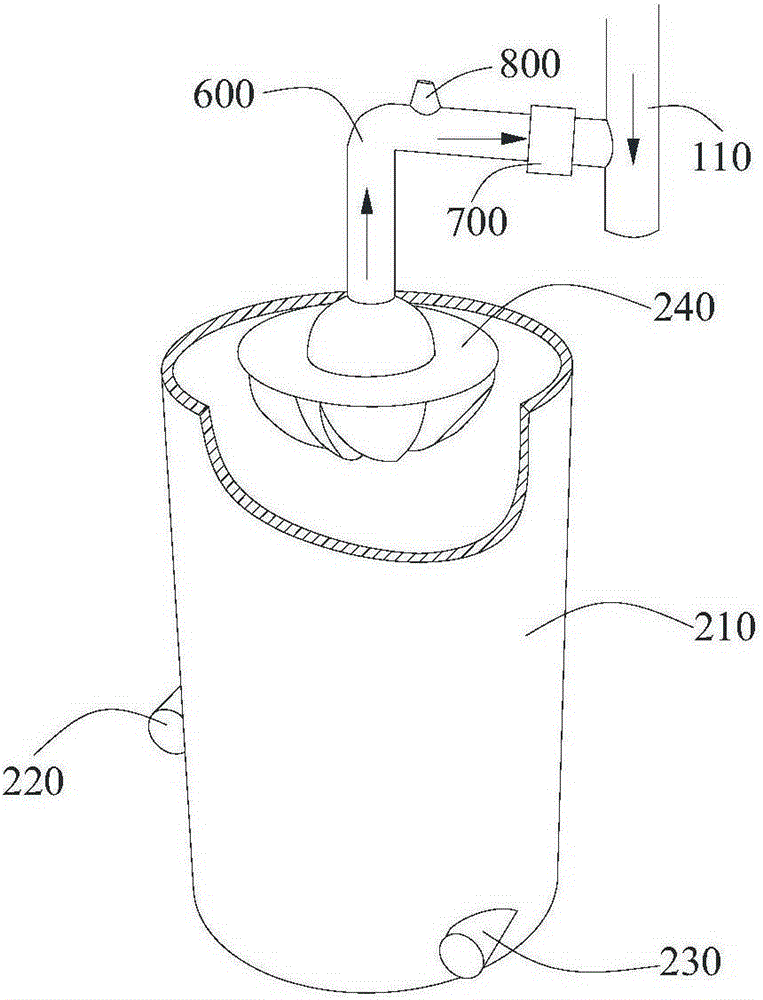

Bubble removing system

A technology for collecting bubbles and closing containers, which is applied in separation methods, liquid degassing, degassed water/sewage treatment, etc. It can solve the problems of low efficiency and achieve the effects of low cost, high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

