Block titanium-molybdenum-niobium alloy and preparation method thereof

A technology of niobium alloy and titanium molybdenum is applied in the field of bulk titanium molybdenum niobium alloy and its preparation, which can solve the problems of reduced grain boundary strength, easy occurrence of brittle fracture, abandoning solid solution strengthening, etc., and achieves the effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

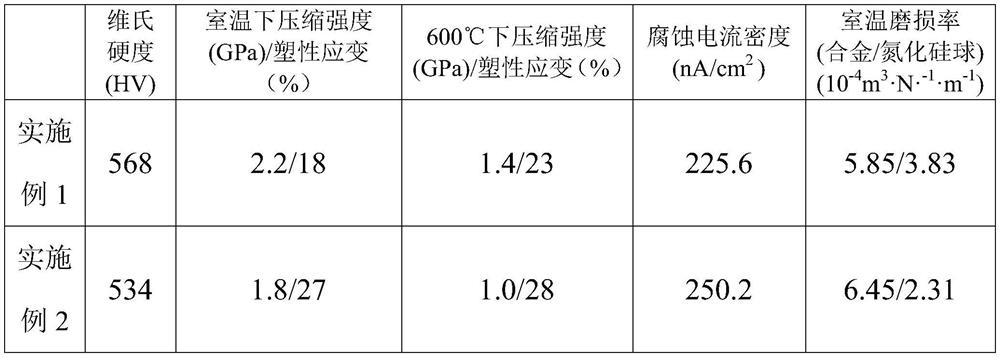

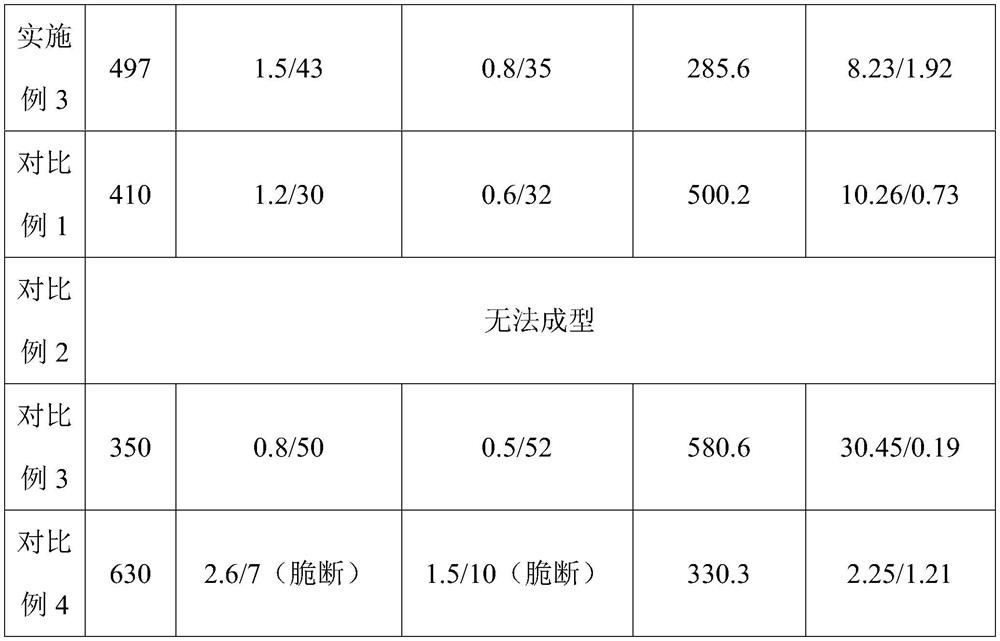

Embodiment 1

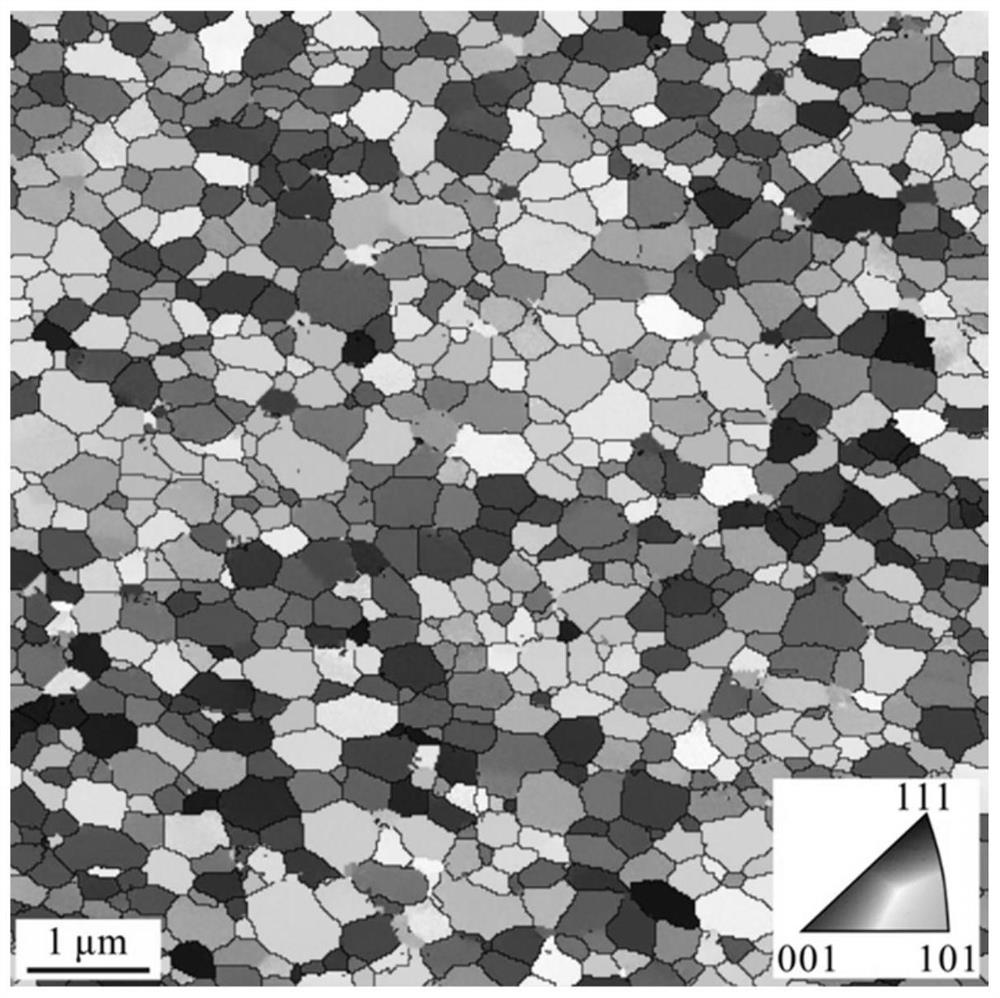

[0064] (1) In a glove box full of argon protection, by mass percentage, 30% titanium powder, 30% molybdenum powder and 40% niobium powder are mixed, and the amount of titanium powder, molybdenum powder and niobium powder The purity is 99.5%, 99.5% and 99.8%; the alloy powder is placed in a high-energy ball mill, the mass ratio of the ball and the alloy powder is controlled to be 6:1, the rotation frequency of the high-energy ball mill fixture is 17Hz, and the rotation speed is 1700r / min; High energy ball milling for 15 hours to obtain titanium molybdenum niobium solid solution alloy powder;

[0065] (2) Place the alloy powder obtained in step (1) in a graphite mold, put it into a discharge discharge plasma sintering furnace, and heat it up to 850°C at a rate of 100°C / min for 5min under a vacuum of 0.01Pa. During the sintering process, a constant pressure of 60 MPa is applied axially to the alloy powder, and after the sintering is completed, the temperature is lowered under vac...

Embodiment 2

