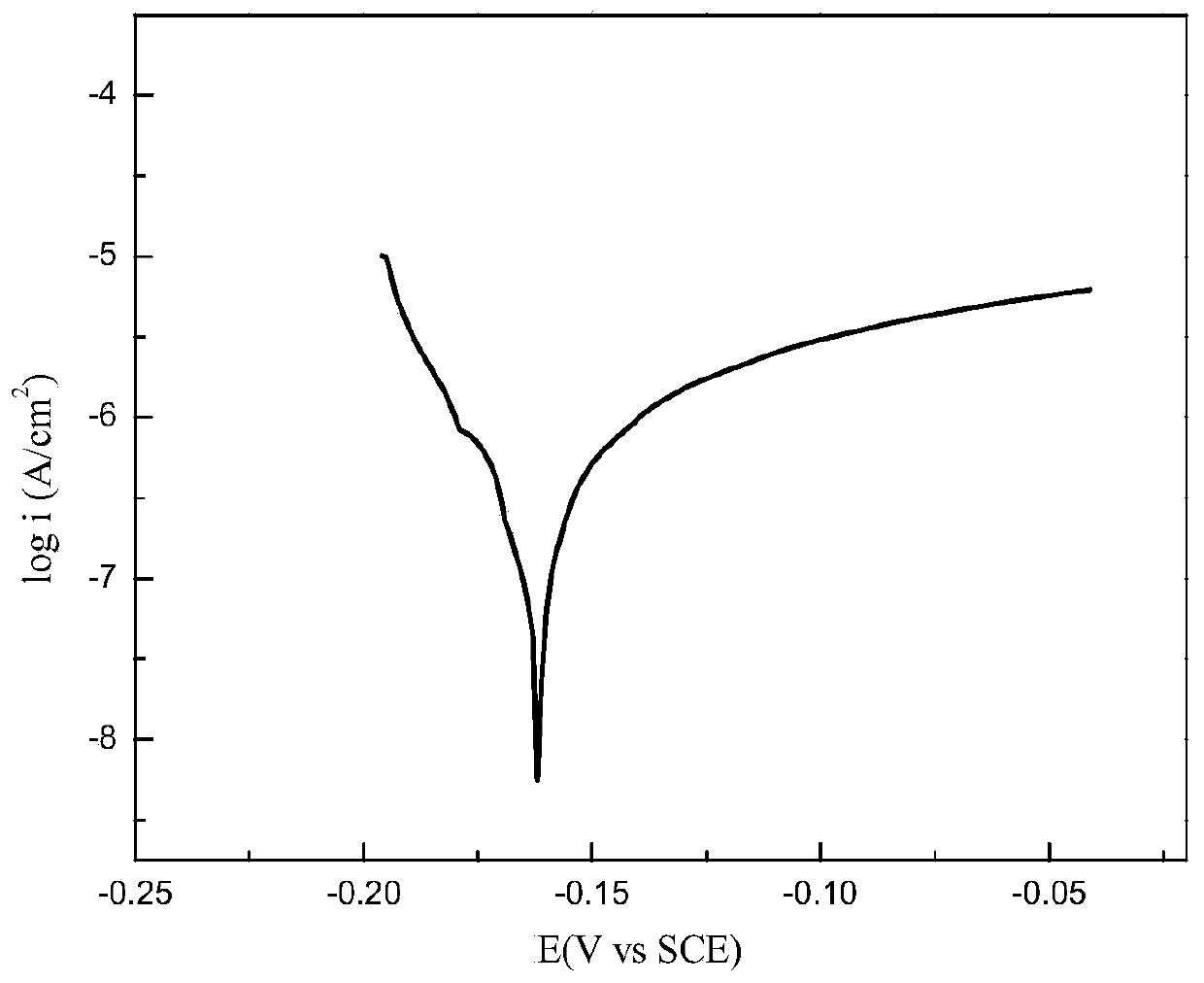

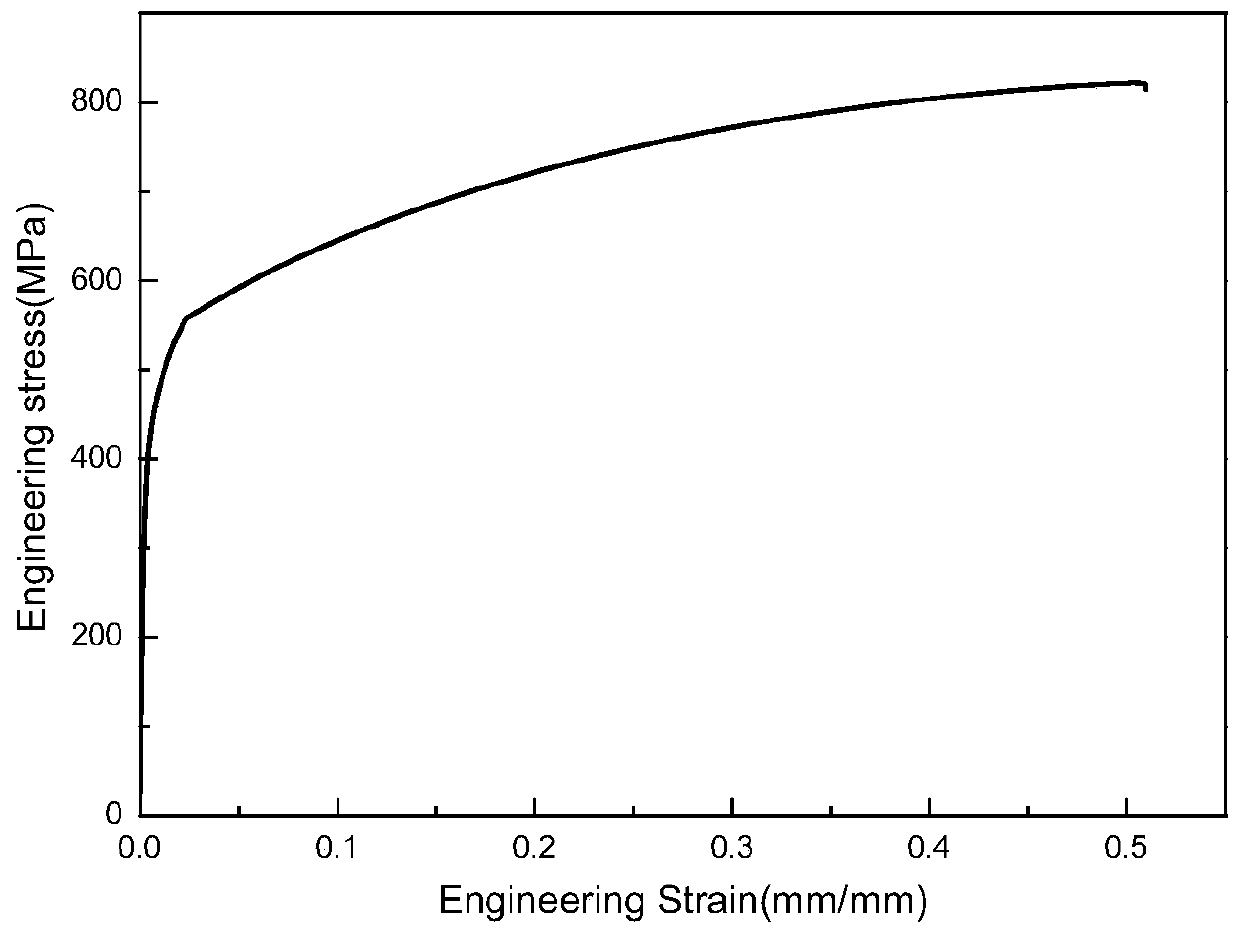

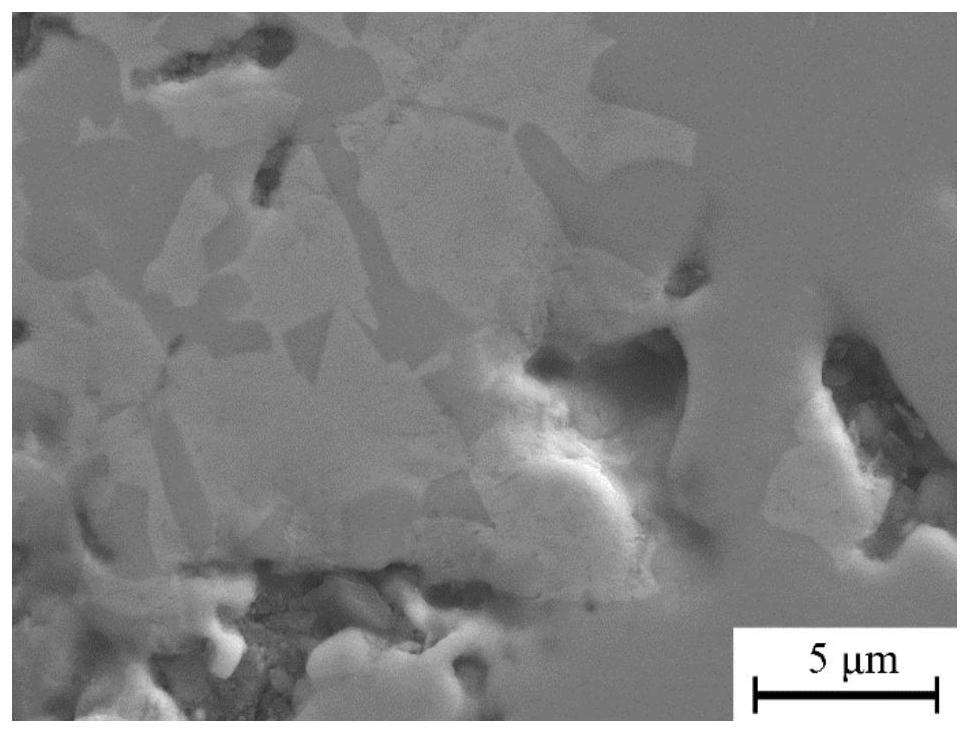

Method for preparing high-strength micro porous metallic titanium block by dealloying titanium-molybdenum alloy

The invention provides a method for preparing a high-strength micro porous metallic titanium block by dealloying a titanium-molybdenum alloy. The method is characterized in that the titanium-molybdenum alloy is treated through plasma activated sintering, molybdenum in the alloy is corroded selectively in a dealloying manner, obtained porous titanium is subjected to deoxidation and secondary sintering by the combination with a molten salt electrolysis method, so that the purity and the mechanical performance of a porous titanium block are greatly improved, and the high-strength porous titaniumblock is obtained. A titanium-molybdenum bicontinuous three-dimensional network-structured titanium-molybdenum alloy is prepared through plasma activated sintering; the pore structure of the porous metallic titanium block is regulated and controlled by changing the content of titanium and molybdenum elements; the obtained porous titanium is subjected to deoxidation and secondary sintering by adopting the molten salt electrolysis method, so that the purity and the mechanical performance of the porous titanium block are greatly improved; the high-strength porous titanium block of which the aperture is 5-10 [mu]m, the porosity is 78.5%-44.6%, and the compressive strength can reach 152.3 MPa can be obtained by adopting the process; and the method has the advantages of simple process, low cost,high practicability and the like.

Owner:WUHAN UNIV OF TECH

Silver powder-containing metallurgic titanium-molybdenum-aluminum-vanadium alloy and preparation method thereof

The invention provides a silver powder-containing metallurgic titanium-molybdenum-aluminum-vanadium alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 2 to 8 percent of Mo, 3 to 7 percent of Al, 2 to 6 percent of V, 2 to 10 percent of Ag and the balance of titanium and inevitable impurities. The preparation method comprises the following steps of: according to the weight percentages of the components, weighing titanium powder, molybdenum powder, aluminum powder, silver powder and aluminum vanadium intermediate alloy powder with certain granularity; uniformly mixing the