Titanium-molybdenum-zirconium metastable beta titanium alloy surface modification method

A β-titanium alloy and surface modification technology, used in pharmaceutical formulations, metal material coating processes, dental preparations, etc., can solve the problems that the preparation technology cannot be realized, and achieve low elastic modulus, high surface biological activity, and broad application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

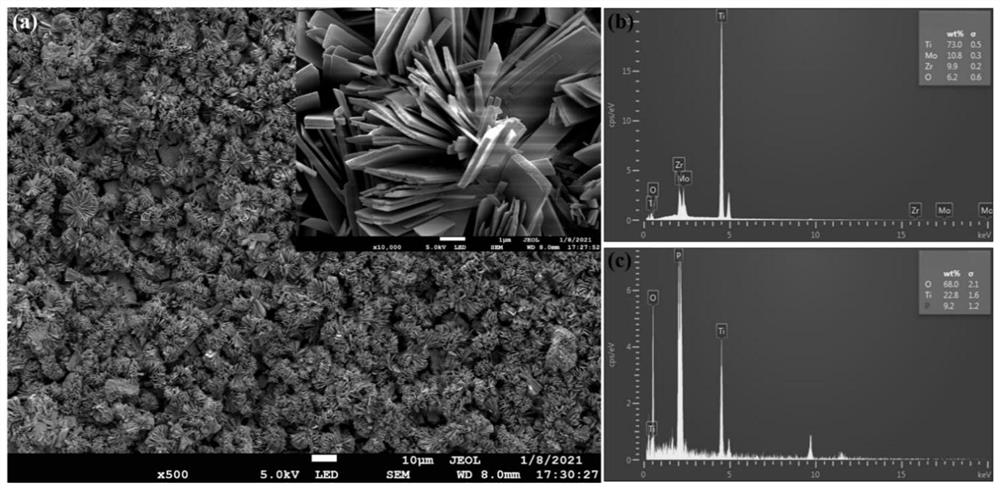

Embodiment 1

[0045] Cut the Ti-12Mo-10Zr alloy into a circular piece of Ф10mm×1mm, and polish it with 400-2000 mesh sandpaper in turn; soak the polished Ti-12Mo-10Zr in hydrofluoric acid, nitric acid and water with a volume ratio of Acid etching treatment in a mixed solution of 1:3:5 for 5 minutes for chemical polishing, followed by ultrasonic cleaning with acetone, absolute ethanol and ultrapure water for 30 minutes, respectively, took out the Ti-12Mo-10Zr alloy sheet, and placed it at a constant temperature of 37 °C.

[0046] Then, the Ti-12Mo-10Zr alloy sheet cleaned after the above pretreatment was placed in a polytetrafluoroethylene reaction kettle by a high-energy hydrothermal method, and the mass ratio was 27%H 2 o 2 +3%H 3 PO 4 Put the mixed aqueous solution into the reaction kettle, tighten the lid of the kettle to keep it airtight, and put the closed reaction kettle into an electric constant temperature blast dryer to react for 24 hours. The reaction temperature is set at 100°C...

