In-furnace deep denitration process, denitration agent and preparation method of denitration agent

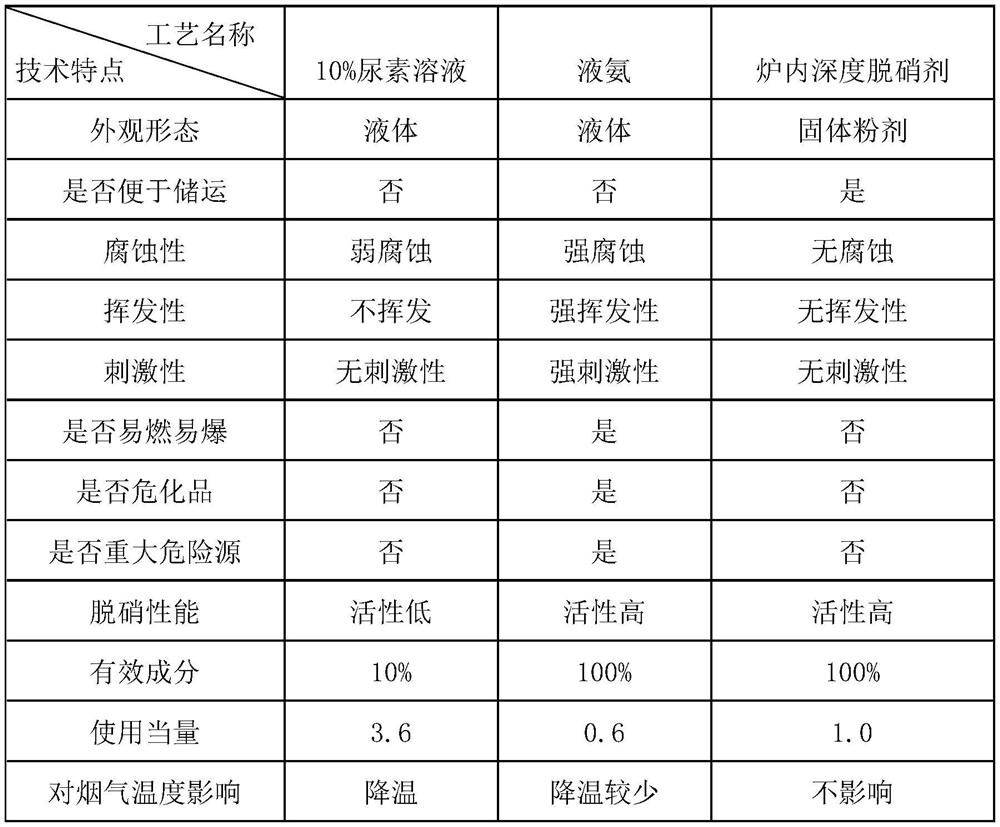

A denitration agent and denitration technology, applied in the field of denitrification, can solve the problems of short service life, failure to meet environmental protection requirements, high operation and maintenance costs, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

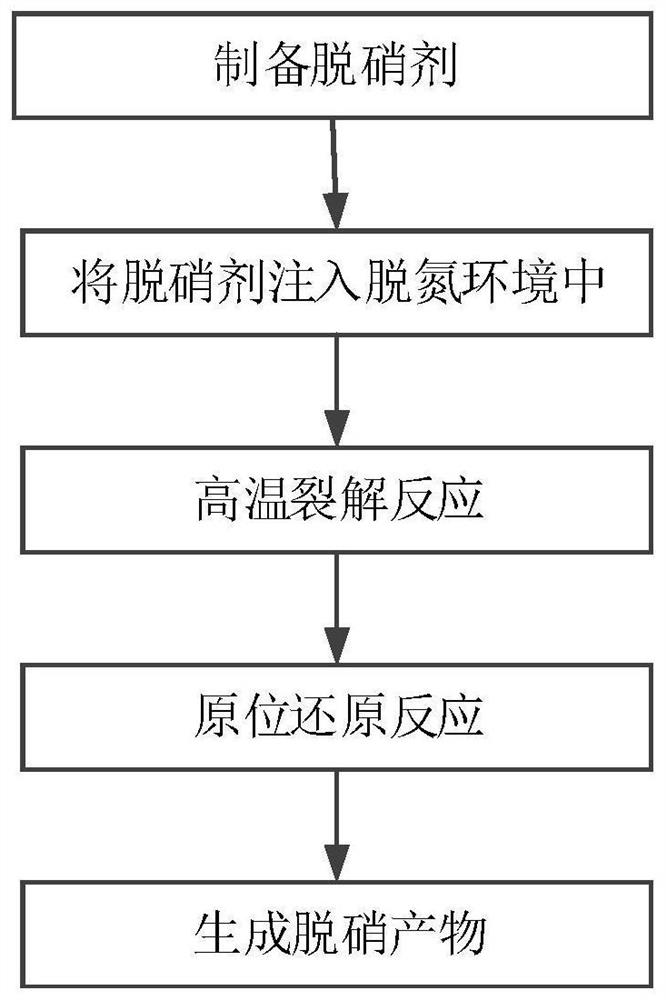

Method used

Image

Examples

preparation example Construction

[0036] Further, the present invention provides a method for preparing a denitrification agent, comprising: mixing urea, double crystal ammonia, talc powder, polyacrylic acid, and kaolin in water; heating the mixed solution to 120°C and stirring rapidly; mixing the raw materials Finally, a polymerization reaction occurs, so that the amino component in the twin crystal ammonia is polymerized on the polymer material in the raw material; after drying at a high temperature, it is dried; the dried powder is added to the reactor, the temperature is raised to 180 ° C, and the pressure is increased to two Atmospheric pressure, after fully reacting for 80 minutes until the finished product comes out of the pan.

[0037] Part II: List some examples

Embodiment 1

[0039] The denitrification agent is delivered to the powder through the powder conveying reaction system (including the denitrification agent silo, equipped with weighing devices, heat tracing devices, rapping devices, arch breaking devices, high and low material level alarms, buffer hoppers, agitators, etc.) The body is automatically cleaned in the spray gun, and then the powder denitrification agent is sprayed from the spray gun into the 600 °C furnace (that is, in the denitrification environment) to perform deep denitrification. The denitration agent is prepared from the following raw materials in parts by mass: 7 parts of urea; 2 parts of twin crystal ammonia; 2 parts of talcum powder; 3 parts of polyacrylic acid; and 1 part of kaolin.

Embodiment 2

[0041] The denitrification agent is delivered to the powder automatic cleaning spray gun through the powder delivery reaction system, and then the powder denitrification agent is sprayed from the spray gun into the 650°C furnace (that is, in the denitrification environment) to perform deep denitrification. The denitration agent is prepared from the following raw materials in parts by mass: 6 parts of urea; 1 part of twin crystal ammonia; 2 parts of talcum powder; 2 parts of polyacrylic acid; 1 part of kaolin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com