powder by adopting a mixing method; and pressing the powder to prepare a green body with certain shape through a compression molding process; putting the green body in a vacuum sintering furnace for sintering, and obtaining the argentiferous titanium-molybdenum-aluminum-vanadium alloy after the furnace is cooled. In the preparation method, the process flow is simple, the silver powder is added into mixture to improve the compactibility of the green body and further increase the density of a sintered body, and thus, the highly-densified silver powder-containing metallurgic titanium alloy is obtained. The preparation method is suitable for industrialized production.

Owner:CENT SOUTH UNIV

Hafnium-zirconium-titanium-molybdenum strengthened austenitic stainless steel and preparation method thereof

The invention discloses hafnium-zirconium-titanium-molybdenum strengthened austenitic stainless steel and a preparation method thereof. The austenitic stainless steel is prepared from, by mass, smaller than or equal to 0.05% of C, 10.0%-14.0% of Ni, 15.0%-19.0% of Cr, smaller than or equal to 0.1% of Ti, 2.0%-3.0% of Mo, smaller than or equal to 1% of Hf, smaller than or equal to 0.24% of Zr, smaller than or equal to 2.0% of Mn, smaller than or equal to 1.0% of Si, smaller than or equal to 0.035% of P, smaller than or equal to 0.030% of S and the balance Fe, wherein the content of Hf is largerthan or equal to 14.86*C / 2 and smaller than or equal to 1, and the content of Zr is larger than or equal to 0.1 and smaller than or equal to 7.6*C / 2+0.05. The preparation method comprises the following steps of (1) smelting and casting of the stainless steel, (2) hot-rolling cogging, (3) cold-rolling deformation and (4) high-temperature heat treatment. According to the hafnium-zirconium-titanium-molybdenum strengthened austenitic stainless steel and the preparation method thereof, zirconium, hafnium, titanium and molybdenum are added into the stainless steel, not only can the strength be improved, but also the irradiation resistance of the austenitic stainless steel can be improved; and in a H2SO4 electrolyte of 0.5 mol / L at 80 DEG C, the corrosion rate of the austenitic stainless steel ranges from 10.2 microamps / cm<2> to 16.2 microamps / cm<2>, the plasticity of the austenitic stainless steel is higher than 43%, and the tensile strength is higher than 822 MPa.

