Titanium-molybdenum carbide ceramic powder and preparation method thereof

A technology of titanium carbide, molybdenum and ceramic powder, which is applied in the field of ceramics to achieve the effect of single phase composition and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of titanium molybdenum carbide ceramic powder, comprising the following steps:

[0033] a Melting: Melting titanium powder and molybdenum powder into Ti in a non-consumable vacuum melting furnace x Mo 1-x Alloy; Ti x Mo 1-x In the alloy, the weight content of each element is: Ti5.3-81.8wt%, Mo18.2-94.7%, wherein, 0.1<x<1;

[0034] b hydrogenation pulverization: remove Ti first x Mo 1-x The oxide layer on the surface of the alloy is washed and dried, and then the obtained Ti x Mo 1-x The alloy is hydrogenated at 400-450°C and 3.5-4.5MPa to obtain Ti x Mo 1-x alloy, then cooled to room temperature and pulverized to obtain Ti x Mo 1-x Powder;

[0035] c with carbon: the Ti x Mo 1-x The powder and carbon powder are mixed, then dried and pressed to obtain Ti x Mo 1-x C blank; wherein, the amount of carbon powder added is Ti x Mo 1-x 13.16%-22.73% of powder mass;

[0036] d Sintering reaction: the Ti ...

Embodiment 1

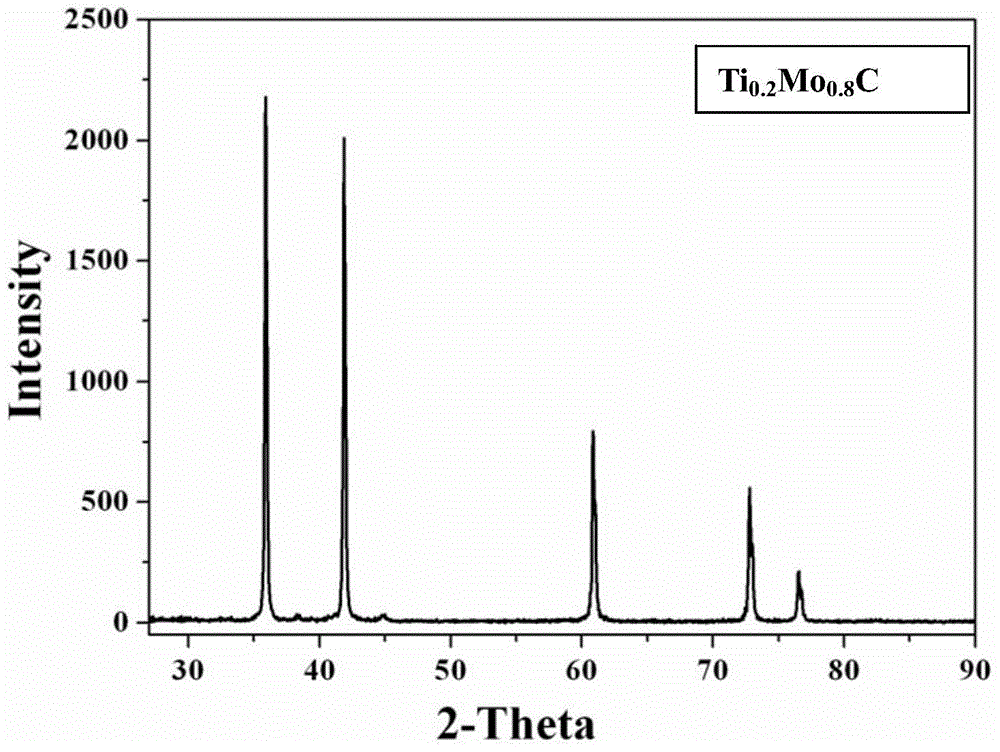

[0060] Embodiment 1 Adopt the method of the present invention to produce titanium carbide molybdenum ceramics

[0061] Take 3.3 grams of titanium powder and 26.7 grams of molybdenum powder and mix them manually on a tablet press to form a block, put it into a crucible in a non-consumable vacuum melting furnace, and evacuate to 5×10 -3 MPa, fill the vacuum chamber with high-purity argon (>99.9%), and vacuumize to 5×10 after repeated three times -3 MPa, argon gas is introduced into the vacuum chamber; the alloy is smelted by ignition arc, and each sample is smelted by repeated flipping 3 times.

