Lanthanum cerium iron alloy for producing rare earth steel and preparation method thereof

A ferroalloy and lanthanum-cerium technology, which is applied in the field of lanthanum-cerium-iron alloy for producing rare earth steel and its preparation, can solve the problems of high local concentration of rare earth metals, high smelting temperature requirements, affecting product consistency, etc., and achieves broad development and market prospects. The effect of high product quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

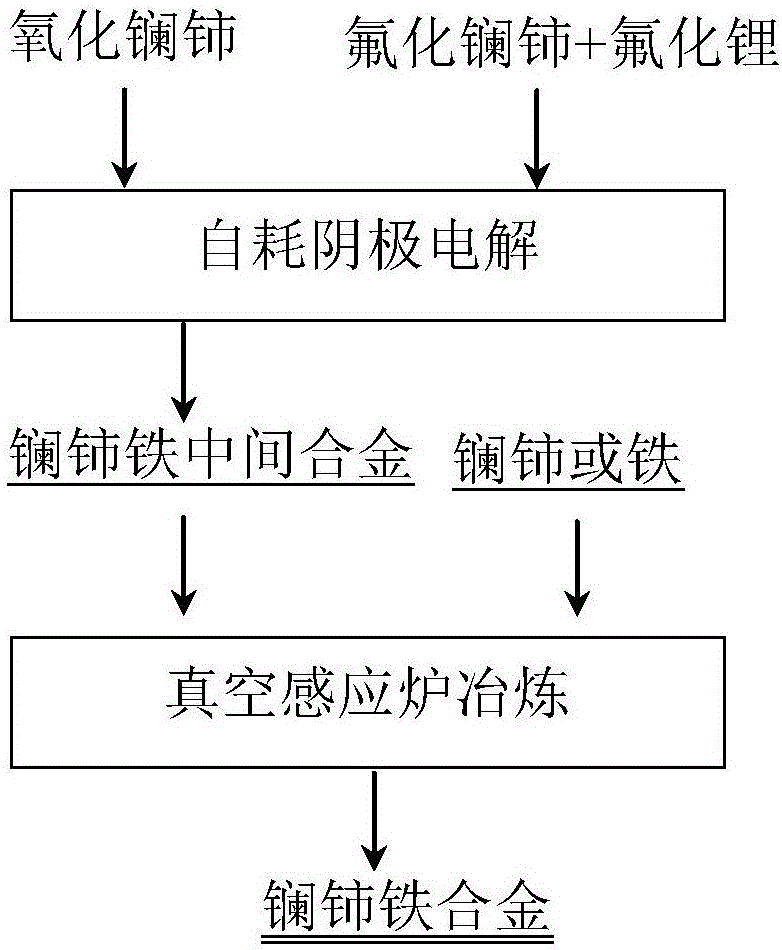

[0035] The preparation technology of the ferro-lanthanum cerium alloy for producing rare earth steel comprises the following steps:

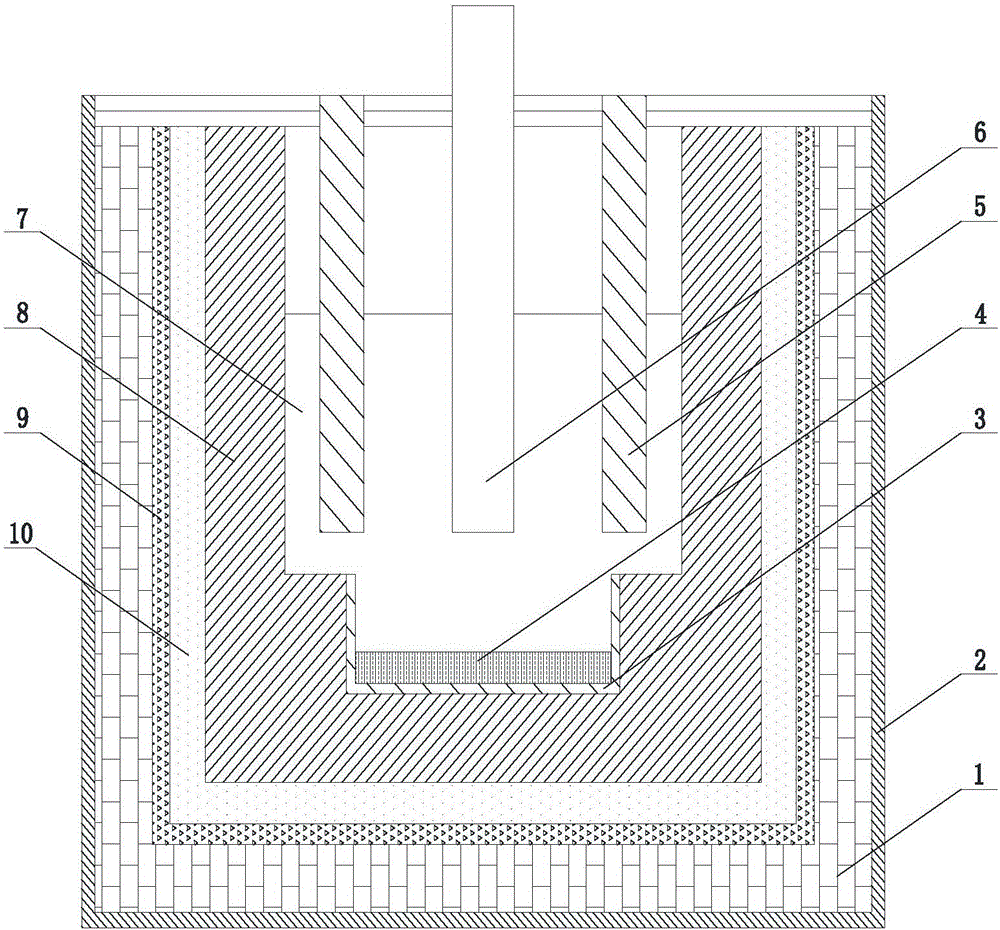

[0036] Step 1: Graphite is used as the electrolytic cell, the graphite plate is used as the anode, the iron rod is used as the self-consumable cathode, and there is a receiver containing the alloy under the cathode;

[0037] The material of the receiver can be one of iron, rare earth oxide, and boron nitride.

[0038] Step 2: In the fluoride molten salt electrolyte system of lanthanum cerium fluoride (a mixture of lanthanum fluoride and lanthanum cerium fluoride) and lithium fluoride, using lanthanum cerium oxide (a mixture of lanthanum oxide and cerium oxide) as the electrolytic raw material, Passing direct current electrolysis to obtain lanthanum-cerium-iron master alloy;

[0039] Step 3: Using the lanthanum-cerium-iron master alloy and iron as raw materials, the lanthanum-cerium-iron alloy meeting the requirements is prepared by melting.

...

Embodiment 1

[0046] A Φ650mm circular graphite electrolytic cell is used. The anode is composed of four graphite plates. The lanthanum cerium fluoride in the electrolyte is 85wt%, and the lithium fluoride is 15wt%. The cathode is a pure iron rod with a diameter of 70mm. The average current intensity is 2800A. 0.5-1.0A / cm 2 , cathode current density 7-9A / cm 2, the electrolysis temperature is maintained at 900-1000 ° C, continuous electrolysis for 150 hours, 887 kg of lanthanum cerium oxide is consumed, and 864 kg of lanthanum cerium iron master alloy is obtained, the average lanthanum cerium content is 90%, the current efficiency is 90%, and the rare earth yield is 95%. The composition results are shown in Table 1.

[0047] Table 1 Analysis results of lanthanum-cerium-iron master alloy composition / wt%

[0048] RE Fe C O P S Si mn 90.0 9.85 0.0085 0.0094 <0.01 <0.005 0.012 <0.005

[0049] Using the lanthanum-cerium-iron master alloy prepared in this exam...

Embodiment 2

[0053] A Φ650mm circular graphite electrolytic cell is used. The anode is composed of four graphite plates. The lanthanum cerium fluoride in the electrolyte is 85wt%, and the lithium fluoride is 15wt%. The cathode is a pure iron rod with a diameter of 70mm. The average current intensity is 2800A. 0.5-1.0A / cm 2 , cathode current density 8-10A / cm 2 , the electrolysis temperature is maintained at 900-1000 ° C, continuous electrolysis for 150 hours, 887 kg of lanthanum cerium oxide is consumed, and 864 kg of lanthanum cerium iron master alloy is obtained, the average lanthanum cerium content is 95%, the current efficiency is 90%, and the rare earth yield is 95%. The composition results are shown in Table 3.

[0054] Table 3 lanthanum-cerium-iron master alloy composition analysis results / wt%

[0055] RE Fe C O P S Si mn 95.0 4.85 0.0085 0.0094 <0.01 <0.005 0.012 <0.005

[0056] Using the lanthanum-cerium-iron master alloy prepared in this examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com