Owner:NANJING YOUTIAN METAL TECH

High strength steel sheet having excellent formability and a method of manufacturing the steel sheet

ActiveUS11466335B2Increase weightSimple structureHot-dipping/immersion processesFurnace typesManganeseImpurity

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

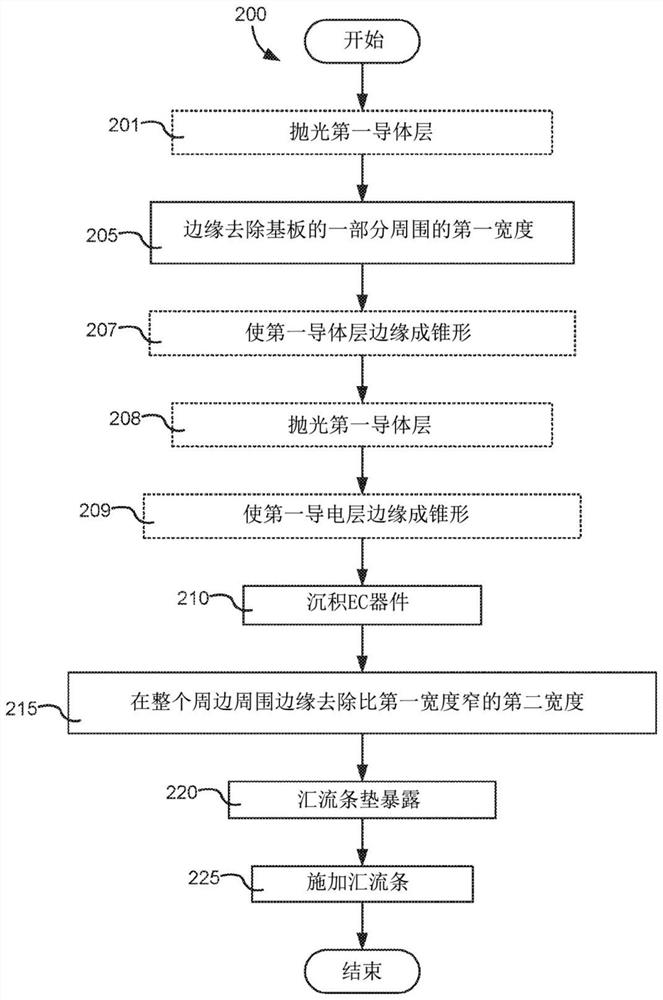

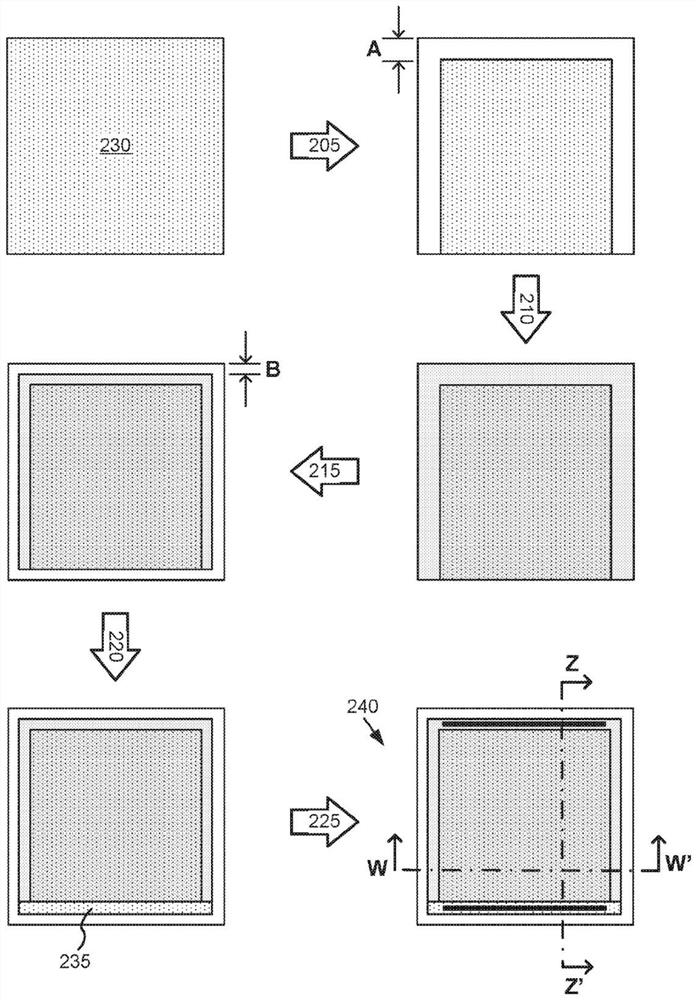

Electrochromic devices comprising tungsten titanium molybdenum oxide as electrochromic material

Various embodiments herein relate to electrochromic devices, as well as methods and apparatus for fabricating such electrochromic devices, wherein the material of the electrochromic layer (106) includes tungsten titanium molybdenum oxide which is cathodically coloring. In certain embodiments, the electrochromic device may include one or more particular counter electrode materials. The material ofthe counter electrode material may include electrochromic nickel tungsten oxide, nickel tungsten tantalum oxide, nickel tungsten niobium oxide, nickel tungsten tin oxide, or another nickel-based anodically coloring material.

Owner:VIEW INC

Preparation method of molybdenum-titanium alloy material

The invention discloses a preparation method of a molybdenum-titanium alloy material. The method is carried out in a high-temperature evaporation chamber, a cooling tube and a collector which communicate with one another in sequence. The preparation method comprises the following steps that a molybdenum raw material and a titanium raw material which are added are evaporated into mixed vapor through the high-temperature evaporation chamber, then the mixed vapor is cooled into fine particles in a water cooling manner through the cooling tube, then, then the fine particles enter the collector through a filter screen with fine filter holes, and finally drying is carried out to obtain high-purity nanoscale titanium-molybdenum alloy powder. By using the mode, the oxygen content in the prepared titanium-molybdenum alloy powder can be reduced, the titanium-molybdenum purity is greatly improved, and the particle size of the alloy powder is consistent.

Owner:王鹏

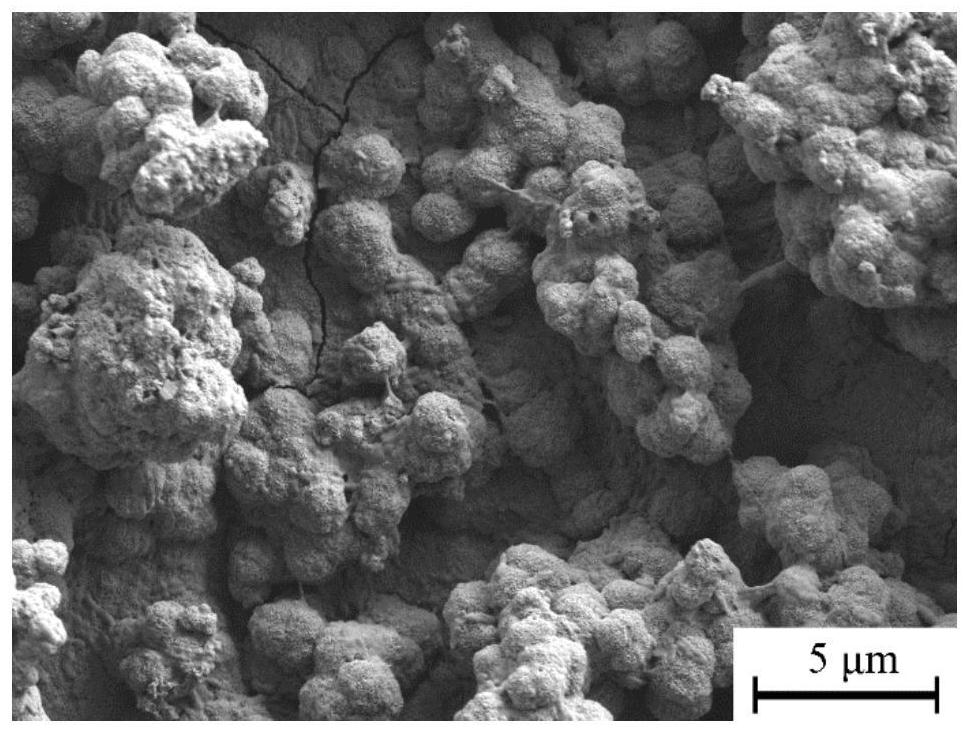

Bone repair titanium-molybdenum-based hydroxyapatite composite material and preparation method thereof

ActiveCN113046596AHigh compressive strengthHigh strengthProsthesisOsseointegrationCompressive strength

The invention discloses a bone repair titanium-molybdenum-based hydroxyapatite composite material and a preparation method thereof. The composite material is prepared by mixing a titanium-molybdenum alloy, a process control agent and hydroxyapatite. The prepared composite material is low in elasticity modulus (30-50 GPa), high in compressive strength (500-1550 MPa) and high in hardness (300-520 HV), contains a large number of bioactive ceramic phases (CaTiO3, Ca3 (PO4) 2, HA and the like), is beneficial to induction of osseointegration, has excellent mechanical properties and biological activity, and can be used for bone repair and bone replacement.

