Multi-layer ring element with hydrogen absorption and desorption function and foreign gas adsorption function and preparation method thereof

A technology for absorbing impurities, absorbing and releasing hydrogen, applied to electrical components, spark gap parts, spark gaps, etc., can solve problems such as powder falling, fragmentation, and mutual diffusion of functional metal components The effect of increasing the amount of hydrogen and improving the cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

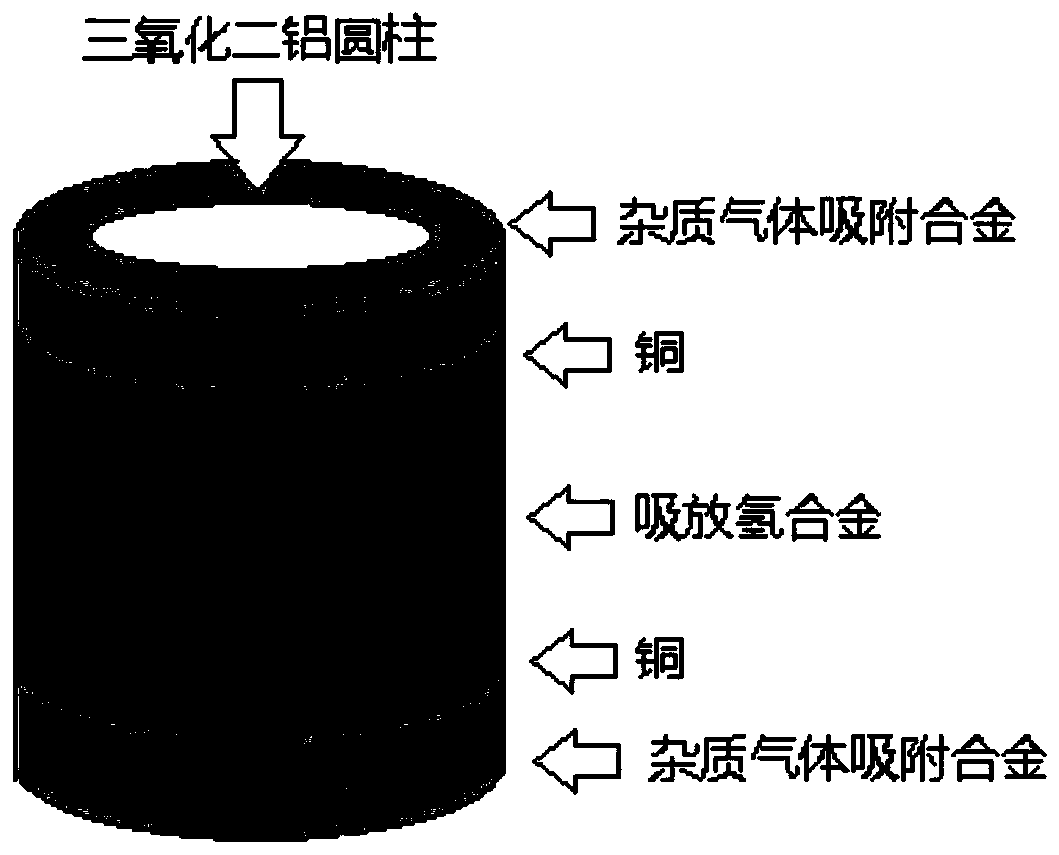

[0033] In the multi-layer annular element having the functions of hydrogen absorption and desorption and adsorption of impurity gas, titanium-molybdenum alloy is used as hydrogen absorption and desorption alloy, titanium-zirconium-manganese-ferroalloy is used as alloy for adsorption of impurity gas, and copper is used as a separation layer. 300 mesh powder.

Embodiment 2

[0035] The multi-layer annular element with both hydrogen storage and impurity gas adsorption functions prepared by the present invention, its hydrogen absorption and desorption alloy component, that is, TiMo alloy, is smelted in a vacuum suspension furnace at 1600 ° C, and the alloy ingot obtained after the furnace is cooled is protected by argon. In the atmosphere, it is pulverized to 20 mesh by crushing ball mill, and the powder enters the jet mill. The grinding gas is argon (purity ≥ 99.999%), the pressure is 0.50 MPa, and the sorting frequency is 60 Hz. The powder is collected to obtain a TiMo powder with a diameter of ≤50 μm.

Embodiment 3

[0037] The element prepared by the present invention has both hydrogen absorption and desorption and impurity gas adsorption functions. The impurity gas adsorption alloy component, namely TiZrMnFe alloy, is smelted in a vacuum suspension furnace at 1400 ° C, and the alloy ingot obtained after furnace cooling is placed in an argon protective atmosphere. After being crushed to 20 mesh by crushing ball mill, the powder enters the jet mill, the grinding gas is argon (purity ≥ 99.999%), the pressure is 0.50MPa, and the sorting frequency is 20Hz. The particle diameter of the collected powder is ≤100μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com