Glass mold material for small-hole blowing and pressing and preparation method thereof

A glass mold material and charge technology, which is used in glass manufacturing equipment, glass blowing, glass forming, etc., can solve the problems of wear resistance not keeping up with the requirements and insufficient hardness, so as to meet the needs of lightweight, improve hardness and The effect of toughness, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the present invention will be further described below in conjunction with the examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

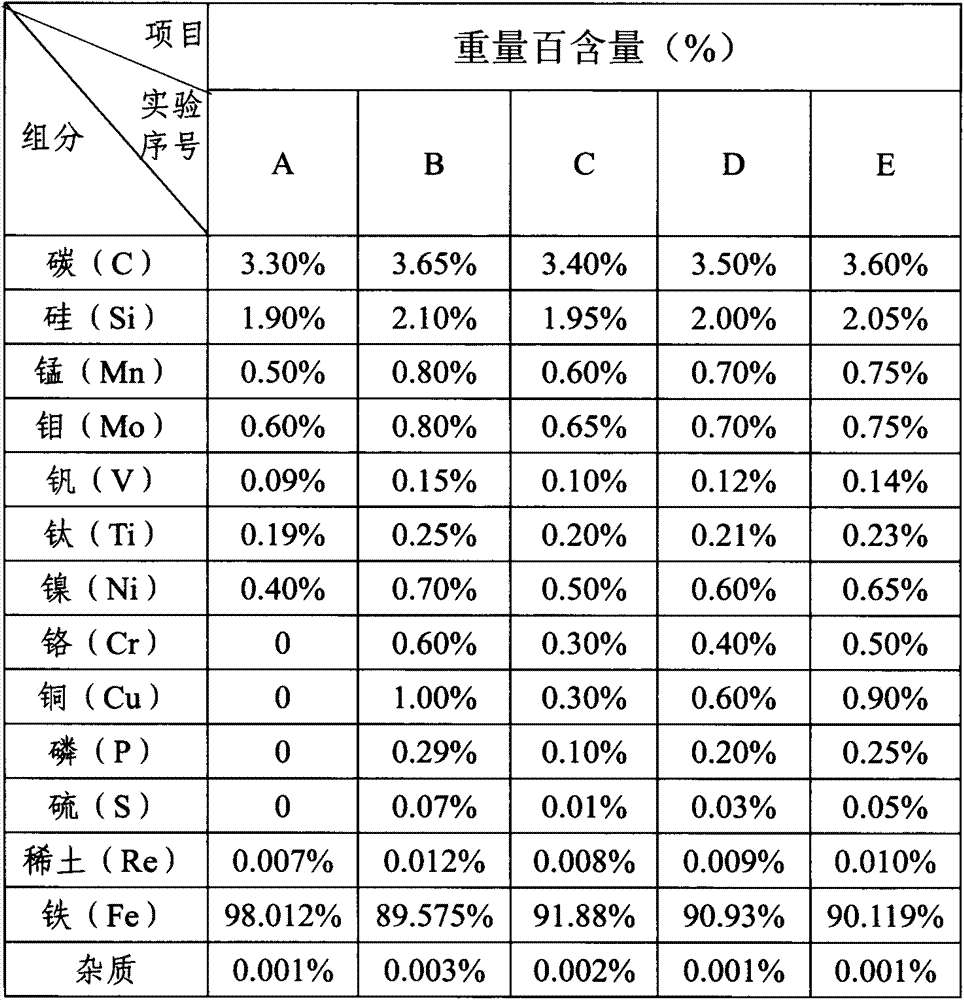

[0031] As shown in Table 1, it is an example of the chemical composition and mass percentage of the small mouth pressure blown glass mold material of the present invention.

[0032] Table 1 Chemical composition and mass percentage of small mouth pressure blown glass mold materials

[0033]

[0034] The metallographic structure of the small mouth pressure blown glass mold material of the present invention is as follows: the inner shape is 90% D-type graphite, the outer shape is 90% A-type graphite, and the middle is transitional D+A type graphite.

[0035] The matrix of the small mouth pressure blown glass mold material of the present invention is: greater than 85% ferrite +...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com