Bone repair titanium-molybdenum-based hydroxyapatite composite material and preparation method thereof

A technology based on hydroxyapatite and hydroxyapatite, which is used in prosthesis, medical science and other directions, can solve the problems of low elastic modulus, mismatched mechanical properties, and high compressive strength, and achieves low elastic modulus and reduced The effect of tissue defects and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a titanium-molybdenum-based hydroxyapatite composite material for bone repair, the preparation method comprising the following steps:

[0036] (1) According to the mass percentage of Ti (purity: 99.99%, particle size: 500 mesh): 90%, Mo (purity: 99.99%, particle size: 400 mesh): 10%, weigh 18.00g Ti and 2.00g Mo powder respectively , take by weighing 0.40g stearic acid powder simultaneously;

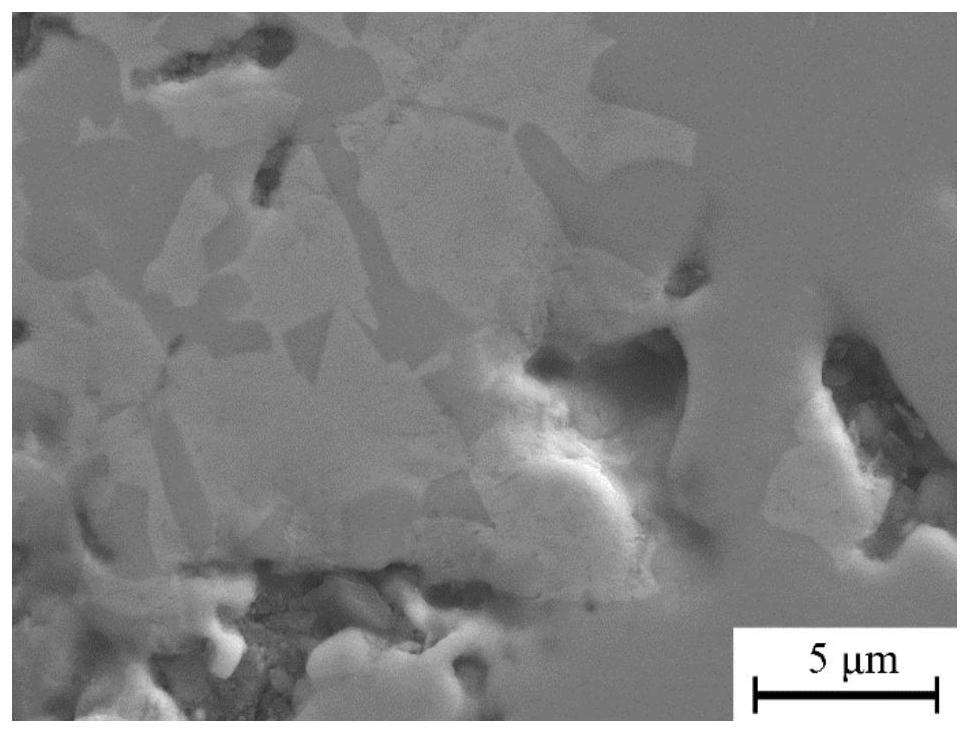

[0037](2) Grind the raw materials weighed in step (1) in the stainless steel ball mill tank of the planetary ball mill (the ball milling medium is stainless steel grinding balls with a diameter of 4-10mm, and the mass ratio of the ball to material is 10:1). The ball milling speed is 400r / min , the ball milling time is 6h, and the titanium-molybdenum metal powder with a fine particle size is obtained, and the particle size is 5-50 μm;

[0038] (3) Add 2.00g of hydroxyapatite powder (purity 99.99%, average particle diameter is 15 μ m spherical micron powder)...

Embodiment 2

[0043] The rest of the steps in this example are the same as in Example 1, except that 1.4 g of hydroxyapatite powder (a spherical micron-sized powder with a purity of 99.99% and an average particle size of 15 μm) is added to obtain a titanium-molybdenum-based hydroxyapatite composite material , Ti-10Mo / 7HA.