Owner:JIANGNAN UNIV

Catalyzing composition for purifying air

InactiveCN105435814AHigh activityPlay a catalytic roleGas treatmentHeterogenous catalyst chemical elementsCeriumPotassium

The invention discloses a catalyzing composition for purifying air. The catalyzing composition comprises the following raw components: (A) 6%-20% of a nanometer TiO2 loaded platinum cerium silver potassium composite oxide, (B) 3%-8% of zirconium doped iron titanium molybdenum vanadium composite oxide, and (C) the balance being activated carbon, wherein in A, the molar ratio of Ti to Pt to Ce to Ag to K is 1 to (0.05-0.1) to (0.05-0.1) to (0.05-0.1) to (0.05-0.1); in B, the molar ratio of Zr to Fe to Ti to Mo to V is (0.02-0.2) to 1 to (0.5-1) to (0.5-1) to (0.5-1); iron titanium molybdenum composite oxide has a composite oxide minicrystal system which is of Fe-O-Ti, Mo-O-Ti and Fe-O-Mo structures. The catalyzing composition can be loaded / doped on a fiberglass filtering element or a filtering mesh, and can be used for catalyzing and purifying organic pollutants and hazes in the air so as to enable the pollutants to be reduced to the ppm level.

Owner:WUXI QINGYANG MACHINERY MFG

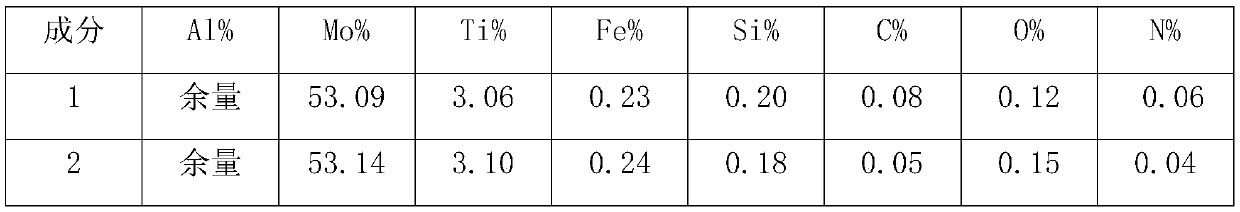

Aluminum-titanium-molybdenum intermediate alloy and preparation method thereof

The invention discloses an aluminum-titanium-molybdenum intermediate alloy. The alloy comprises, by mass, 50.0-55.0% of molybdenum, 1.0-5.0% of titanium and the balance being aluminum. The preparationmethod of the aluminum-titanium-molybdenum intermediate alloy comprises the following steps of uniformly mixing aluminum, molybdenum trioxide and calcium fluoride, placing a mixture into a reaction crucible for aluminothermic reaction to obtain an alloy liquid, and cooling the alloy liquid to obtain an aluminum-molybdenum intermediate alloy; and uniformly mixing the aluminum-molybdenum intermediate alloy and titanium sponge, placing a mixture into a smelting crucible, performing vacuumizing, argon filling and smelting, performing refining after materials are completely melted to obtain an alloy liquid, and performing casting and cooling to obtain the aluminum-titanium-molybdenum intermediate alloy. According to the aluminum-titanium-molybdenum intermediate alloy and the preparation methodthereof, the aluminum-titanium-molybdenum intermediate alloy is uniform in component, small in segregation and low in impurity content.

