Method for automatic argon arc welding of titanium-molybdenum-nickel alloy thick filament with diameter of 2.0 mm

A technology of argon arc welding, titanium molybdenum nickel, applied in welding equipment, arc welding equipment, metal processing, etc., can solve the problems of inert gas poisoning of operators, low efficiency of welding process, lack of fusion, etc., and achieve stable and reliable welding quality , Reduce welding line energy, reduce the effect of welding joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

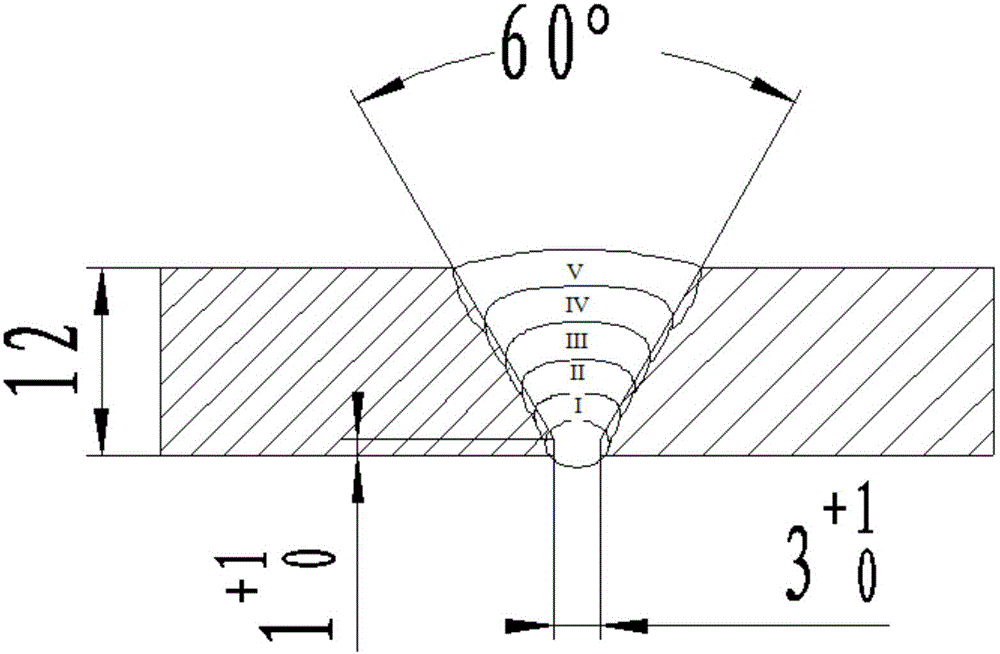

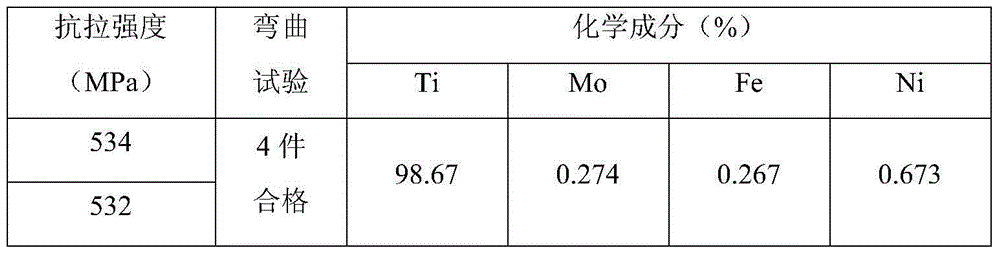

[0022] Embodiment 1: a kind of titanium-molybdenum-nickel alloy Thick wire automatic argon arc welding method, a titanium-molybdenum-nickel alloy Thick wire automatic argon arc welding method, first pre-treat the parts to be welded to form a V-shaped welding groove, the groove angle is 62°, and the blunt edge is 1.5mm; then the welding wire, the groove and the inner surfaces on both sides Carry out cleaning to remove rust, grease and dust; then carry out root welding layer welding and cover layer welding in sequence, wherein the cover layer includes I-V layers.

[0023] In the port pretreatment of the welding plate, manual argon arc is used to seal the gap of the titanium-molybdenum-nickel alloy.

[0024] The welding of the root welding layer adopts a manual argon arc welding process. In order to ensure the quality of welding, the welding process parameters are controlled as follows: the welding material specification is The welding current is 200A, the welding voltage is...

Embodiment 2

[0037] A titanium-molybdenum-nickel alloy Thick wire automatic argon arc welding method, firstly pre-treat the parts to be welded to form a V-shaped welding groove, the groove angle is 60°, and the blunt edge is 1mm; then the welding wire, the groove and the inner surfaces on both sides are processed Clean up to remove rust, grease and dust; then perform root welding and cover layer welding in sequence, wherein the cover layer includes I-V layers.

[0038] In the port pretreatment of the welding plate, manual argon arc is used to seal the gap of the titanium-molybdenum-nickel alloy.

[0039] The welding of the root welding layer adopts a manual argon arc welding process. In order to ensure the quality of welding, the welding process parameters are controlled as follows: the welding material specification is The welding current is 160A, the welding voltage is 15V, and the welding speed is 100mm / min.

[0040] The welding of the cover surface layer I adopts an automatic argon...

Embodiment 3

[0047] A titanium-molybdenum-nickel alloy Thick wire automatic argon arc welding method, firstly pre-treat the parts to be welded to form a V-shaped welding groove, the groove angle is 65°, and the blunt edge is 2mm; then the welding wire, the groove and the inner surfaces on both sides are processed. Clean up to remove rust, grease and dust; then perform root welding and cover layer welding in sequence, wherein the cover layer includes I-V layers.

[0048] In the port pretreatment of the welding plate, manual argon arc is used to seal the gap of the titanium-molybdenum-nickel alloy.

[0049] The welding of the root welding layer adopts a manual argon arc welding process. In order to ensure the quality of welding, the welding process parameters are controlled as follows: the welding material specification is The welding current is 220A, the welding voltage is 16V, and the welding speed is 120mm / min.

[0050] The welding of the cover surface layer I adopts an automatic argo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com