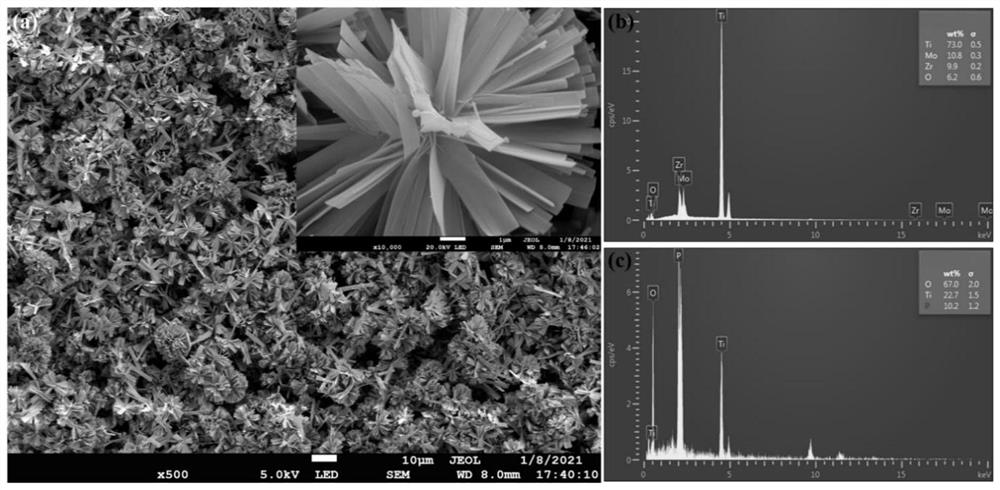

Embodiment 2

[0048] Cut the Ti-12Mo-10Zr alloy into a circular piece of Ф10mm×1mm, and polish it with 400-2000 mesh sandpaper in turn; soak the polished Ti-12Mo-10Zr in hydrofluoric acid, nitric acid and water with a volume ratio of Acid etching treatment in a mixed solution of 1:3:5 for 5 minutes for chemical polishing, followed by ultrasonic cleaning with acetone, absolute ethanol and ultrapure water for 30 minutes respectively, and then placed at a constant temperature of 37 °C.

[0049] Then, the Ti-12Mo-10Zr alloy sheet cleaned after the above pretreatment was placed in a polytetrafluoroethylene reaction kettle by a high-energy hydrothermal method, and the mass ratio was 27%H 2 o 2 +3%H 3 PO 4 Put the mixed aqueous solution into the reaction kettle, tighten the lid of the kettle to keep it airtight, and put the closed reaction kettle into an electric constant temperature blast dryer to react for 24 hours. The reaction temperature is set at 140°C and the reaction pressure is 150kpa. ...

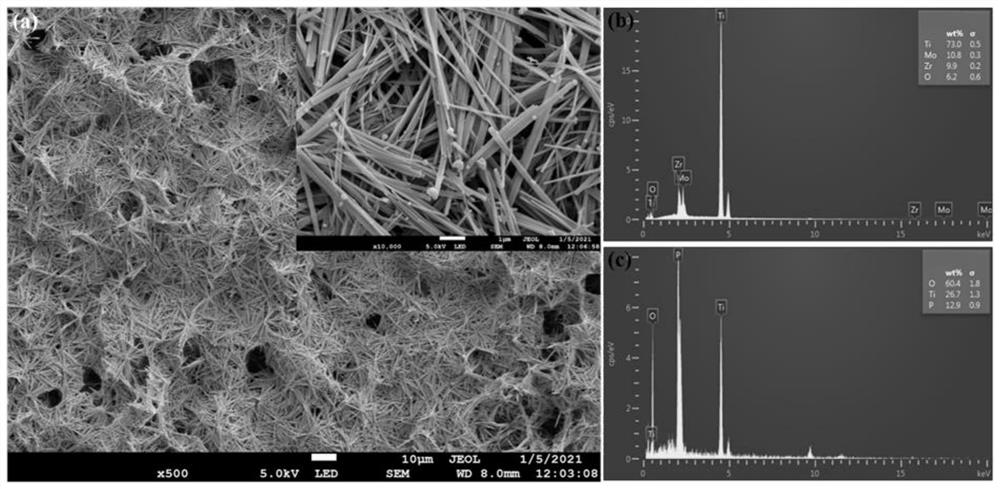

Embodiment 3

[0051] Cut the Ti-12Mo-10Zr alloy into a circular piece of Ф10mm×1mm, and polish it with 400-2000 mesh sandpaper in turn; soak the polished Ti-12Mo-10Zr in hydrofluoric acid, nitric acid and water with a volume ratio of The 1:3:5 mixed solution was acid-etched for 5 minutes for chemical polishing, followed by ultrasonic cleaning with acetone, absolute ethanol and ultrapure water for 30 minutes respectively, and the Ti-12Mo-10Zr alloy sheet was taken out and placed at a constant temperature of 37 °C.

[0052] Then the Ti-12Mo-10Zr alloy sheet cleaned after the above pretreatment was placed in a pressure cooker lined with polytetrafluoroethylene by high-energy hydrothermal method, and the mass ratio was 27%H 2 o 2 +3%H 3 PO 4 Put the mixed aqueous solution into the reaction kettle, tighten the lid of the kettle to keep it airtight, and put the closed reaction kettle into an electric constant temperature blast dryer to react for 24 hours. The reaction temperature is set at 180°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Horizontal width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com