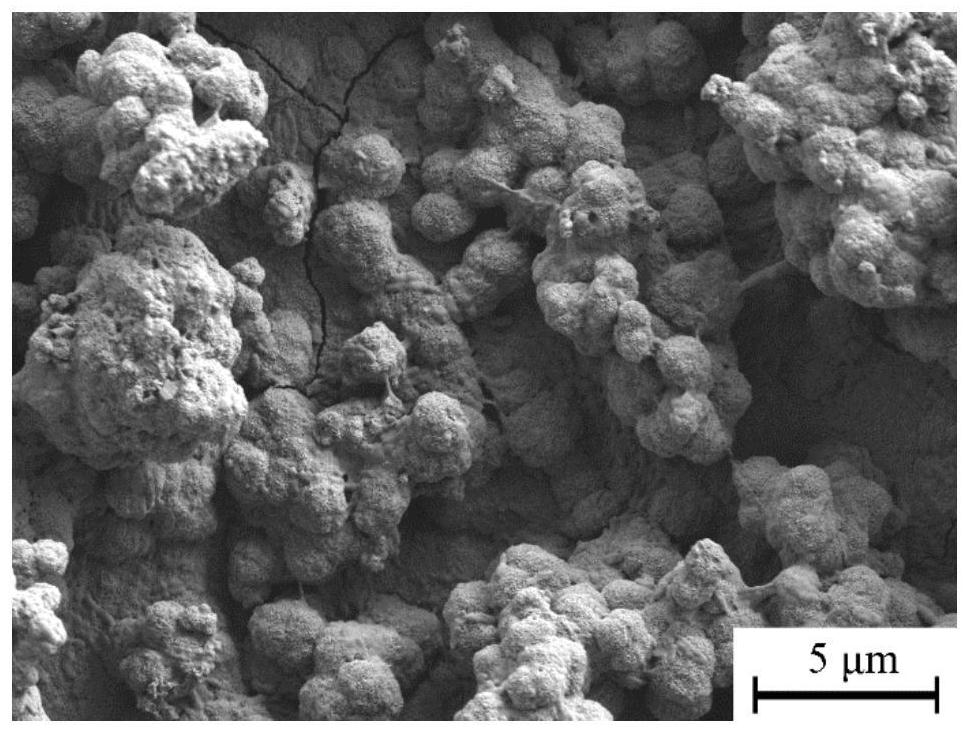

[0044] The density of the Ti-10Mo / 7HA composite material prepared in this example is 4.39g / cm 3 , the elastic modulus is 46.46GPa, and the compressive strength is 1153MPa. The biological activity of the composite material prepared in this embodiment is evaluated by using the in vitro biomimetic mineralization experiment. The sample is soaked in simulated body fluid at a temperature of 37°C. Change the solution once a day, soaking time is 7 days, if the surface deposits figure 2 The bone-like apatite layer shown shows that the material has good biological activity. Experimental results such as figure 2 As shown, a large amount of spherical bone-like apatite was depos...

Embodiment 3

[0046] The remaining steps of this embodiment are the same as in Example 1, except that 1.00 g of hydroxyapatite powder (a spherical micron-sized powder with a purity of 99.99% and an average particle size of 15 μm) is added to obtain a titanium-molybdenum-based hydroxyapatite composite material, Ti-10Mo / 5HA.

[0047] The density of the Ti-10Mo / 5HA composite material prepared in this embodiment is 4.51g / cm 3 , the modulus of elasticity is 48.69GPa, and the compressive strength is 1486MPa.

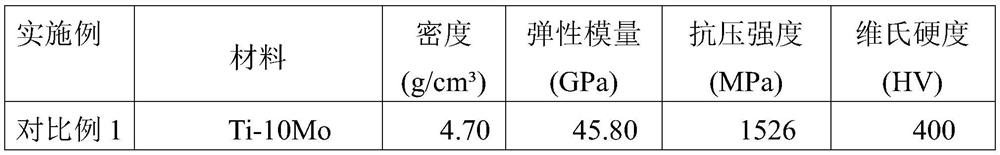

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com