[0069] (1) In a glove box full of argon protection, by mass percentage, 25% titanium powder, 35% molybdenum powder and 40% niobium powder are mixed, and the amount of titanium powder, molybdenum powder and niobium powder The purities are 99.5%, 99.5% and 99.8% respectively; the alloy powder is placed in a high-energy ball mill, the mass ratio of the ball to the alloy powder is controlled to be 8:1, the rotation frequency of the fixture of the high-energy ball mill is 17Hz, and the rotation speed is 1750r / min; High energy ball milling for 12 hours to obtain titanium molybdenum niobium solid solution alloy powder;

[0070] (2) Place the alloy powder obtained in step (1) in a graphite mold, put it into a discharge discharge plasma sintering furnace, and heat it up to 900°C at a rate of 100°C / min for 5min under a vacuum of 0.01Pa. During the sintering process, a constant pressure of 45 MPa is applied axially to the alloy powder. After the sintering is completed, the temperature is...

Embodiment 3

[0074](1) In a glove box full of argon protection, by mass percentage, 35% titanium powder, 30% molybdenum powder and 35% niobium powder are mixed, and the amount of titanium powder, molybdenum powder and niobium powder The purities are 99.5%, 99.5% and 99.8% respectively; the alloy powder is placed in a high-energy ball mill, the mass ratio of the ball and the alloy powder is controlled to be 5:1, the rotation frequency of the fixture of the high-energy ball mill is 17Hz, and the rotation speed is 1750r / min; High energy ball milling for 18 hours to obtain titanium molybdenum niobium solid solution alloy powder;

[0075] (2) Place the alloy powder obtained in step (1) in a graphite mold, put it into a discharge discharge plasma sintering furnace, and heat it up to 950°C at a rate of 100°C / min for 8 minutes under a vacuum of 0.01Pa. During the sintering process, a constant pressure of 60 MPa is applied axially to the alloy powder, and after the sintering is completed, the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com