Owner:CHENGDE TIANDA VANADIUM IND

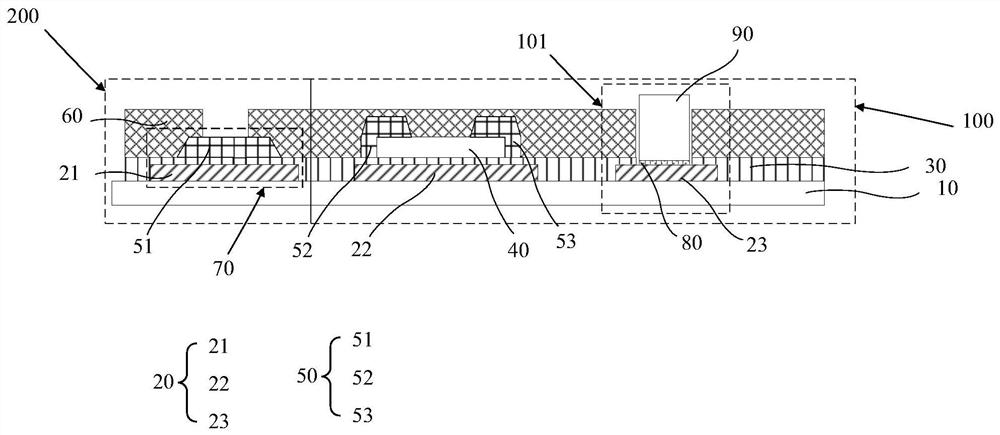

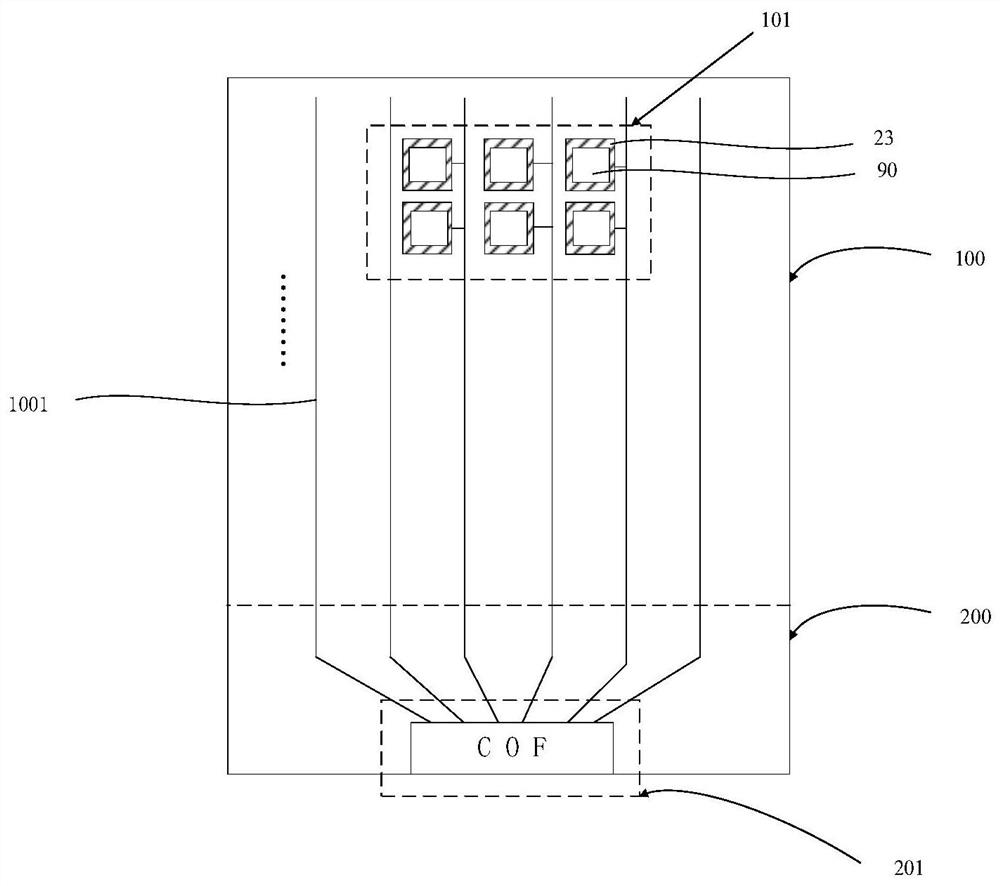

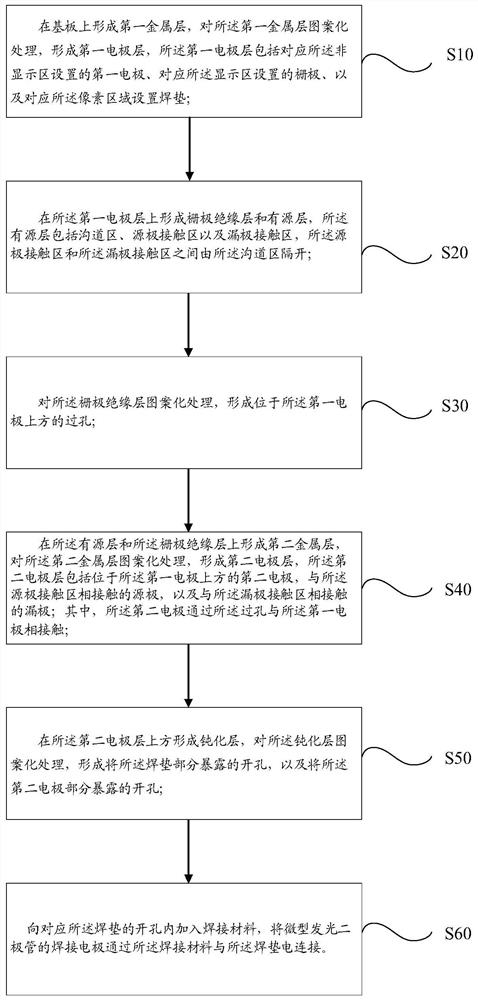

Display panel, preparation method thereof and display device

ActiveCN111682044AImprove bindingReduce processSolid-state devicesSemiconductor devicesManufacturing cost reductionDisplay device

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

High-strength composite solder

InactiveCN110076476AMaterial deviation is smallImprove matchWelding/cutting media/materialsSoldering mediaSlagManganese

The invention relates to high-strength composite solder. Deposited metal formed by the solder comprises, by mass percentage, 0.04%-0.08% of carbon, 0.30%-0.50% of silicon, 4%-8% of manganese, 10%-18%of nickel, 4%-8% of chromium, 2%-4% of titanium, 0.4%-0.8% of molybdenum, 60%-70% of iron and the balance impurities, specifically, the weight ratio of the nickel to the chromium is 2-3:1. The high-strength composite solder has the high strength and the high mechanical stretch performance, is stable in performance under the high temperature condition, low in cost and few in electric arc splash, and easily achieves slag removal.

Owner:HUANGSHI GAOCHAO IND & MINING MACHINERY

Titanium alloy valve rod preparation method of plug valve

The invention discloses a titanium alloy valve rod preparation method of a plug valve. The process comprises a first step of choosing beta titanium alloy with titanium and the molybdenum as a cast object, wherein the content of molybdenum is from 6.5% to 18%. The beta alloy is fused under the temperature higher than 1550 DEG C, and the fused alloy is cast precisely into a valve rod blank piece. Hot isostatic pressure can be carried out when the highest temperature is equal to beta transformation temperature of the titanium and molybdenum alloy and the lowest temperature is 100 DEG C lower than beta transformation temperature. Solution annealing is carried out under the temperature from 700 DEG C to 900 DEG C. The alloy is heated to 650-760 DEG C. The process of heat preservation is carried out for 3-5 hours. When a furnace is cooled to 300 DEG C, the process of the heat preservation is carried out for 4 hours, and then the alloy is heated to 650-760 DEG C. The process of the heat preservation is carried out for 17 hours. The alloy is cooled to 450 DEG C at a speed of 50 DEG C per hour and then at a speed of 20 DEG C per hour, and the beta alloy is cooled to 140 DEG C. Heat treatment and subzero treatment have high production continuity. Material utilization rate is high. The beta alloy is suitable for mass production, and cost is reduced.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