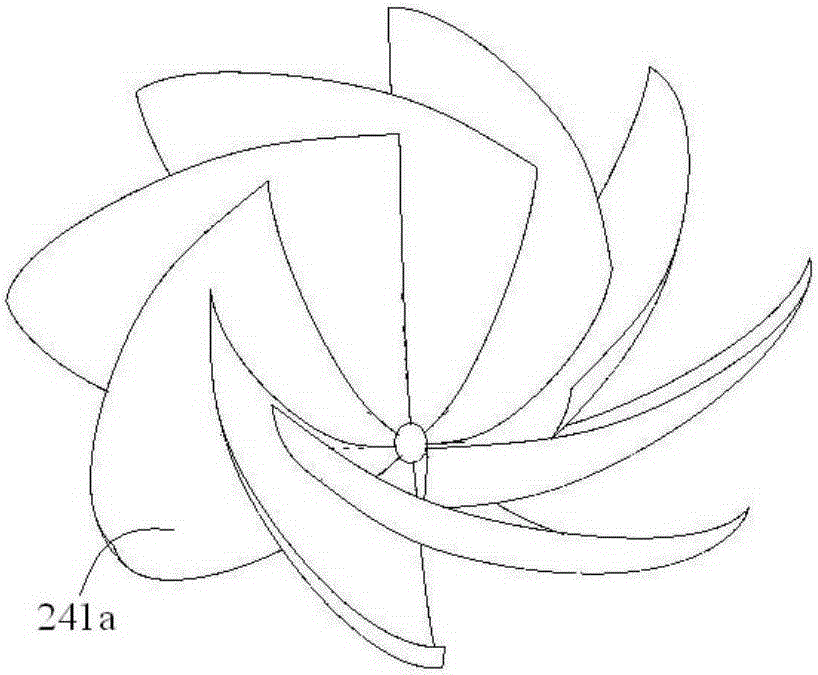

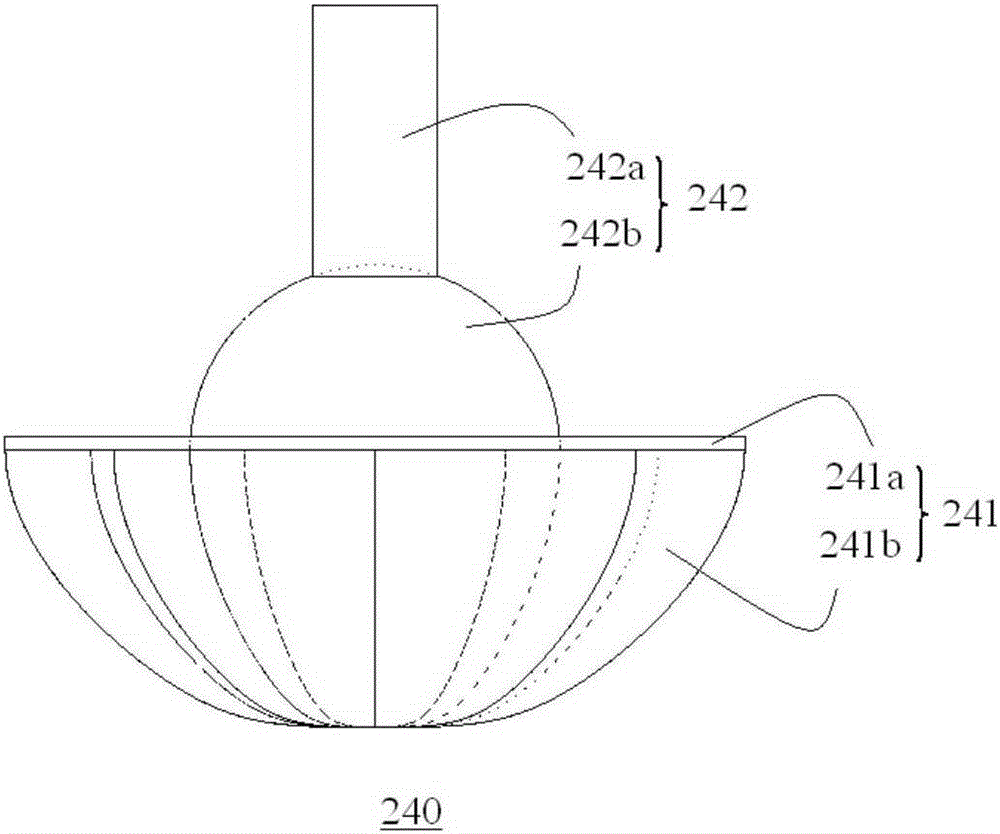

Method used

Image

Examples

Embodiment approach

[0070] As a preferred embodiment of the present invention, the spiral polymer membrane pipeline 130 is arranged around the first closed container 210 . Only when the outer diameter of the first closed container 210 of the main defoaming device 200 is smaller than the inner diameter of the spiral polymer membrane pipeline 130, the first closed container 210 of the main defoaming device 200 can be arranged on the spiral polymer membrane. in the space surrounded by the pipe. The smaller the diameter, the faster the jelly-like substance rises in the first closed container, and the faster the jelly-like substance rotates in the first closed container, so that the jelly-like substance obtains a larger volume in the main defoaming device 200. The centrifugal force is more conducive to the separation of air bubbles and colloidal substances. In addition to the above advantages, placing the first closed container 210 in the space surrounded by the spiral polymer membrane pipeline can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com