[0062] Cool to room temperature and take out the sample to remove the alloy surface layer with a polishing electric drill, wash and dry with absolute ethanol, put the sample in a hydrogenation device, vacuumize for 10 minutes, heat to 400°C and continue heating for 20 minutes, turn off the vacuum pump, and put 4Mpa hydrogen to make the sample undergo hydrogenation reaction; vacuumize a...

Embodiment 2

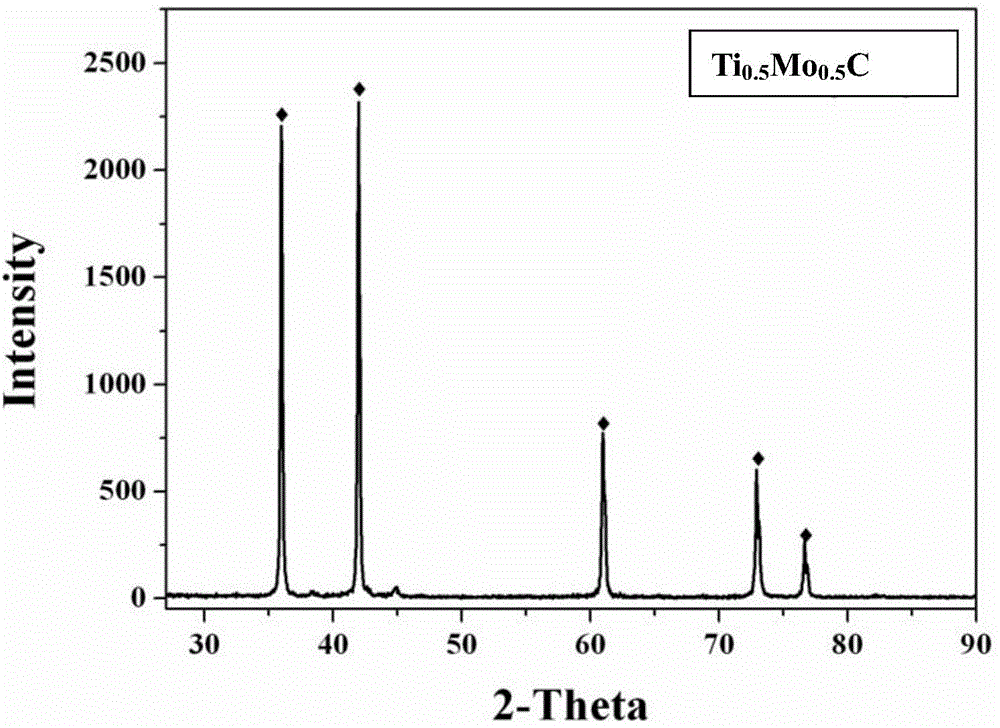

[0065] Embodiment 2 Adopt the method of the present invention to produce titanium carbide molybdenum ceramics

[0066] Take 10 grams of titanium powder and 20 grams of molybdenum powder and mix them manually on a tablet press to form a block, put it into a crucible in a non-consumable vacuum melting furnace, and evacuate to 5×10 -3 MPa, fill the vacuum chamber with high-purity argon (>99.9%), and vacuumize to 5×10 after repeated three times -3 MPa, argon is introduced into the vacuum chamber. The arc is ignited, the alloy is smelted, and each sample is smelted 3 times by repeated flipping.

[0067] Cool to room temperature and take out the sample to remove the alloy surface layer with a polishing electric drill, wash and dry with absolute ethanol, put the sample in a hydrogenation device, vacuumize for 10 minutes, heat to 400°C and continue heating for 20 minutes, turn off the vacuum pump, and put 4Mpa hydrogen to make the sample undergo hydrogenation reaction. After 20 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com