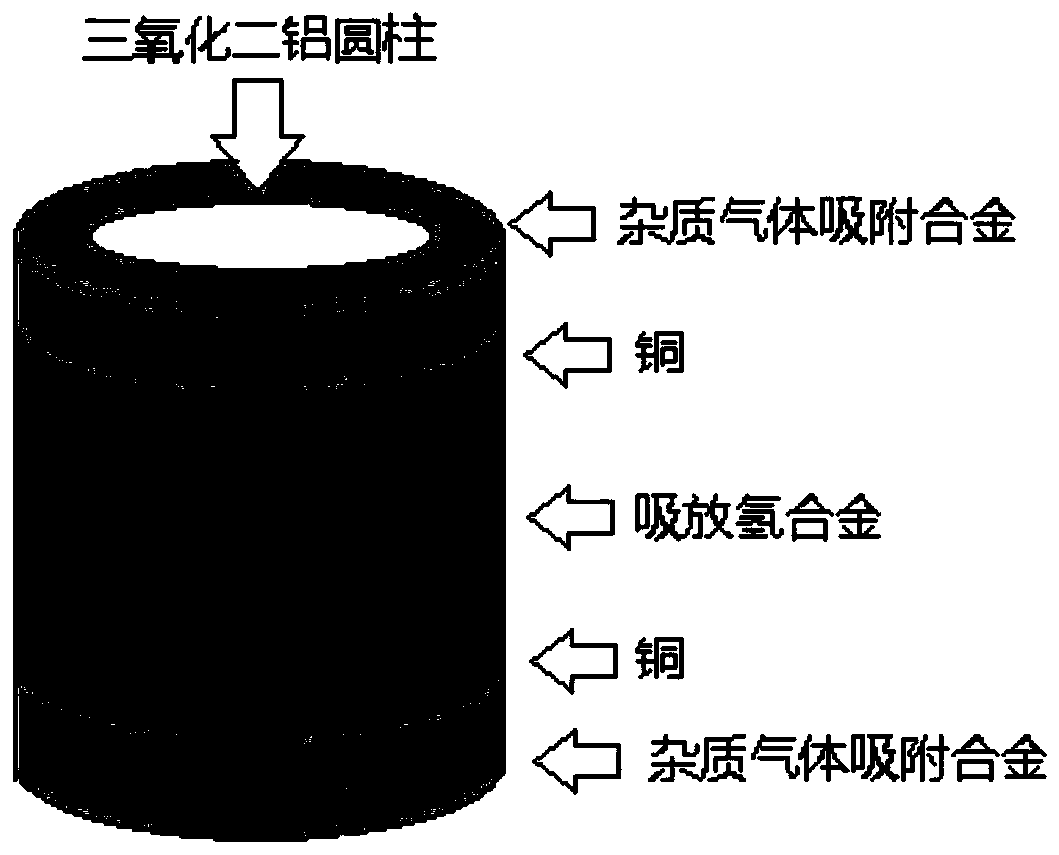

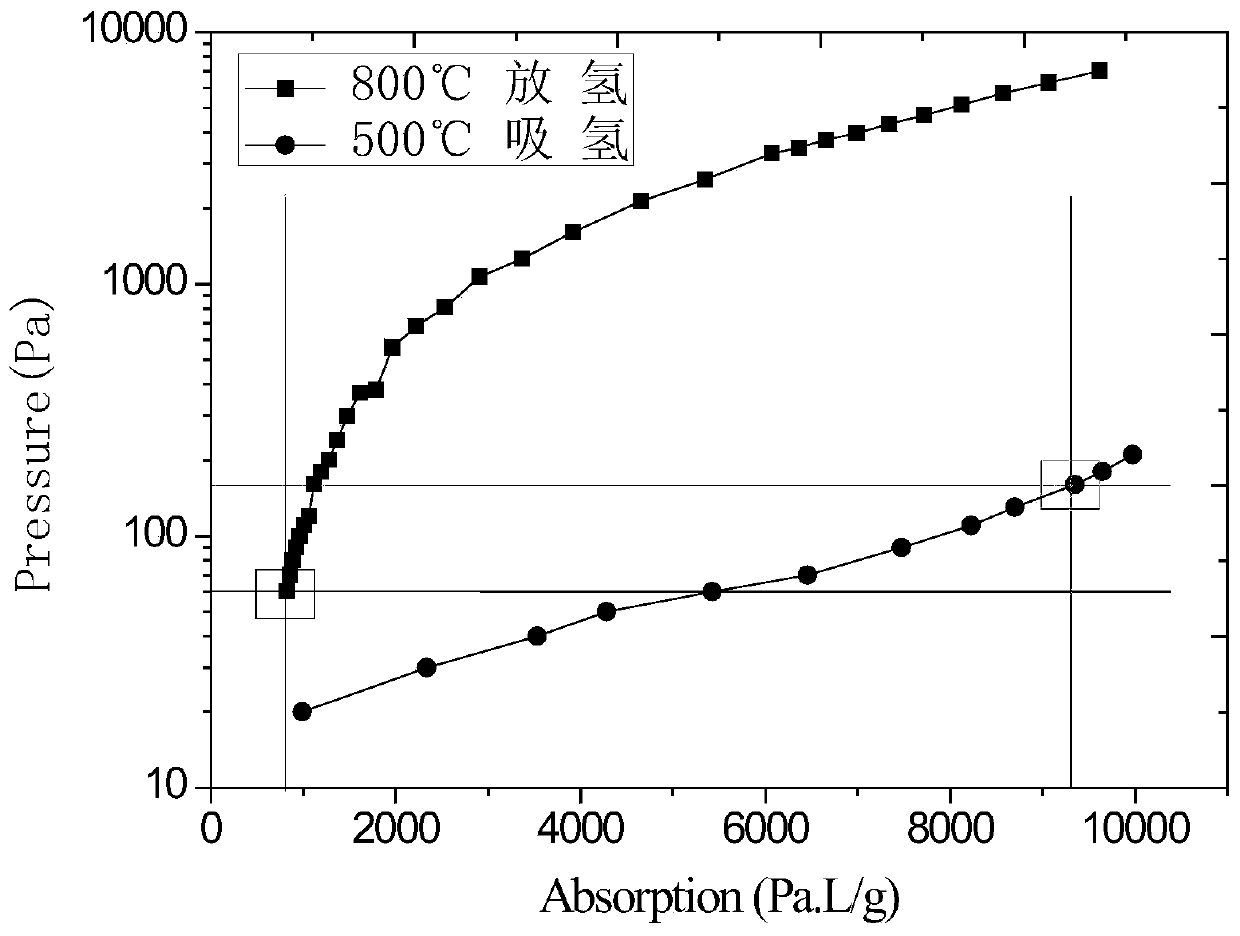

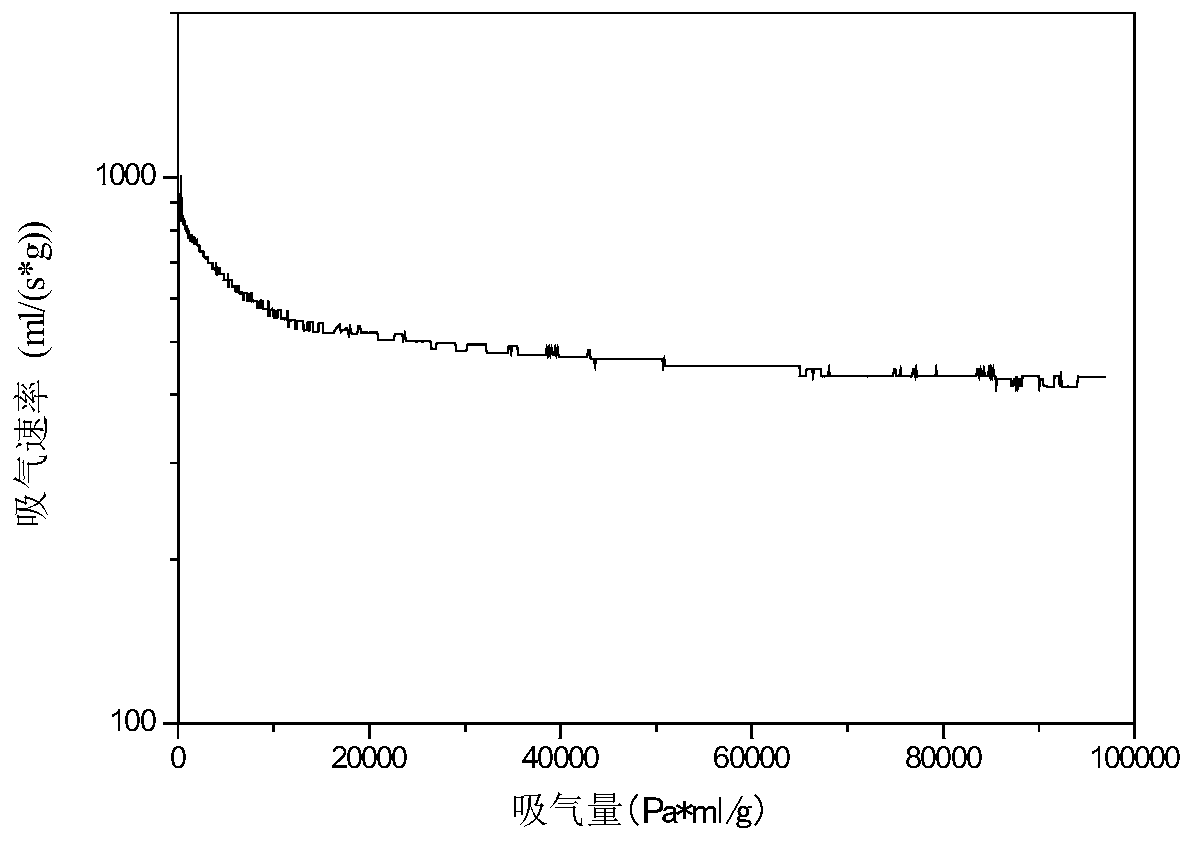

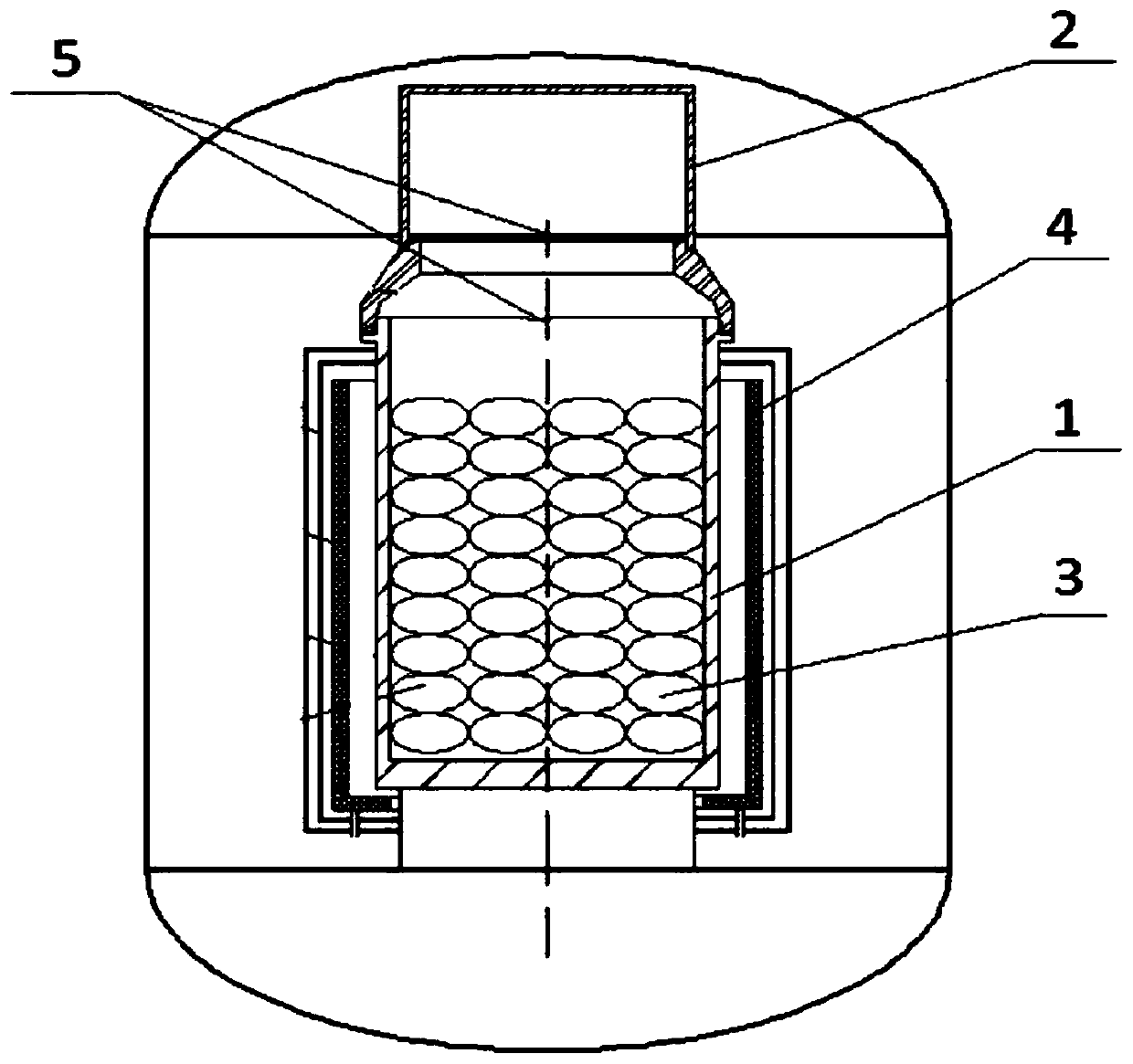

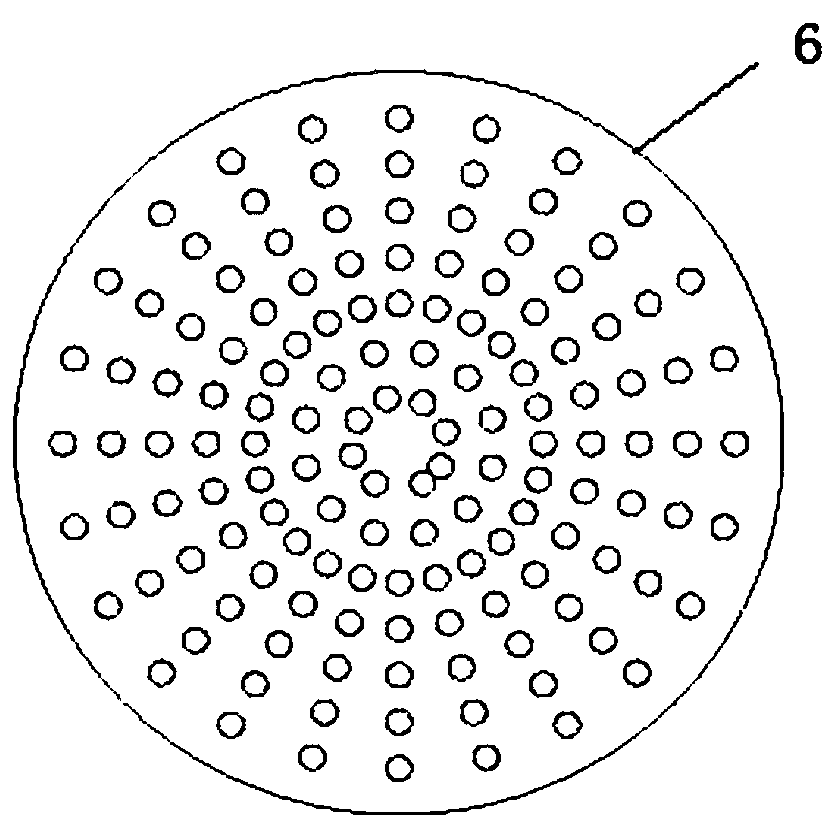

Multi-layer ring element with hydrogen absorption and desorption function and foreign gas adsorption function and preparation method thereof

ActiveCN111139374AImprove toughnessSolve the problem of component diffusionSpark gap detailsTitanium zirconiumManganese

The invention relates to a multi-layer ring element with a hydrogen absorption and desorption function and a foreign gas adsorption function and a preparation method thereof. In the element, a titanium-molybdenum alloy is used as a hydrogen absorption and desorption alloy, a titanium-zirconium-manganese-iron alloy is used as a foreign gas adsorption alloy, copper powder is used as a spacer layer,layer-by-layer pressing is performed in a mold to form a blank, and then sintering is performed to obtain the element. The element is used for hydrogen absorption and desorption and foreign gas removal of a pseudo-spark switch. The preparation method includes the steps: (1) smelting titanium and molybdenum to obtain a hydrogen absorption and desorption alloy ingot; (2) smelting titanium, zirconium, manganese and iron to obtain a foreign gas adsorption alloy ingot; (3) crushing the two alloy ingots separately for powdering, and grinding the two kinds of alloy powder and copper powder into powder separately; (4) under the protective atmosphere of argon, putting the different kinds of powder into the mold layer by layer sequentially to press the powder into the multi-layer ring element blank;and (5) sintering the ring blank into the element.

