Water-based paint defoaming equipment

A water-based paint and defoaming technology, which is applied in the directions of foam dispersion/prevention, liquid degassing by vibration, and liquid degassing, etc., can solve problems such as weak effect, and achieve the effect of simple structure, convenient operation and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

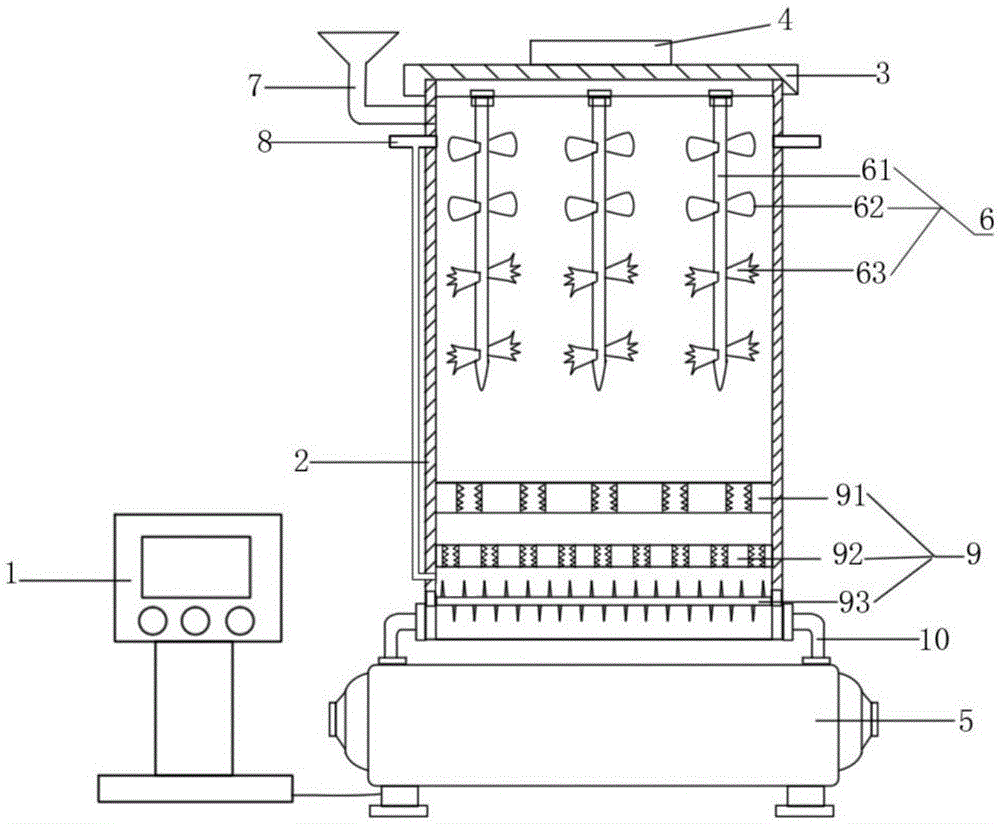

[0017] Such as figure 1 As shown, the water-based paint defoaming equipment includes a control device (1), a liquid storage tank (2), a sealing cover (3), a motor (4), and a discharge tank (5), and is characterized in that: the control device ( 1) It is connected to the motor (4) through the power supply. When in use, it can be switched, adjusted and set directly through the control panel of the control device. The sealing cover (3) is installed on the top of the liquid storage tank (2), and the motor (4) is installed above the outside of the sealing cover (3); a variable speed stirring device is installed on the top of the liquid storage tank (2) (6), feed inlet (7) and exhaust hole (8), during use, can adjust the speed of variable-speed stirring device according to demand, described variable-speed stirring device (6) is made up of stirring shaft (61), stirring blade (62 ) and gear stirring blades (63); a multi-stage filter defoaming layer (9) is installed at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com