Display panel, preparation method thereof and display device

A display panel and display area technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of poor bonding between MTD and welding materials, and achieve the effects of solving poor bonding, reducing manufacturing costs, and reducing manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

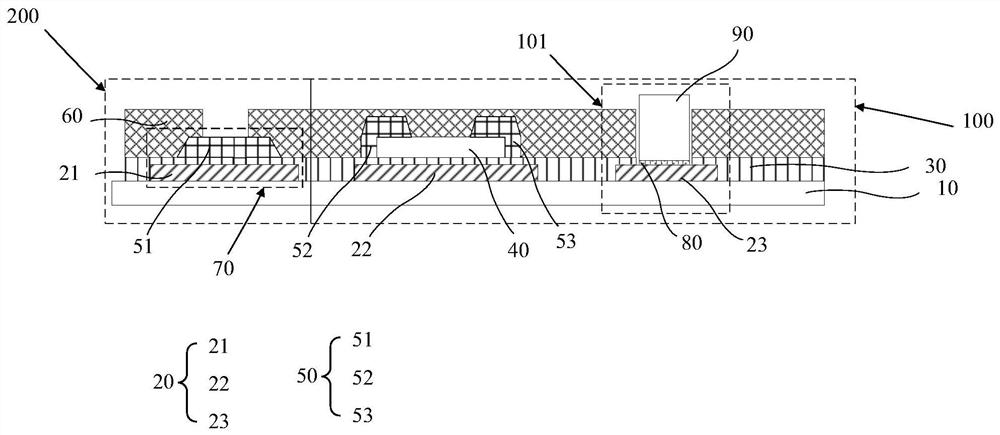

[0040] see figure 1 , a schematic structural diagram of the display panel provided by the embodiment of the present application.

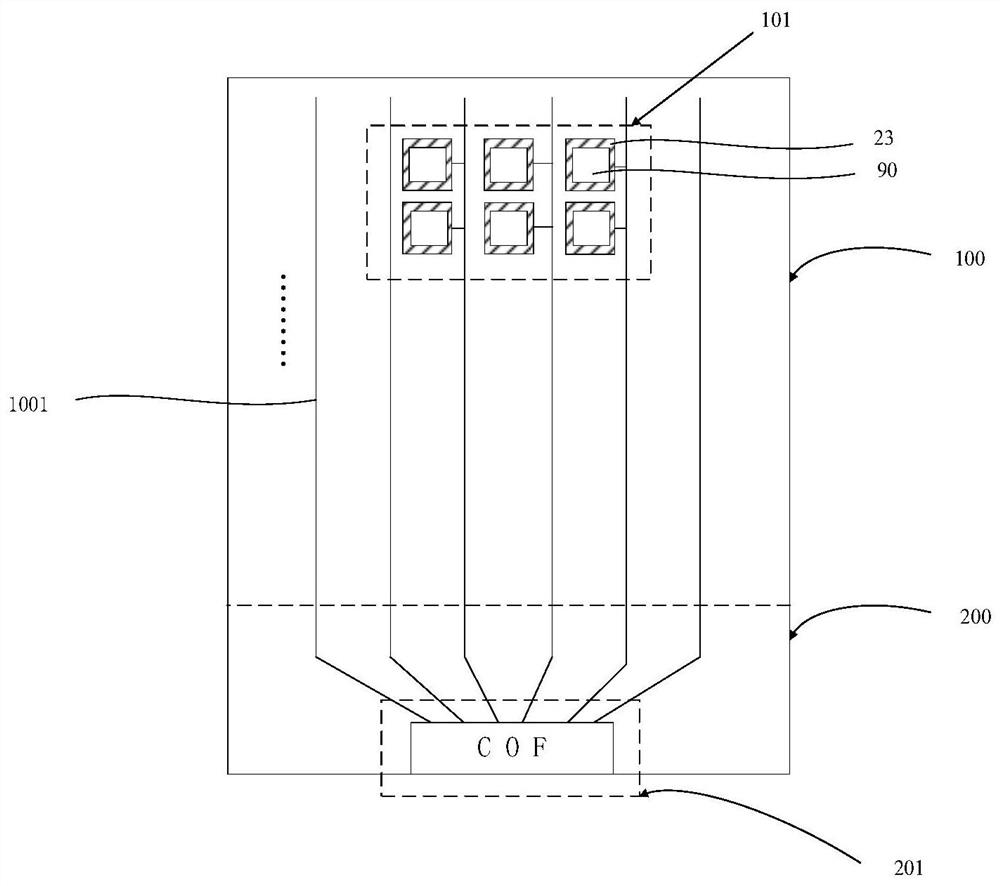

[0041] In this embodiment, the display panel includes a display area 100 and a non-display area 200 surrounding the display area 100 , and the display area 100 includes a plurality of pixel areas 101 .