Owner:GRIMAT ENG INST CO LTD

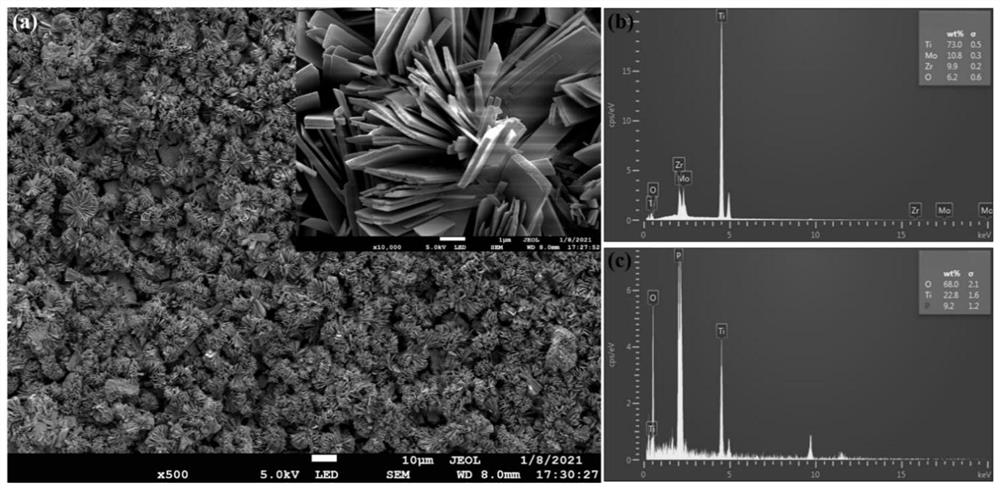

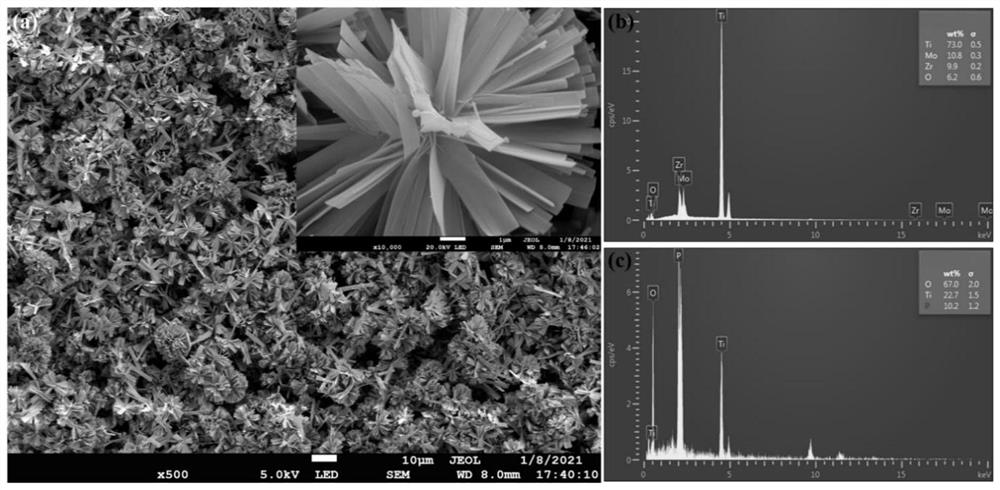

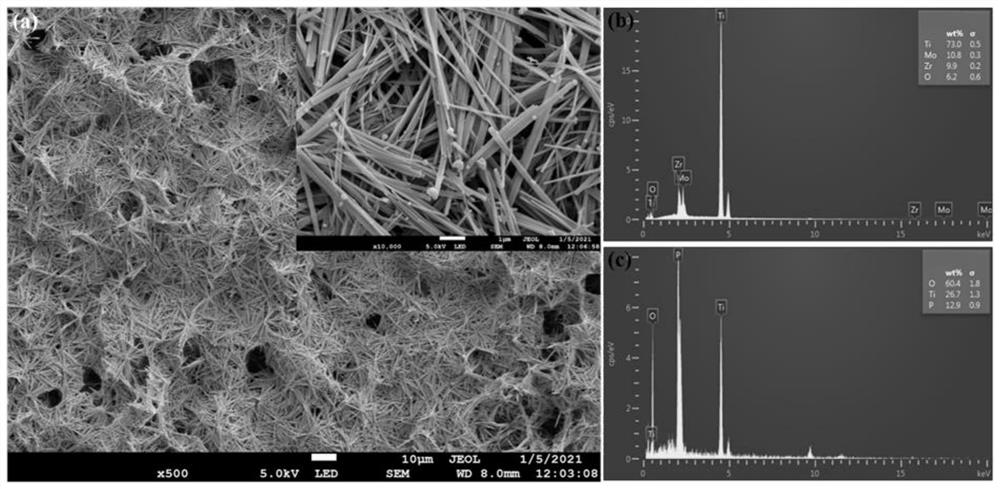

Titanium-molybdenum-zirconium metastable beta titanium alloy surface modification method

ActiveCN113106435ANo biohazardous elementsLow elastic modulusImpression capsDentistry preparationsAcid etchingTissue repair

The invention discloses a titanium-molybdenum-zirconium metastable beta titanium alloy surface modification method, and relates to the technical field of medical metal material surface functional modification. The method comprises the following steps: firstly, carrying out acid etching treatment on titanium-molybdenum-zirconium metastable beta titanium alloy, then putting the titanium-molybdenum-zirconium metastable beta titanium alloy into a mixed aqueous solution of H2O2 and H3PO4 for hydrothermal reaction, and finally preparing surface-modified titanium-molybdenum-zirconium metastable beta titanium alloy by controlling reaction conditions. According to the method, the main inorganic component P element of bone is successfully doped into the Ti-Zr-Mo alloy, so that the prepared titanium alloy material has low elastic modulus and high surface bioactivity, is free of biologically toxic elements, and has wide application prospects in the fields of clinical prosthodontics, implantation, orthodontics, hard tissue repair and the like.

Owner:CHINA UNIV OF MINING & TECH

Titanium-molybdenum-nickel alloy composite board and manufacturing method thereof

ActiveCN105128446AIncrease the number ofGood value for moneyMetal layered productsHydrogenNickel alloy

The invention discloses a titanium-molybdenum-nickel alloy composite board which is used for manufacturing a power plant chimney. The titanium-molybdenum-nickel alloy composite board comprises a titanium-molybdenum-nickel alloy board and a substrate steel board; the titanium-molybdenum-nickel alloy board is made of titanium-molybdenum-nickel alloy and prepared from, by weight, 0.2%-0.4% of molybdenum, 0.6%-0.9% of nickel, 0.08% of carbon, 0.15% of silicon, 0-0.015% of hydrogen, 0-0.2% of oxygen, 0.3% of ferrum and the balance titanium. According to the titanium-molybdenum-nickel alloy composite board, the structures of the titanium-molybdenum-nickel alloy board and the substrate steel board are more reasonable, the cost performance of the metal composite board for a power plant is improved, the life of the metal composite board is prolonged, the usage temperature is increased, the unit capacity is increased, the design requirements are completely met, and the economical effeciency is high. The invention further provides a manufacturing method of the composite board.

Owner:BAOJI TAICHENG METAL CO LTD

Vacuum smelting furnace and method for preparing high-purity metal ytterbium through one-time continuous reduction distillation

ActiveCN111424184ARaise the yield of rare earthReduce overflow rateYTTERBIUM OXIDECombustion chamber

The invention discloses a method for preparing high-purity metal ytterbium through one-time continuous reduction distillation. The method comprises the steps that a vacuum smelting furnace is adopted,a basic raw material pressing block is placed in a metal crucible, and titanium and molybdenum-manufactured double-plug plates are arranged at different temperature transition sections of a distillation system; a combustion chamber of the vacuum smelting furnace is vacuumized to be 10 Pa or below, current delivery and heating are carried out, the heating rate, and thermal insulation time are controlled for heating, metal lanthanum is used for thermal reduction on high-purity ytterbium oxide, a generated metal ytterbium is condensed in a receiver after being distilled by the double-plug plates, a diffusion pump is closed after distillation is completed, argon is filled, and cooling is conducted to a normal temperature according to the set cooling speed and time. The invention further discloses the vacuum smelting furnace. According to the method, stable operation of a distillation process is ensured, the metal ytterbium is low in overflow rate, the rare earth yield is high, impurity entrainment is effectively removed, and lanthanum impurities in the metal ytterbium are greatly reduced.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com