Aluminum-titanium-molybdenum intermediate alloy and preparation method thereof

A technology of master alloy and aluminum-titanium, which is applied in the field of aluminum-titanium-molybdenum master alloy and its preparation, can solve the problems of large reaction heat effect, etc., and achieve the effects of good alloy uniformity, uniform and stable chemical composition, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

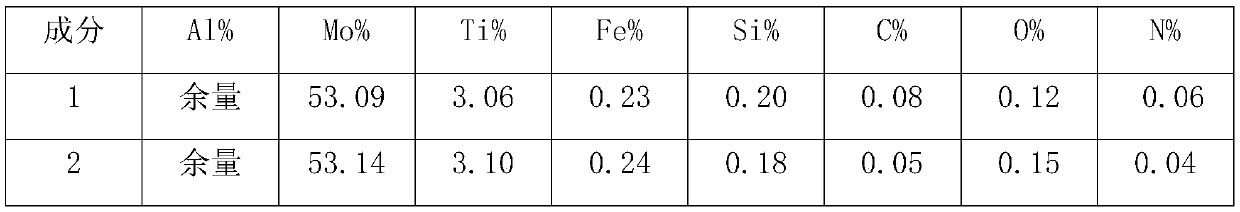

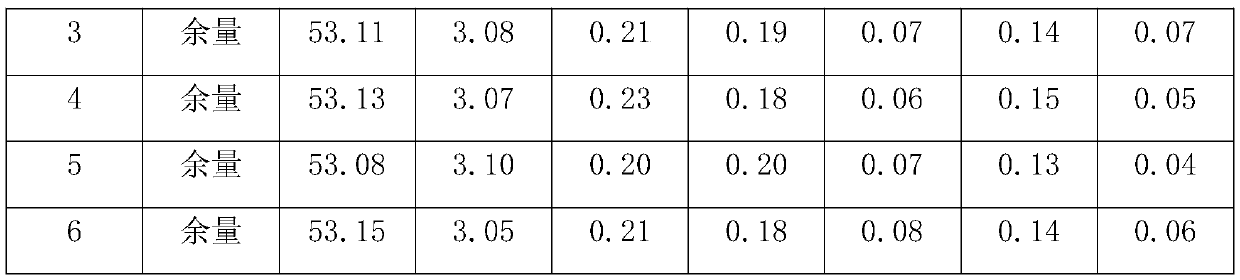

Embodiment 1

[0040] Embodiment 1 of the present invention discloses a method for preparing an aluminum-titanium-molybdenum master alloy, and the adopted technical scheme is as follows:

[0041] An aluminum-titanium-molybdenum master alloy, the specific steps of its preparation method are as follows:

[0042] 1. Dry aluminum powder, molybdenum trioxide and calcium fluoride, drying temperature: 118°C, drying time: 20 hours;

[0043] 2. Raw material ratio: 78.00kg of aluminum, 75.75kg of molybdenum trioxide, and 9.23kg of calcium fluoride. Put the raw materials into the V-shaped mixer and mix them well to ensure sufficient contact between raw materials;

[0044] 3. Put the uniformly mixed charge into the built-up magnesia brick crucible, ignite and react, and after cooling for 6 hours, dismantle the furnace, take out the alloy ingot, and weigh it;

[0045] 4. After removing the slag layer and oxide film on the surface of the alloy ingot, crush and finish it to 5-20mm, and obtain the aluminum...

Embodiment 2

[0052] Embodiment 2 of the present invention discloses a method for preparing an aluminum-titanium-molybdenum master alloy, and the adopted technical scheme is as follows:

[0053] An aluminum-titanium-molybdenum master alloy, the specific steps of its preparation method are as follows:

[0054] 1. Dry aluminum powder, molybdenum trioxide and calcium fluoride, drying temperature: 119°C, drying time: 18 hours;

[0055] 2. Raw material ratio: aluminum 76.69kg, molybdenum trioxide 79.59kg, calcium fluoride 10.94kg, put the raw materials into the V-shaped mixer, and mix them well to ensure sufficient contact between raw materials;

[0056] 3. Put the evenly mixed charge into the built-up magnesia brick crucible, ignite and react, and after cooling for 6 hours, dismantle the furnace, take out the alloy ingot, and weigh it;

[0057] 4. After removing the slag layer and oxide film on the surface of the alloy ingot, crush and finish it to 5-20mm, and obtain the aluminum-molybdenum ma...

Embodiment 3

[0064] Embodiment 3 of the present invention discloses a method for preparing an aluminum-titanium-molybdenum master alloy, and the adopted technical scheme is as follows:

[0065] An aluminum-titanium-molybdenum master alloy, the specific steps of its preparation method are as follows:

[0066] 1. Dry aluminum powder, molybdenum trioxide and calcium fluoride, drying temperature: 120°C, drying time: 16 hours;

[0067] 2. Raw material ratio: 76.10kg of aluminum, 81.96kg of molybdenum trioxide, and 12.64kg of calcium fluoride. Put the raw materials into the V-shaped mixer and mix them well to ensure sufficient contact between raw materials;

[0068] 3. Put the evenly mixed charge into the built-up magnesia brick crucible, ignite and react, and after cooling for 6 hours, dismantle the furnace, take out the alloy ingot, and weigh it;

[0069] 4. After removing the slag layer and oxide film on the surface of the alloy ingot, crush and finish it to 5-20mm, and obtain the aluminum-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com