[0042] The display panel includes a substrate 10; a first electrode layer 20 disposed above the substrate 10; a first insulating layer 30 disposed above the first electrode layer 20; an active layer disposed above the first insulating layer 30 40 ; a second electrode layer 50 disposed above the active layer 40 ; and a second insulating layer 60 disposed above the second electrode layer 50 .

[0043] In this embodiment, the substrate 10 is a PI substrate, mainly polyimide, and the PI material can effectively improve light transmittance.

[0044] In this embodiment, the first electrode layer 20 includes a first electrode 21 , a gate 22 and a weldin...

Embodiment 2

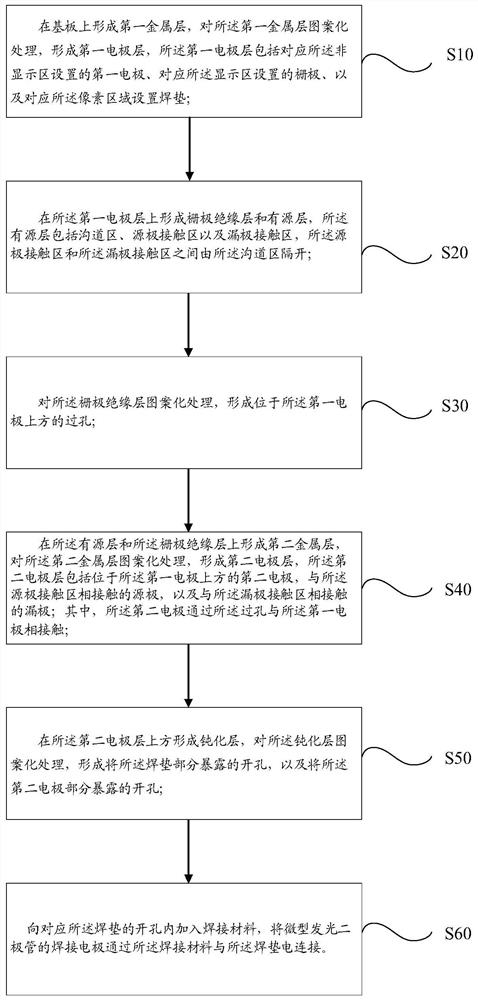

[0076] see image 3 , a flow chart of the steps of the manufacturing method of the display panel provided in the embodiment of the present application.

[0077] In this embodiment, the display panel includes a display area 100 and a non-display area 200 surrounding the display area 100 , and the display area 100 includes a plurality of pixel areas 101 .

[0078] The preparation method of the display panel includes:

[0079] Step S10: providing a substrate 10, forming a first metal layer on the substrate 10, patterning the first metal layer to form a first electrode layer 20, the first electrode layer 20 includes The first electrode 21 set at 200, the gate 22 set corresponding to the display area 100, and the pad 23 set corresponding to the pixel area 101, as Figure 4A shown.

[0080] In this embodiment, the substrate 10 is a PI substrate, mainly polyimide, and the PI material can effectively improve light transmittance.

[0081] In this embodiment, the material of the fir...

Embodiment 3

[0098] The present application also provides a display device, which includes the display panel described in Embodiment 1.

[0099] The display panel has been described in detail in Embodiment 1, and the description will not be repeated here.

[0100] The present application provides a display panel, a manufacturing method thereof, and a display device. The display panel includes a display area and a non-display area surrounding the display area, and the display area includes a plurality of pixel areas; the display panel includes a substrate and a The welding pad and the signal line on the substrate, the welding pad is arranged corresponding to the pixel area, and the welding pad is electrically connected to the signal line; the material of the welding pad includes molybdenum / copper laminate, molybdenum At least one of a titanium alloy / copper stack and a titanium-molybdenum-nickel alloy / copper stack; wherein, the welding electrodes on the micro light emitting diodes are electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com