Titanium-molybdenum-nickel alloys

A titanium-molybdenum-nickel and alloy technology, applied in the field of titanium-molybdenum-nickel alloys, can solve the problems of reducing plasticity, low yield, increasing the brittleness of titanium and titanium alloys, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

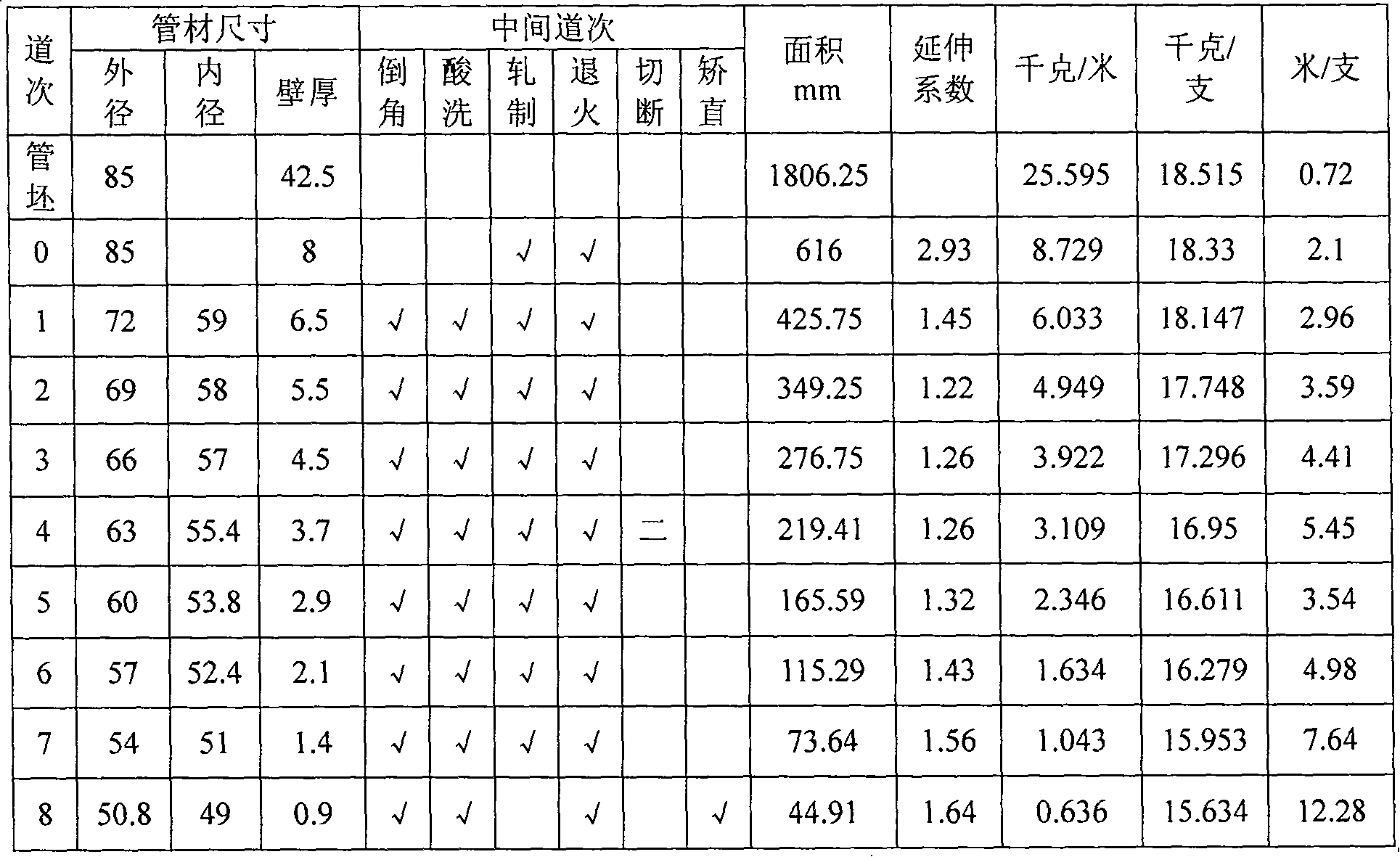

[0019] Example 1: A titanium-molybdenum-nickel alloy tube blank with a brand name of TA10 and a diameter of 85mm is used, and its composition is as follows: N: 0.009wt%, C: 0.025wt%, H: 0.004wt%, Fe: 0.07wt%, O: 0.07wt%, Mo: 0.38wt%, Ni: 0.8wt%, and the balance Ti, after piercing a bar with an outer diameter of 85mm, the outer diameter is 50.8mm and the wall thickness is 0.899mm through the production process steps in Table 1. A total of 100 pieces of ultra-long titanium alloy tubes with a length of 12.2 meters were fed, of which TA10 means titanium-molybdenum-nickel alloy.

[0020] Table 1 Process steps for producing ultra-long titanium alloy tubes

[0021]

[0022] After the above process steps, 5 cracks were found, among which 3 cracks were found in the first rolling of 72×6.5, and cracks occurred in the second rolling of 69×5.5, and the remaining 95 were all finished products. damage phenomenon.

Embodiment 2

[0023] Example 2. Using TA10, a titanium-molybdenum-nickel alloy tube blank with a diameter of 85mm, its composition is as follows: N: 0.0075wt%, C: 0.02wt%, H: 0.003wt%, Fe: 0.065wt%, 0:0.06wt% %, Mo: 0.35wt%, Ni: 0.75wt%, the remainder Ti, after being perforated by a bar with a diameter of 85mm, the outer diameter is 50.8mm, the wall thickness is 0.899mm, and the length is A total of 100 pieces of 12.2-meter-long titanium alloy pipes were fed, and only 3 pieces were found to be cracked, among which cracks appeared during the second rolling of 69×5.5, and the remaining 97 pieces were not damaged to the finished product.

Embodiment 3

[0024] Example 3: Using TA10, a titanium-molybdenum-nickel alloy tube blank with a diameter of 85mm, its composition is as follows: N: 0.006wt%, C: 0.015wt%, H: 0.0015wt%, Fe: 0.06wt%, O: 0.055wt% %, Mo: 0.3wt%, Ni: 0.7wt%, the remainder Ti, after being perforated by a bar with a diameter of 85mm, the outer diameter is 50.8mm, the wall thickness is 0.899mm, and the length is A total of 100 pieces of ultra-long titanium alloy tubes of 12.2 meters were fed in, and it was found that only one piece was cracked, and the remaining 99 pieces were not damaged when they reached the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com